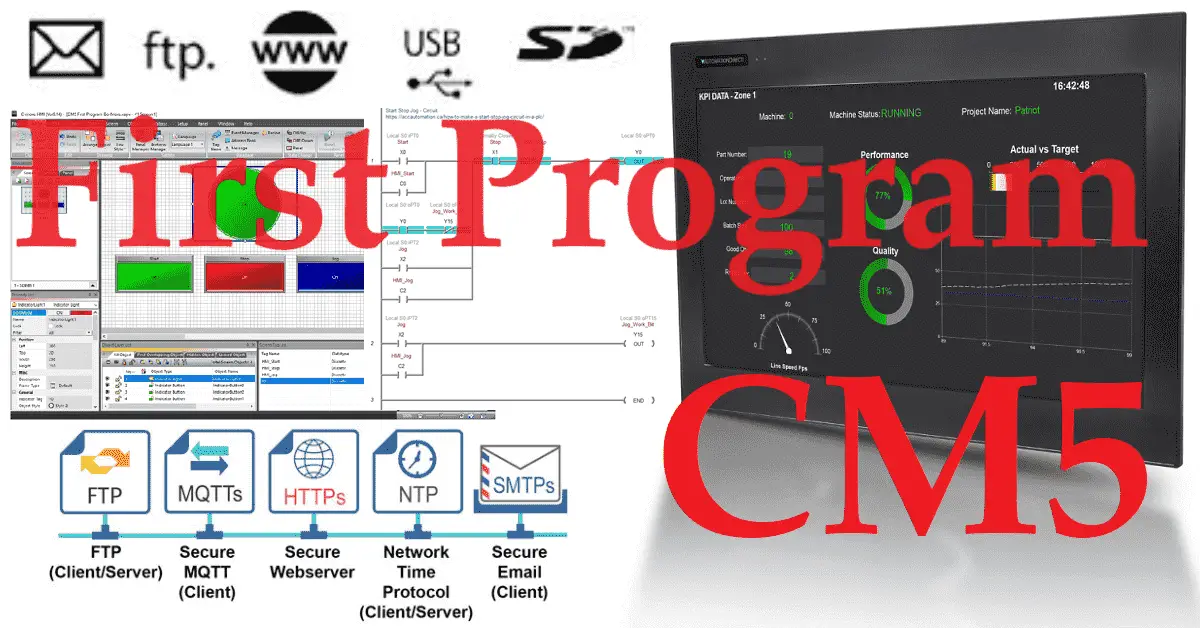

First Program C-More CM5 Series HMI

Programming a C-more CM5 HMI (Human-Machine Interface) or any other unit can initially seem daunting, but it can be a rewarding experience with the proper guidance. This post will walk you through the steps to program a C-more HMI unit, specifically the CM5 HMI model. Whether you’re a beginner or have some experience with HMI … Read more