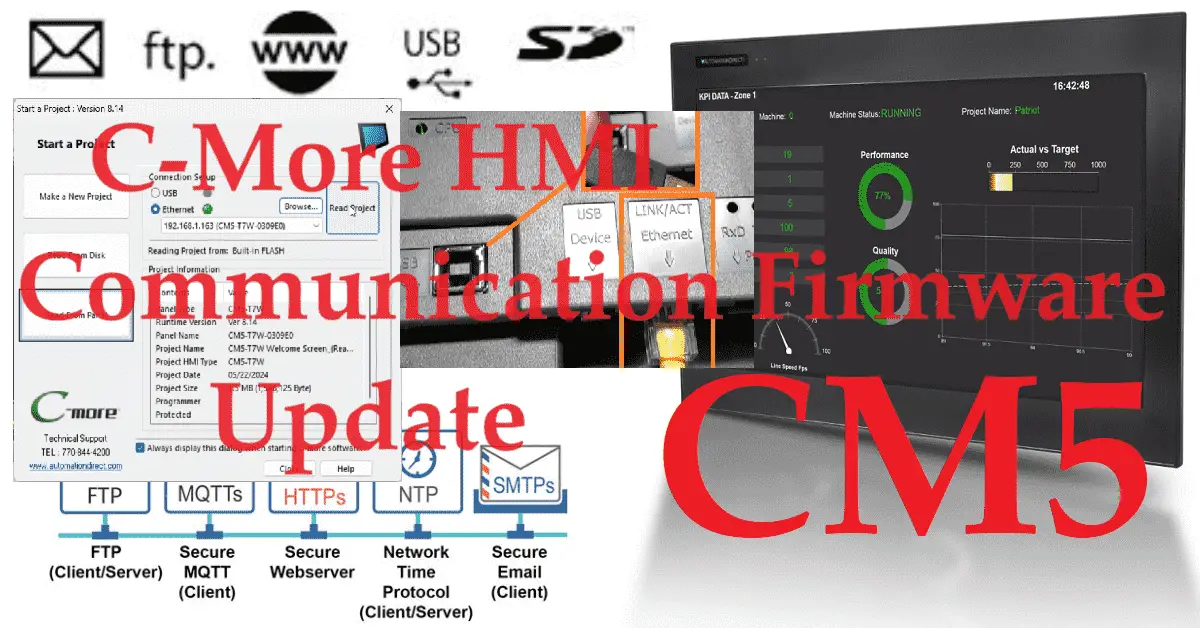

C-More CM5 HMI Communication Firmware Update

We will establish communication and check the firmware on our C-More CM5 HMI touch panel. Communication with our CM5 HMI can be done via USB or Ethernet. The C-More CM5 has a USB port just used for programming, which is especially helpful if you are physically connecting to the HMI unit. Firmware is a type … Read more