We will now look at the tag numbering systems used with the Productivity controller. The Productivity Suite Software allows us to use tags in the PLC. Tags are a method for assigning and referencing memory locations (numbering systems) within the programmable logic controller. They allow a more structured programming approach and are stored within a tag database. The tag database is stored in the memory of the Productivity Series of PLCs from Automation Direct. Do not overthink tags. Tags are just names that we assign to variables (numbering systems) of any data type stored in the PLC memory.

We will be looking at data types available in the Productivity PLC and how to use the tag database. Let’s get started.

Previously in this Productivity 1000 series PLC, we have discussed:

System Hardware – Video

Installing the Software – Video

Establishing Communication – Video

First Program – Video

Documenting the Program – Video

Monitoring and Testing the Program – Video

Online Editing and Debug Mode – Video

Data Types – Productivity Numbering Systems

There are multiple data types available for configuring parameters and tags within your automation project. Here is a list of the available types:

– Boolean – True or False, 1 or 0, on or off. These are used for discrete I/O point tag names as well as internal tag names used for logic control.

– Integer, 8 Bit Unsigned – These whole or natural numbers range from 0 to 255. (0 to FF hexadecimal) They are used for numerical tags when only positive variables will be used within a byte boundary.

– Integer, 16 Bit Signed – Range is -32768 to 32767. These are used for numerical tags where variables have the potential for negative or positive values.

– Integer, 16 Bit Unsigned – Range is 0 to 65535. These are used for tags that will only have a positive value.

– Integer, 16 Bit BCD. Unsigned binary coded decimal will have the range of 0 to 9999. These will be used for tags that can only be represented by the decimal numbering system. 0-9 for each digit.

– Integer, 32 Bit Signed – Range is -2,147,483,648 to 2,147,483,647. This is used as the default for most numeric tags that have the potential for both negative and positive values.

– Integer, 32 Bit BCD. Unsigned binary coded decimal will have the range of 0 to 99,999,999. These will be used for tags that can only be represented by the decimal numbering system. 0-9 for each digit.

– Float, 32 Bit. This uses the IEEE format floating-point number ranging from -3.39×1038 to 3.39×1038. This data type is for tags that need to be reading in this format.

– String. ASCII or test representation which allocates one byte (8 bits) per character. These are used for tags that are words when using instructions like ASCII, email, and LCD.

– Constant. This is a fixed value for a numeric or Boolean tag name. Constants can be integers, floating-point or strings. When you enter the constant, the field defined by the data entered assumes the range.

Ex. 1 = 32 bit signed integer, 1.0 = floating point, A = string

What everybody ought to know about PLC (Programmable Logic Controller) numbering systems is a post that will explain further the meaning behind the above types of numbers.

https://accautomation.ca/what-everybody-ought-to-know-about-plc-programmable-logic-controller-numbering-systems/

Tag Database – Productivity Numbering Systems

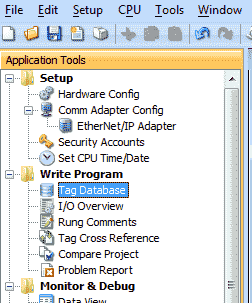

Open the tag database by clicking on the Tag Database under the Write Program heading in the Application Tools.

You can also use the main menu | Edit | Tag Database to access the tag database.

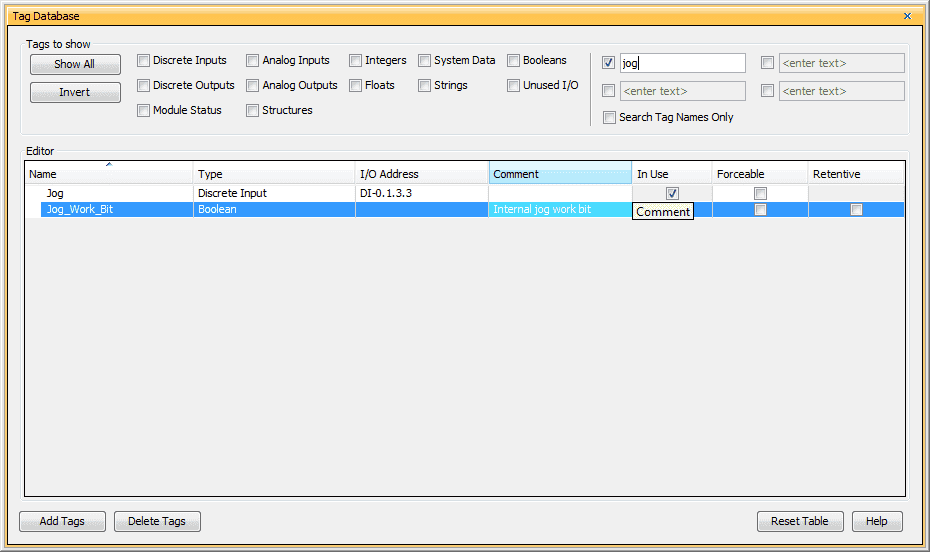

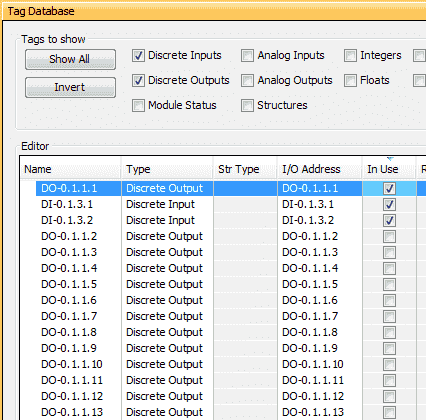

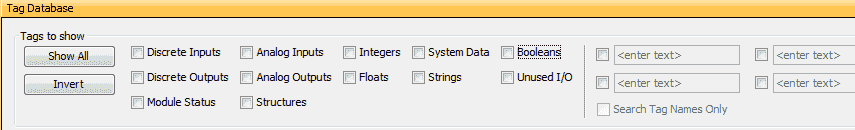

Tags to Show – Productivity Numbering Systems

This upper part of the Tag Database window will help you to find the tags and information that you require quickly.

Show All – This will show all of the tags

Invert – This will invert all of the selected tag types. If the input type like Discrete Inputs is checked and you hit the invert button, the tag will be unchecked. If the input type is unchecked and you invert then it will be checked.

The tags will allow you to search the database for a particular name or phase.

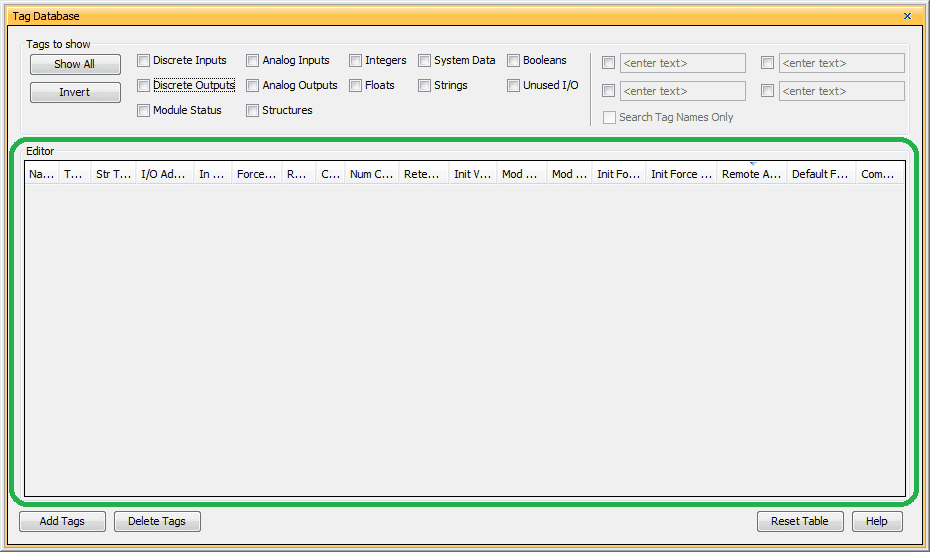

Editor – Productivity Numbering Systems

The editor has the following columns of information.

Name – Name was given to the applicable tag

Type – Data type used by the tag

Str Type – Indicates the type of structure used

System ID – Internal ID assigned to user-defined tags

I/O Address – The respective assigned I/O address

Rows – The number of rows applicable to a 2D Array Data type

Cols – The number of columns applicable to a 1D or 2D Array Data type

Num Chars – The number of Characters applicable to a String Data type

Retentive – Checkbox indicating if the tag is retentive. If power is lost or removed from the PLC this determines if the information in the tag is retained or not.

Init Value – Value entered in this field will be used for the initial value

Wire Label – Use this field to indicate the wire label information for the I/O point

Mod Start – Optional Modbus Starting Address – We specify what information can be shared on the network through Modbus.

Mod End – Optional Modbus Ending Address

Forceable – Allows the tag to be forced using Data View. A maximum of 64 tags may be selected as forceable at any given time.

Init Forced – Allows the tag to be forced upon start-up from a power cycle or stop/run transition

Init Forced Value – Value entered in this field will be used for the tag’s value upon an initial force.

Comment – Use this field to add Comments associated with the tag.

Remote Access – Checkbox that indicates the tag can be monitored remotely via the CPU Data Remote Monitor App.

Default Format – Used with integers. Allows data to be viewed in various formats, i.e. decimal, hex, etc.

In Use – Checkbox indicates the tag is used in the ladder diagram.

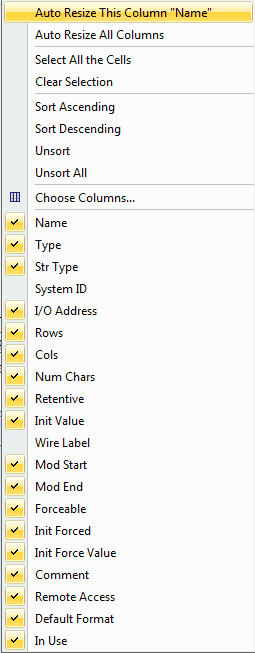

Right-clicking on the column name will bring up this menu. You can auto resize the columns, select, sort, hide or show columns.

Note: Select and drag the column to another location to arrange the tags the way you want to see them. You can also resize the width of the column by clicking in between and dragging the width. See the video below.

![]()

Add Tags – We can add tags of any data type. Tags can be made individually or grouped together in arrays. We will be discussing arrays and functions later in this series.

Delete Tags – Remove a tag from the tag database.

Reset Table – Restore the table to original default settings.

Help – Explore the help menu for Tag Database

The tag database allows you to manipulate and view all of the system and personal tags that you have developed. Watch the video below to see the numbering systems and tag database in our Productivity 1000 Series PLC.

Productivity 1000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Programming Software (Free Download Link)

This software contains all of the instruction sets and help files for the Productivity Series.

Next time we will look at contact and coil instructions in the Productivity 1000 Series PLC.

Watch on YouTube: Productivity 1000 Series PLC – Numbering Systems and Tag Database

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.