The C-More HMI Panel software uses virtual components called Objects. These objects are programmable to simulate the functions that you require on your automation project. Pushbuttons, switches, meters, and graphs are just a few of the objects that are available to you.

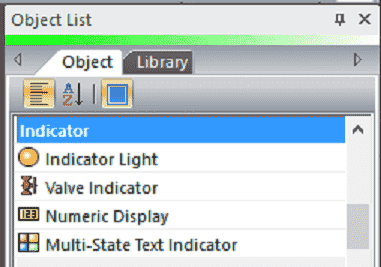

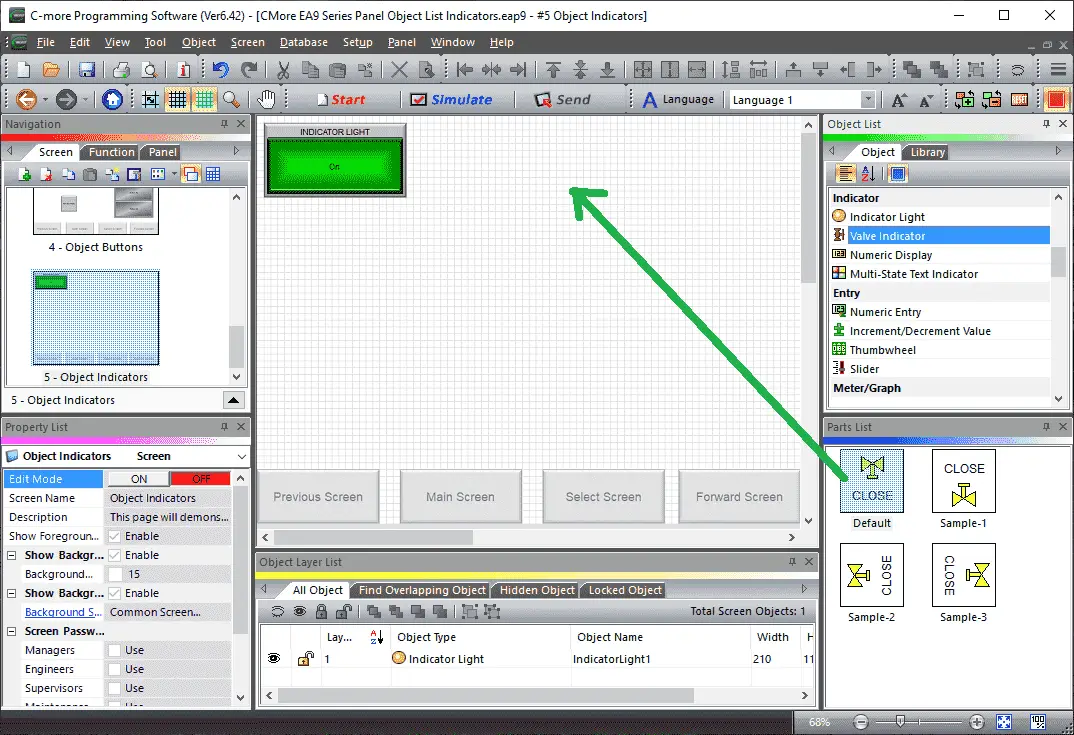

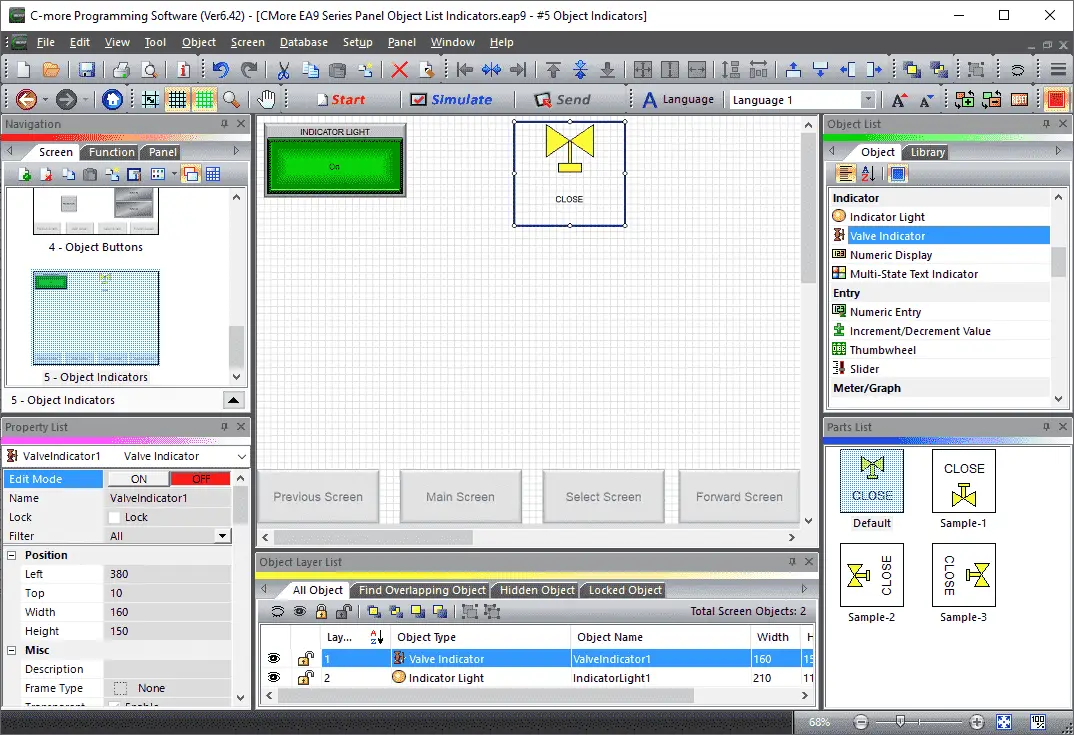

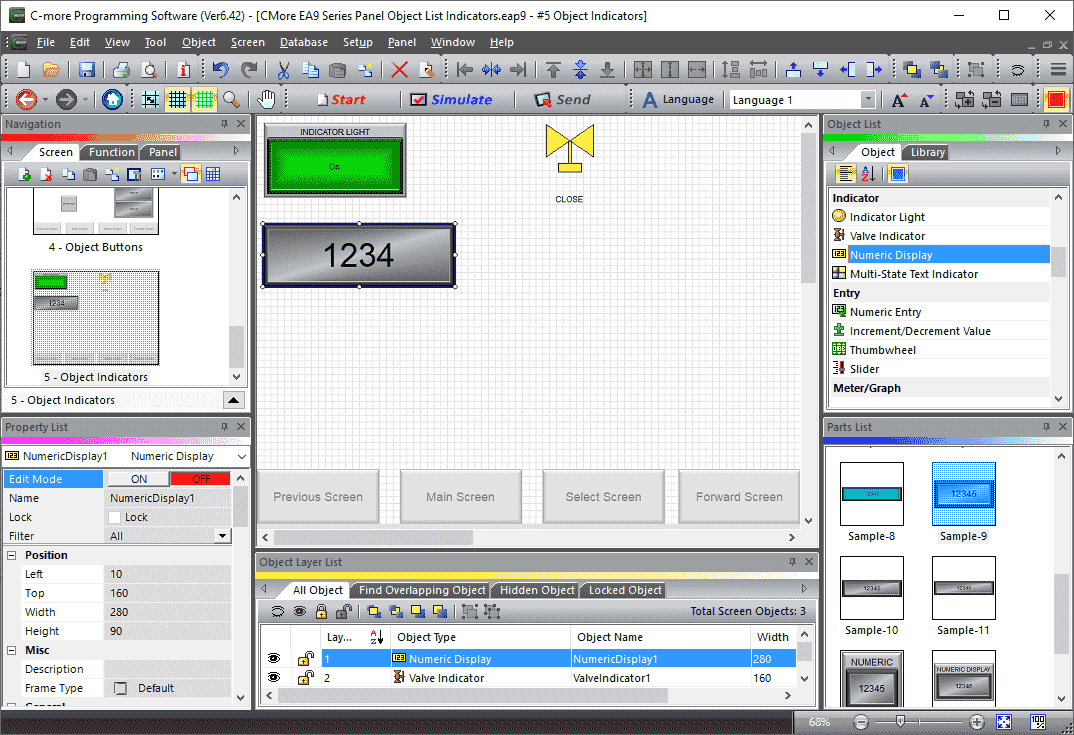

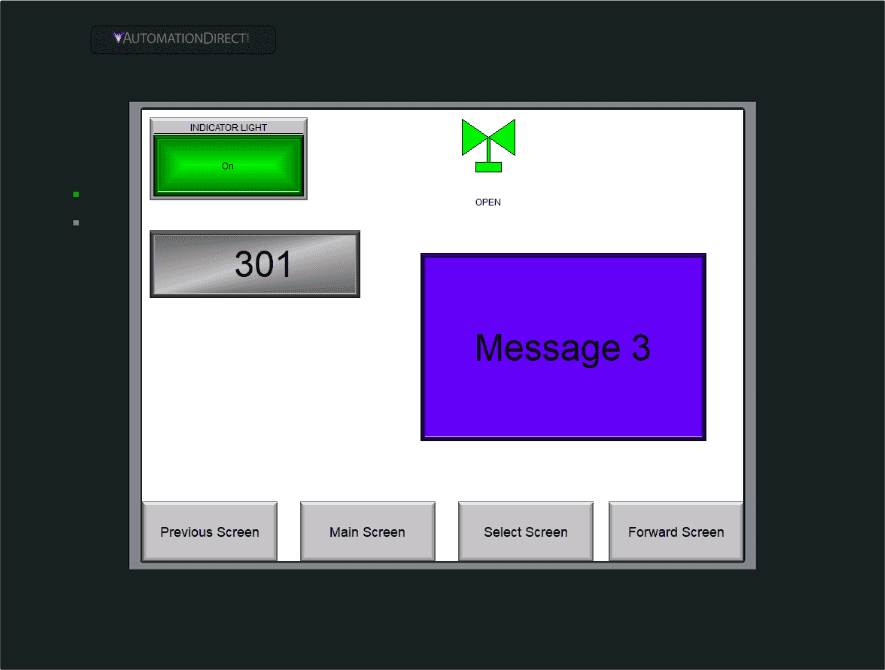

We will now look at the object indicators that we can use with our C-More HMI panel. The indicator objects that are available on the C-More EA9 are Indicator Light, Valve Indicator, Numeric Display, and Multi-State Text Indicator. Let’s get started.

Previously in this C-More EA9 HMI Panel series, we have done the following:

System Hardware

– Unboxing and Review Video

– Powering the Unit Video

Installing the Software – Video

System Setup Screens – Video

First Program

– Establishing Communication and Updating Firmware Video

– First Program Video

Panel to PLC and PLC to Panel Settings – Video

Common Screen Menu – Video

Simulate Project – Video

Object List Shapes – Video

Object List Buttons – Video

Watch the video below to see the Object Indicators in action on our C-More EA9 HMI Panel.

Setting Our C-More Object Indicators Page

We will be adding to the program we created last time. (C-More EA9 HMI Series Panel Object List Buttons).

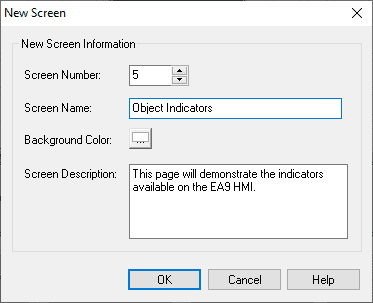

Select a new screen under the main menu | Screen | New Screen…

Alternatively, we can also use the icons in the Navigation panel.

We will name screen 5 Object Indicators. The screen description can be used to describe the screen. Hit OK.

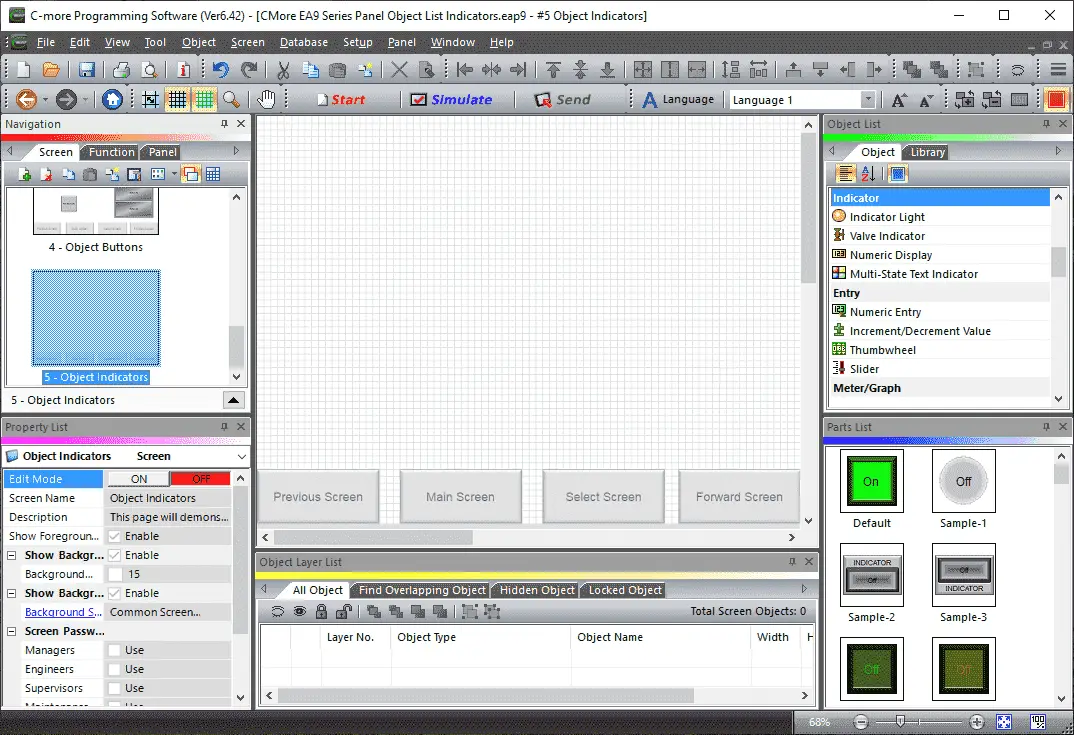

Our new screen will now be displayed.

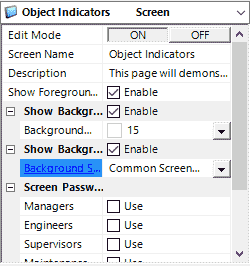

Under the property, list window turn on the editing and enable the show background. Select Common Screen Menu under the background screen. Turn off the edit mode under the property list.

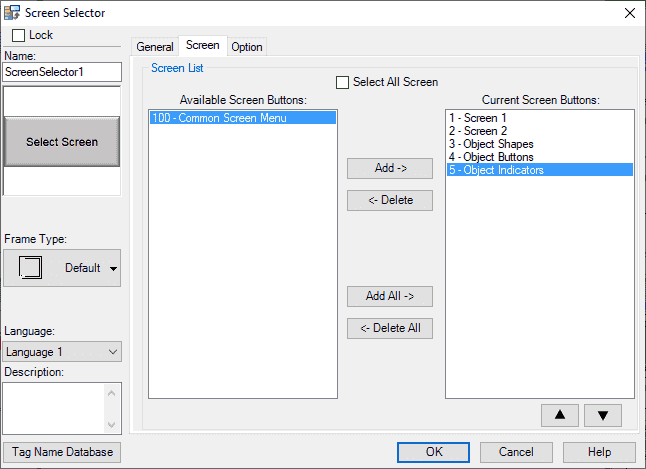

We must now add our new screen so we can select it when using the common screen menu. Select page 100. Select the Screen Selector button. Under the Screen, tab select the 5 – Object Indicators and hit the Add button so it moves it over to the Current Screen Buttons. Hit OK. We can now go back to our newly created Object Indicators screen page 5 from our navigation window.

Our new screen is now ready for us to add our indicators.

C-More Tag Name Database

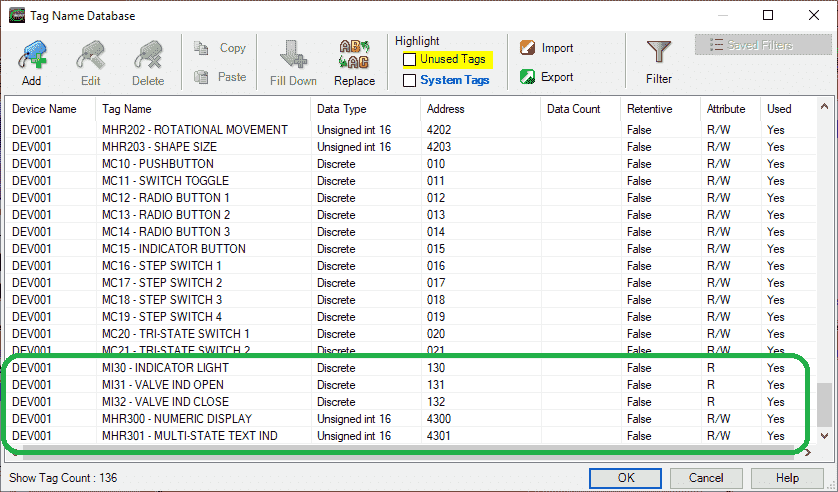

We will use the following addresses to control the button objects on the C-more HMI.

MI30 – Discrete On/Off – Modbus Address 10030 – Read (Indicator Light)

MI31 – Discrete On/Off – Modbus Address 10031 – Read (Valve Ind Open)

MI32 – Discrete On/Off – Modbus Address 10032 – Read (Valve Ind Close)

MHR300 – Unsigned Int 16 – Modbus Address 40300 – Read / Write (Numeric Display)

MHR301 – Unsigned Int 16 – Modbus Address 40301 – Read / Write (Multi-State Text Indicator)

C-More Indicators Objects

Indicator objects refer to single bits or words in the PLC that can signal an object on the C-More HMI screen. The control of these tags are done by the PLC program. Our C-More EA9 will just react to this information.

C-More Indicator Light

The indicator light object is an electronic version of a typical pushbutton indicator light normally found on control panels. This indicator light object can be assigned a tag name and used to indicate the status of bits in the PLC.

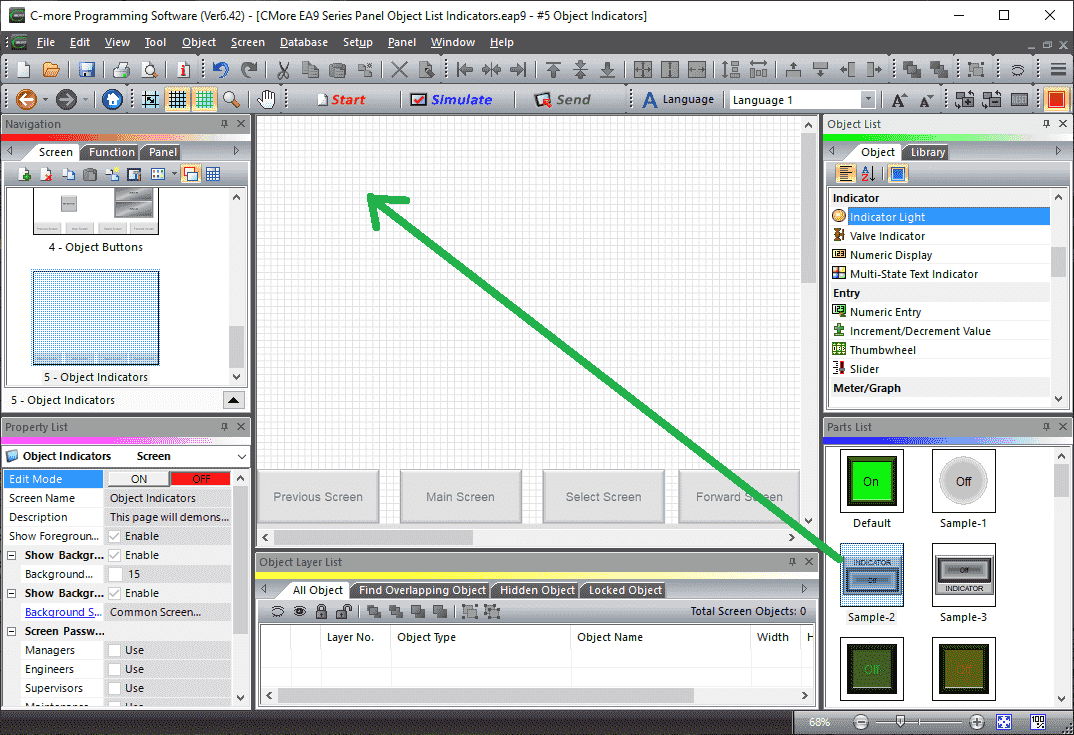

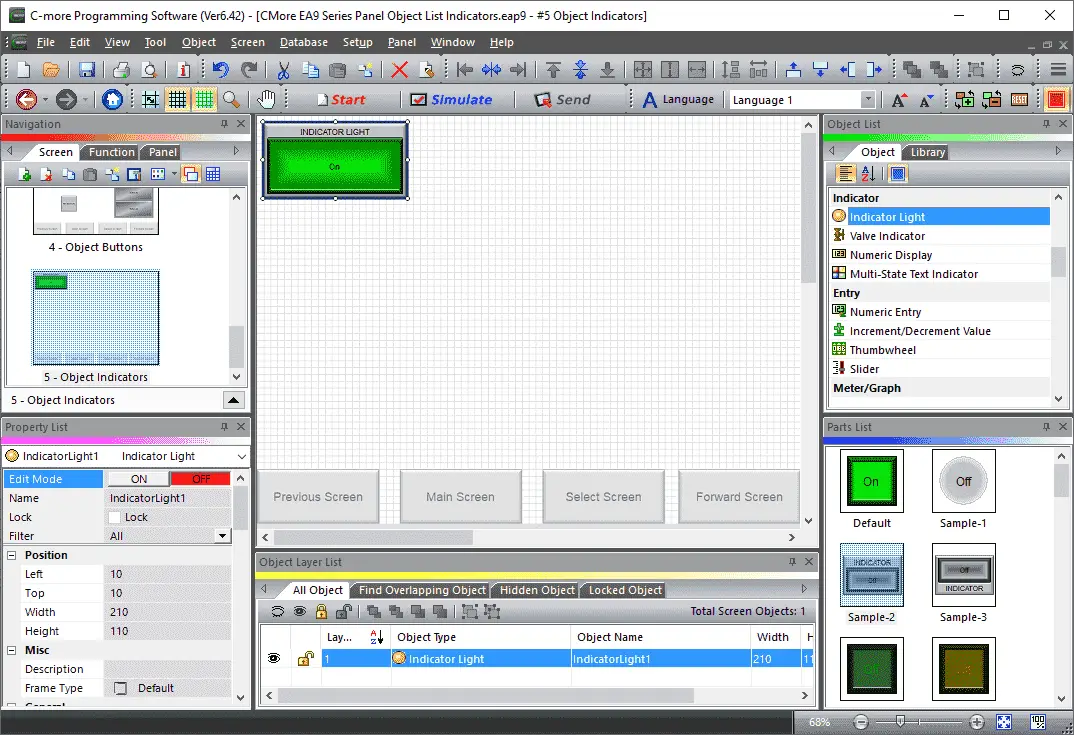

Select Screen 5 from the navigation window. We will now add an Indicator Light under the Object list window. Left click (hold) and drag the Sample-2 under the Parts List for the Indicator Light onto the screen.

Note: Choose a configured part from the Parts List window for the object selected. This will save time when configuring objects. Click and drag the item from the parts list to the screen. All of the objects will have a parts list.

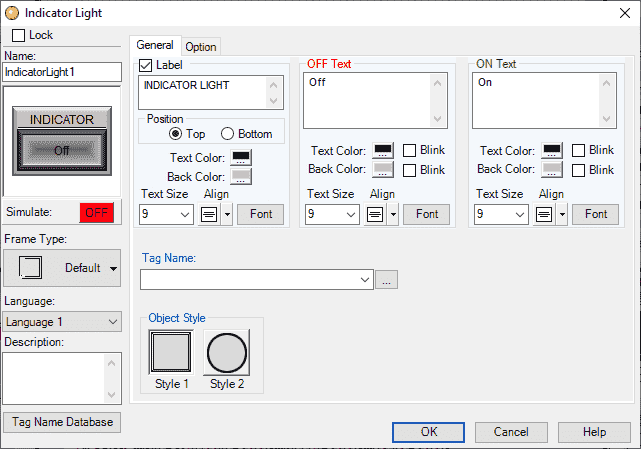

The Indicator Light screen window will display. You can also use the main menu | Object | Indicator | Indicator Light… and click on the work area of the screen. This will give you the default indicator light selection.

The following parameters can be set:

Name: This is the name of the object. The default is IndicatorLight1

Object Preview Window: This will show what the object will look like on the screen.

Simulate: This is used to test the function of the indicator light object. Click the ON or OFF box to simulate.

Frame Type: The indicator light object can be displayed in a series of frames. We will leave this as the default value.

Language: We will leave this as our default Language 1.

Description: We can enter up to 400 words to describe the purpose of the indicator light that we are programming.

Tag Name Database: This will open a window that allows you to add, edit, or delete tag names.

General Tab

Label: This will add a label to the indicator light. We will select this and leave the default name of INDICATOR LIGHT in the label text field. The position of the label will be Top and we will leave the default colour, alignment, and font.

OFF Text: This will allow us the change the text that will appear when the indicator light object is off. We will leave the default values for the text, colour, background colour, alignment, and font.

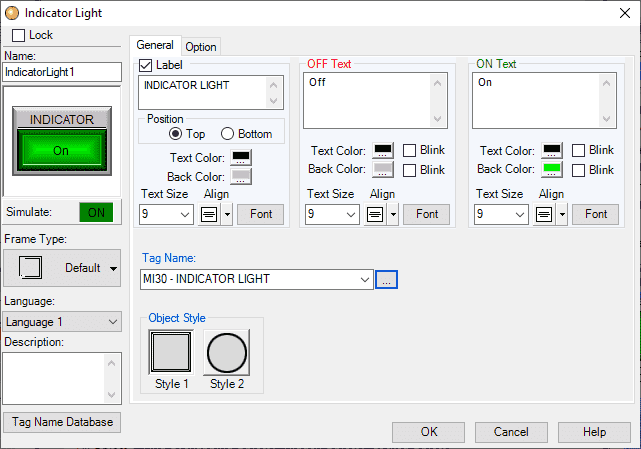

ON Text: This will allow us the change the text that will appear on the indicator light when the object is on. We will leave the default values for the text, colour, alignment, and font. Change the background colour to green so we can visibly see when this turns on.

Tag Name: This is the tag name of the PLC bit that will control the indicator lamp. The right button next to the drop-down menu will open a window that allows you to add, edit, or delete tag names. Select MI30 (Modbus Address 10030)

Note: Only the tags that can be used with the indicator light are displayed.

Object Style: You can select your preferred style. We will leave this as the default of Style 1.

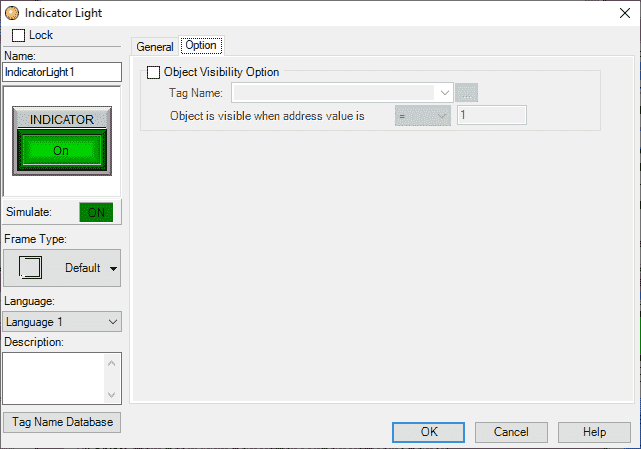

Select the options tab.

Option Tab

Object Visibility Option: We can use this selection to configure a tag to control when the object appears on the screen. C-More EA9 HMI Series Panel Object List Shapes – Video will demonstrate how we use this option.

Click OK.

We can now position and resize the indicator light object on our screen using our mouse.

C-More Valve Indicator

The valve indicator object will indicate the valve as open, closed or in transit. This is based on the assigned tags. We will now add a valve indicator to our screen.

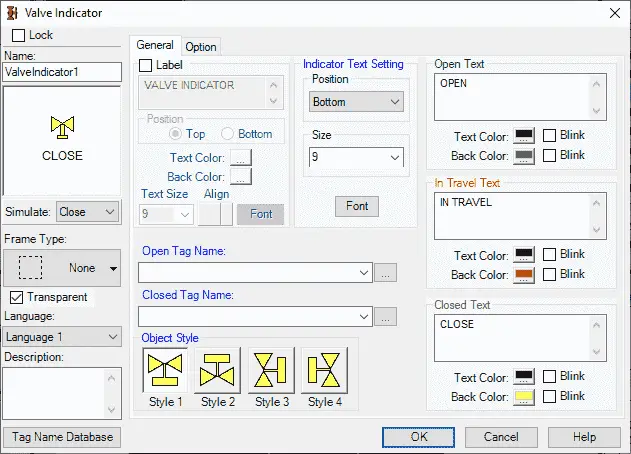

Select valve indicator from the Object List under Indicator. Now click and hold Default from the parts list and drag onto our screen.

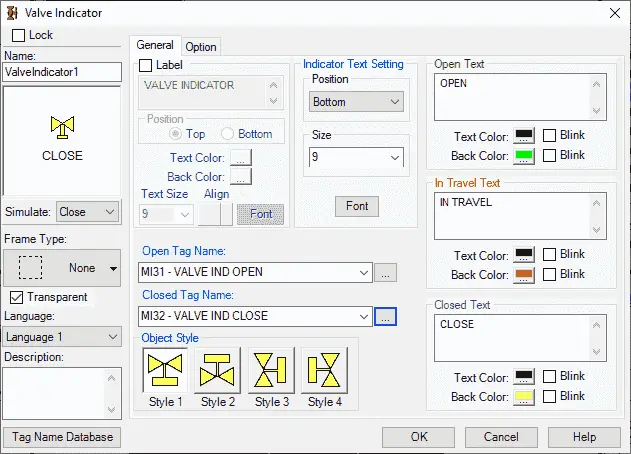

The Valve indicator window now appears. This is similar in a lot of the items that we have already programmed for the indicator light object above. The object style has many more items to choose from to suit your needs. This will depend on the orientation of the valve.

Leave the text, position, colour, background colour, alignment and font as default. Our open tag name will be MI31 (Modbus Address 10031). The close tag name will be MI32 (Modbus Address 10032). You will also notice the transparent option. This will allow the background of the object to be transparent.

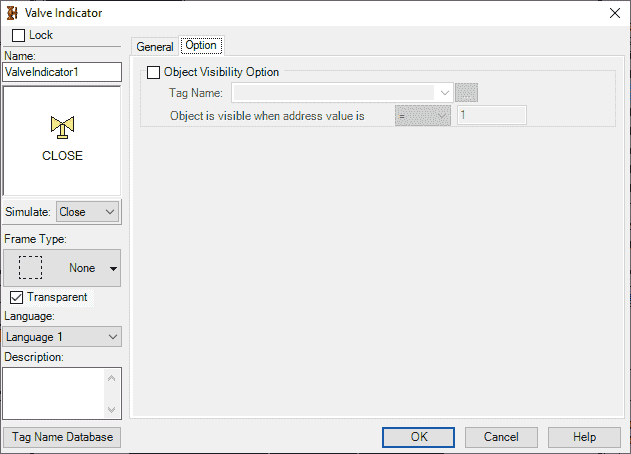

Select the options tab.

Option Tab

We can select the visibility if desired. In our case, we will not set this option.

Select OK.

We can now use the mouse and size and move our switch object.

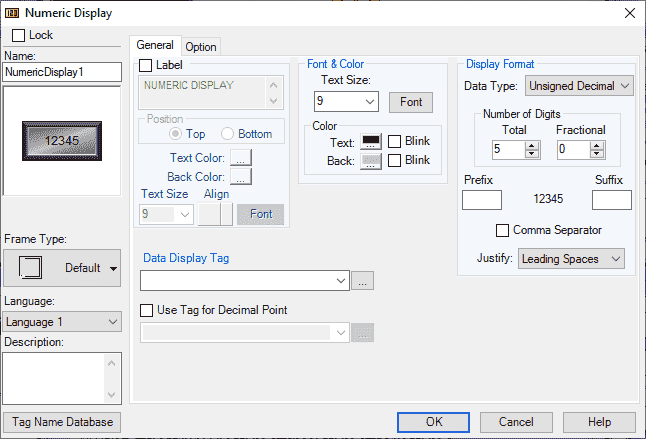

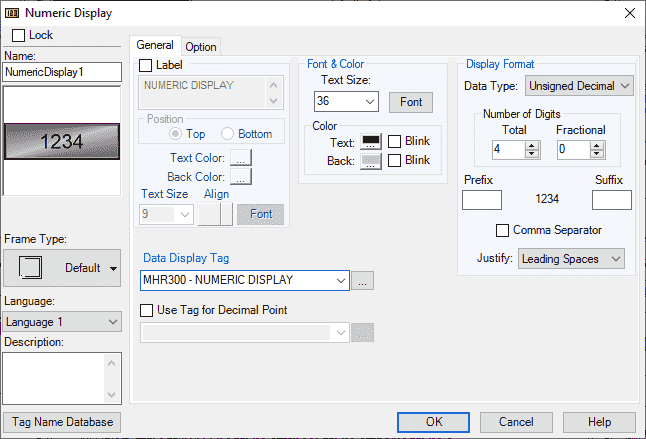

C-More Numeric Display

The numeric display object will display a value in the PLC. This can be scaled to units of measurement for easier readability.

We will now add a numeric display to our screen.

Select numeric display from the Object List under Indicator. Now click and hold Sample-9 from the parts list and drag onto our screen.

The numeric display window will now appear. These object windows will all have a similar look and feel.

We will set the font size to 36. The total number of digits will be 4. We will leave everything else as the default.

Our data display tag will be set for MHR300 (Modbus Address 40300)

Select the options tab.

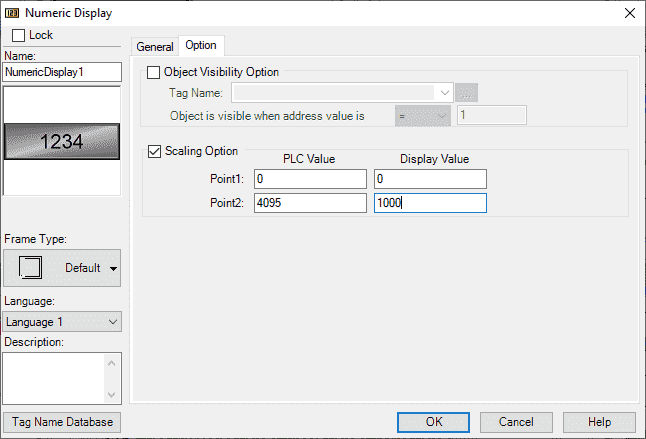

Option Tab

We will not use visibility.

The scaling option will be set for the PLC value 0 to 4095. This will represent the values 0 to 1000 respectfully on the C-More HMI screen.

Select OK

We can now use the mouse and size and move our numeric display object.

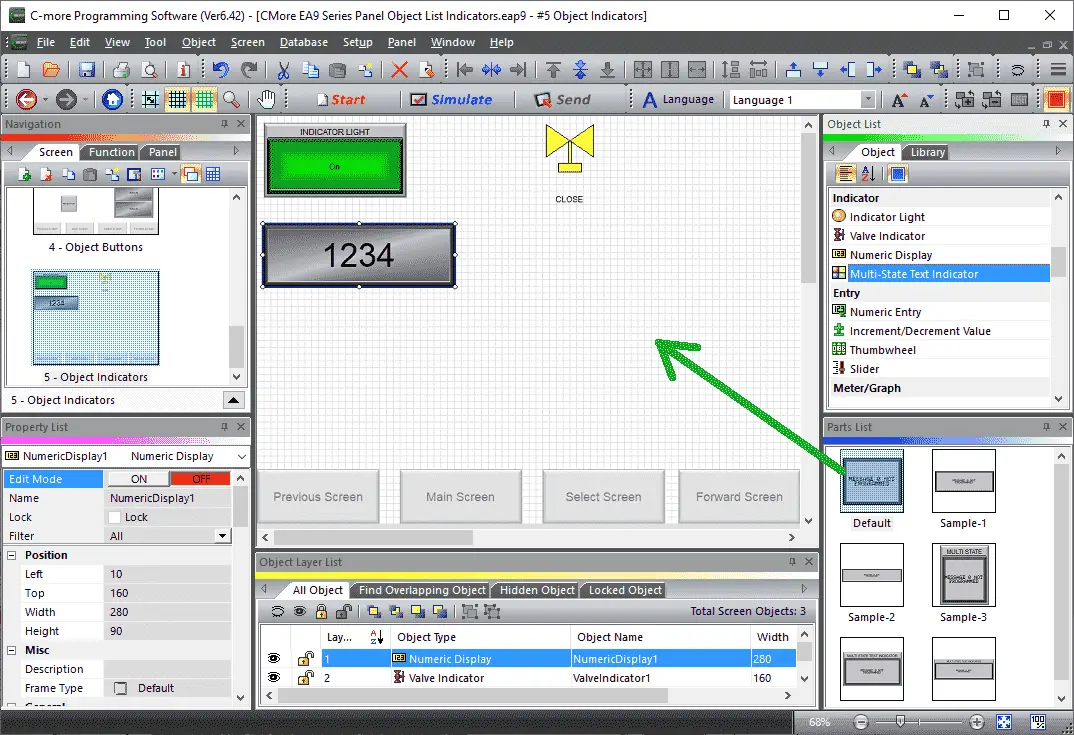

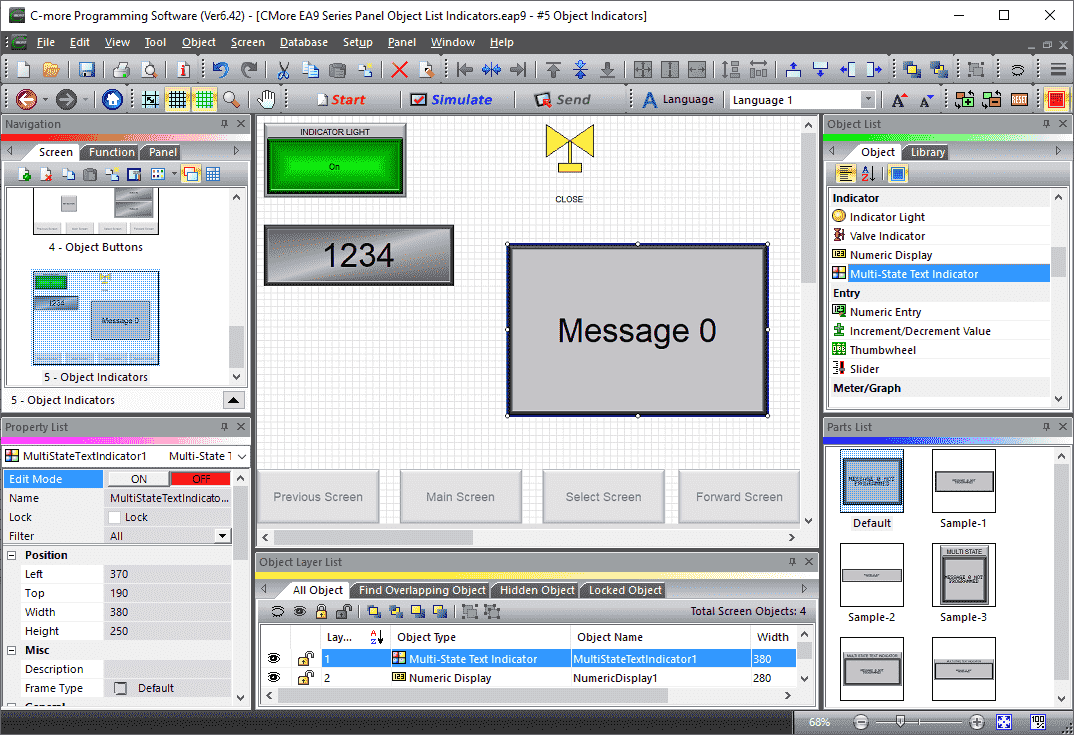

C-More Multi-State Text Indicators

The multi-state text indicator will display different programmed text messages based on information in a word within the PLC. Let’s add a multi-state text indicator to our screen.

Select multi-state text indicator from the Object List under Indicator. Now click and hold Default from the parts list and drag onto our screen.

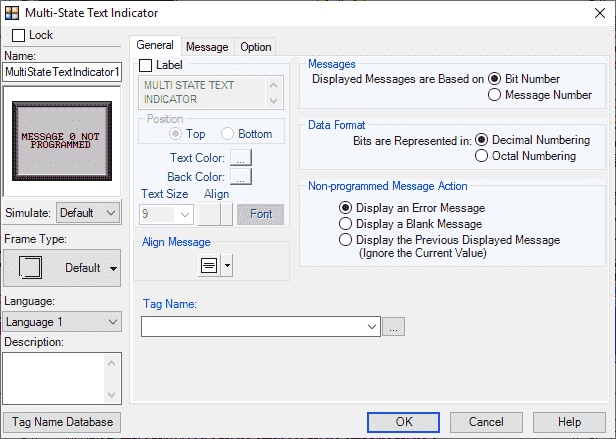

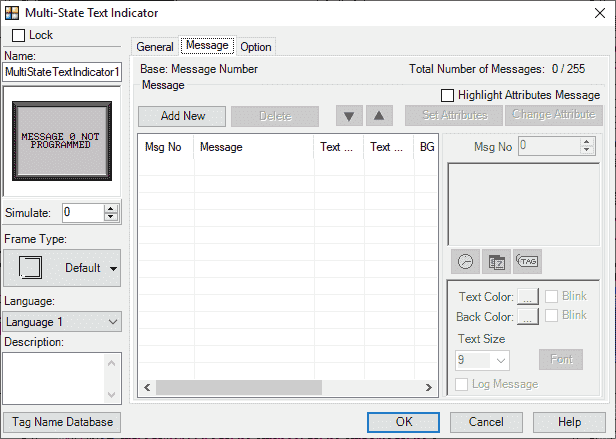

The multi-state text indicator window will now appear.

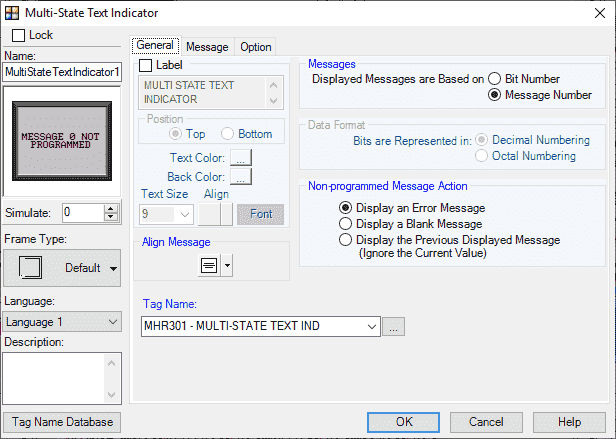

We will leave most of the settings on default. Under the messages, select displayed messages are based on message number.

We will set the Tag Name to MHR301. (Modbus Address 040301). Select the message tab.

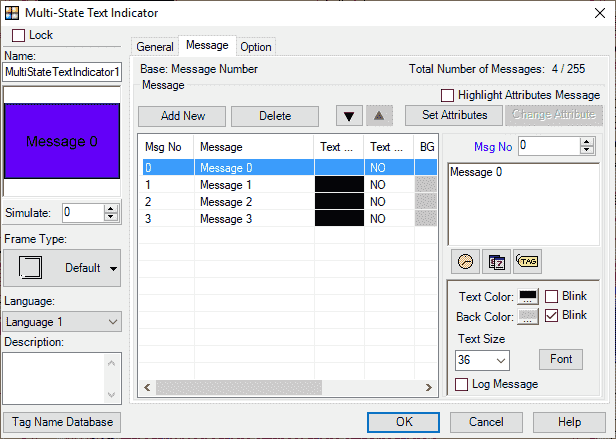

Message Tab

This is where we will write our messages based upon the value in the PLC memory word. (MHR301)

Enter message 0 to 3. You will notice that we can change the font size and colour for each of the messages. You can also blink the text or background. Select the options tab.

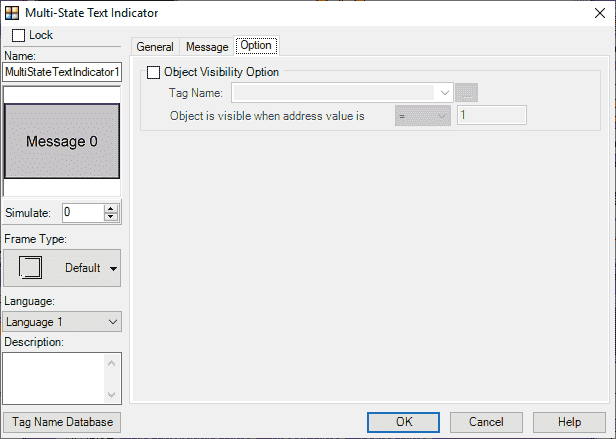

Option Tab

We can select the visibility.

Select OK.

We can now use the mouse and size and move our multi-state text indicator object.

Simulate our C-More Indicators Project

We can use the simulator to view and try our object indicators. This will ensure the visual and bit operation that we want in our program.

PLC Program Additions – C-More Indicators

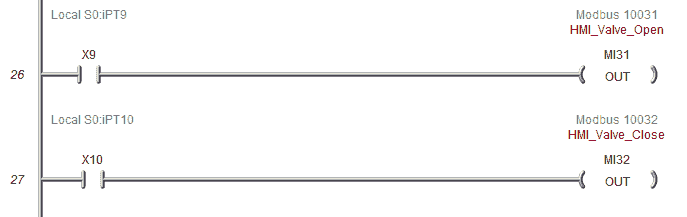

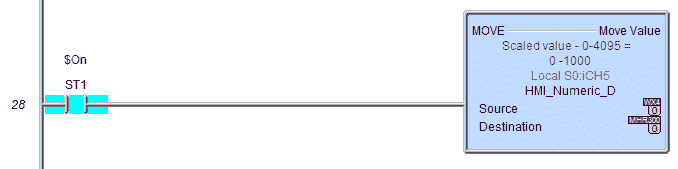

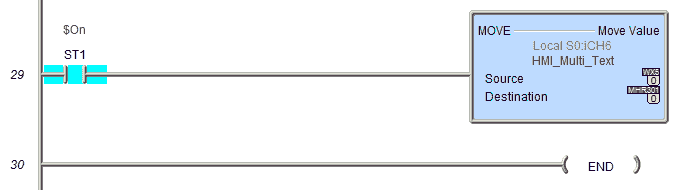

Using the program we previously developed, we will add additional rungs to control the indicator objects that we have just created.

When input X8 turns on MI30 (Modbus 10030) will turn on.

X9 will indicate that the Valve Indicator Open is active. X10 will indicate that the Valve Indicator Close is active. If both or neither of these inputs are on/off then the valve will indicate it is in transit.

Here is our numeric display. We have scaled the input in the C-More HMI so that when the input goes from 0 to 4095, the display will show 0 to 1000.

WX5 will indicate what message will be displayed on our C-More HMI. This is using the Multi-State Text Indicator. In our case, we are using the message number in the word as opposed to the bit in the word.

Download the PLC and C-More program here.

Watch the video below to see the Object Indicators in action on our C-More EA9 HMI Panel. This will also demonstrate the PLC ladder code for functionality.

C-More EA9 Panels from Automation Direct

https://www.automationdirect.com/c-more/home

C-More – Graphic Panel (EA9 Series) User Manual and Quick Start Guides

https://cdn.automationdirect.com/static/manuals/ea9userm/ea9userm.html

EA9-T10CL C-More Specifications

https://cdn.automationdirect.com/static/specs/ea9t10cl.pdf

C-More EA9 Programming Software (Current Version V6.42)

https://support.automationdirect.com/products/cmore.html

This software will enable you to program all of the C-More EA9 HMI units. It includes a simulator for your application.

Next time we will look more at the object list information entry that we can use in the C-More HMI Panel.

Watch on YouTube: C-More EA9 HMI Series Panel Object List Indicators

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.