If you are looking to purchase a PLC system, there are three key components that you should look for. If your current system does not contain these features, you need to replace it with one that does as soon as possible. The three most important features you should look for in your new PLC system are the open communications protocol, the ability to integrate easily with other methods, and the ability to have remote access. Without these three essential requirements, your PLC system will be far less effective and will be more expensive to operate than it needs to be.

We are all data companies that need the information for continued improvement. The industrial internet of things (IIoT) is essential, and the ability to take advantage of this starts with the hardware you specify for your PLC control. PLCs are now considered edge devices. This means that information should be able to be sent and received to the PLC controller when it is required.

We are all data companies that need the information for continued improvement. The industrial internet of things (IIoT) is essential, and the ability to take advantage of this starts with the hardware you specify for your PLC control. PLCs are now considered edge devices. This means that information should be able to be sent and received to the PLC controller when it is required.

PLC Capabilities (Expansion)

Along with some expansion capabilities, a plc should be capable of handling a higher-input and output counts than traditional devices. Given the tendency of new high-tech devices to already have programmable logic controllers integrated into them, the plc should be able to support input and output counts greater than conventional machines. To avoid purchasing redundant expansion cards and hardware, buy a programmable logic controller that supports a sufficient number of input and output points at the start. This prolongs the life of the PLC and saves you, the user, money over time.

The speed and size of PLC systems no longer match the old saying of “the larger the IO, the slower the scan time.” How fast do you need to be? Modern PLCs have multiple CPUs (central processing units) to handle various tasks, so the speed is no longer an issue.

The speed and size of PLC systems no longer match the old saying of “the larger the IO, the slower the scan time.” How fast do you need to be? Modern PLCs have multiple CPUs (central processing units) to handle various tasks, so the speed is no longer an issue.

PLC capabilities beyond just the physical input and outputs (IO). Many new features of programmable logic controllers require firmware (PLC operating software) to keep them current. Look for a manufacturer or distributor supporting the hardware and software through updates. How long has it been since your manufacturer updated and improved your system?

PLC Communication Protocols

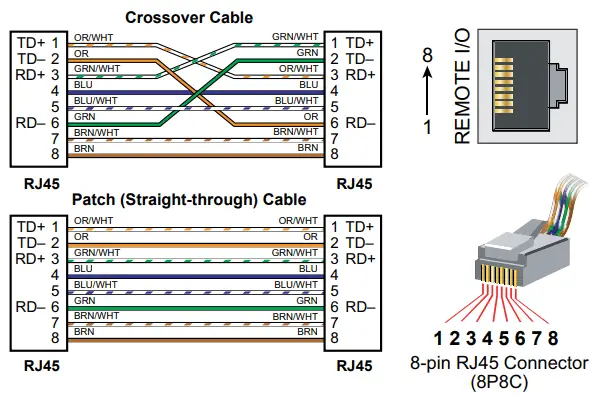

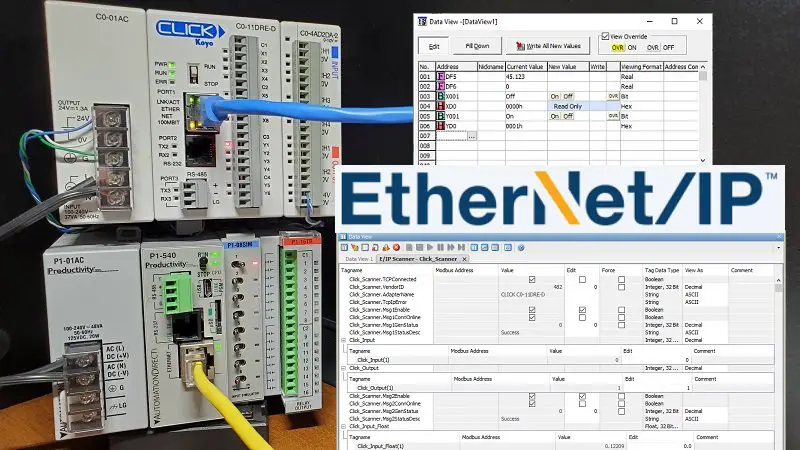

Communication protocols are necessary for the success of a PLC, and you’ll want to know if your controller supports standard industrial protocols like Modbus or Ethernet/IP. Dedicated protocols in the PLC will limit your connectivity to additional sensors, systems, and devices.

Investing in an Internet-connected system and don’t know what kind of protocol you need? A safe bet is Modbus/TCP–it’s tried and true, pretty reliable, and can be updated over time as needed.

Investing in an Internet-connected system and don’t know what kind of protocol you need? A safe bet is Modbus/TCP–it’s tried and true, pretty reliable, and can be updated over time as needed.

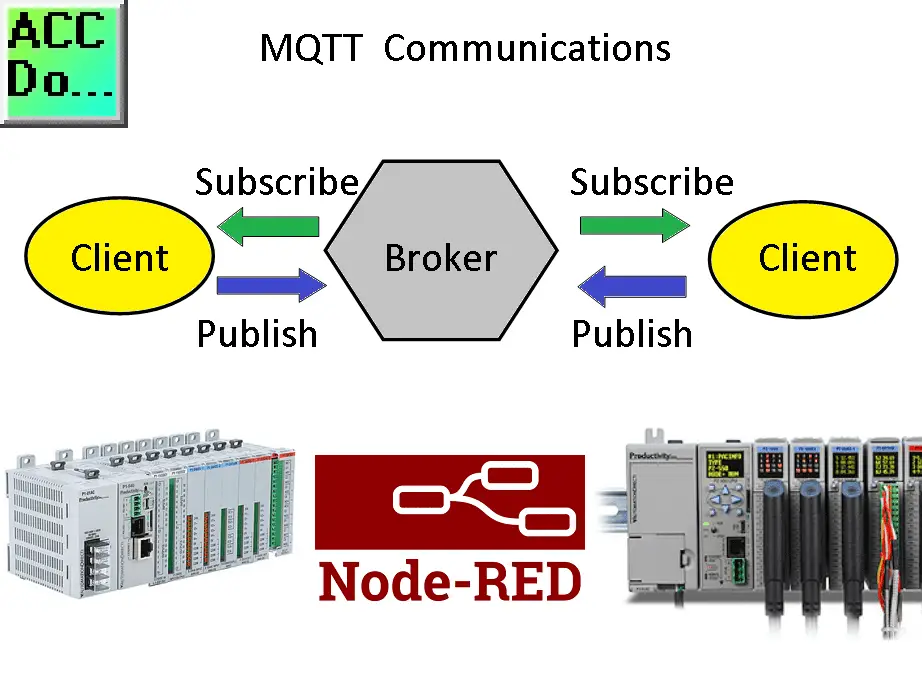

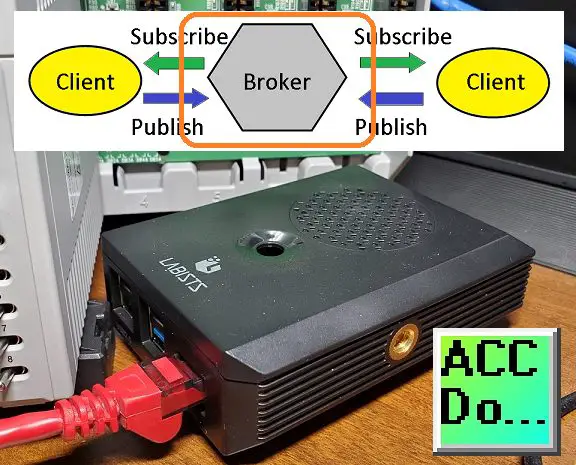

Current protocols in demand are MQTT, an IoT protocol. In short, it’s used as the internet of things hub protocol for publishing and subscribing.

Current protocols in demand are MQTT, an IoT protocol. In short, it’s used as the internet of things hub protocol for publishing and subscribing.

Using an MQTT broker, this protocol can incorporate a unified namespace for the overall business. The PLC will be the MQTT client that will publish and subscribe data to the namespace of the company.

Using an MQTT broker, this protocol can incorporate a unified namespace for the overall business. The PLC will be the MQTT client that will publish and subscribe data to the namespace of the company.

Communication is also required for HMI (human-machine interface). The protocol used and connection method will vary with different HMI manufacturers. Still, they will generally have the most common PLC manufacturer protocol drivers and some of the standard industrial protocols.

Communication is also required for HMI (human-machine interface). The protocol used and connection method will vary with different HMI manufacturers. Still, they will generally have the most common PLC manufacturer protocol drivers and some of the standard industrial protocols.

PLC Programming Software

Ladder logic is the most common programming language for programmable logic controllers. The programming software for the PLC may end up costing you more than the hardware itself after the purchase and annual maintenance fees. The hardware is meant to last for decades of industrial use without the need to program the controller after the initial integration.

PLC programming software should be free. However, free software sometimes has limitations and costs more than it should. In the end, consider that most programming languages are either free or inexpensive —which means you don’t have to spend money on something that won’t help you in the long run. Ensure you know what you get before purchasing or investing time in PLC programming software.

PLC programming software should be free. However, free software sometimes has limitations and costs more than it should. In the end, consider that most programming languages are either free or inexpensive —which means you don’t have to spend money on something that won’t help you in the long run. Ensure you know what you get before purchasing or investing time in PLC programming software.

Testing your PLC programming software before any money / annual fees are charged is critical in determining what is best for your environment. Many manufacturers will have a free limited download of the programming software. Some will even have completely free no, limited programming software. This determines how the PLC manufacturer goes to market and how they expect to make their money. If you have to pay a fee, I would suggest contacting the manufacturer and distributors of the product. They will often loan you a copy of the PLC programming software to evaluate.

Testing your PLC programming software before any money / annual fees are charged is critical in determining what is best for your environment. Many manufacturers will have a free limited download of the programming software. Some will even have completely free no, limited programming software. This determines how the PLC manufacturer goes to market and how they expect to make their money. If you have to pay a fee, I would suggest contacting the manufacturer and distributors of the product. They will often loan you a copy of the PLC programming software to evaluate.

What PLC Should I Buy?

Some of the most popular controllers for industrial automation applications are Allen-Bradley (Rockwell Automation), Siemens, Mitsubishi, Omron, Automation Direct, and GE Fanuc. You should first make sure that the controller you’re considering supports the items listed above. If it doesn’t, don’t bother shopping further — there are too many other good options to spend time on a system that isn’t capable of doing what you need.

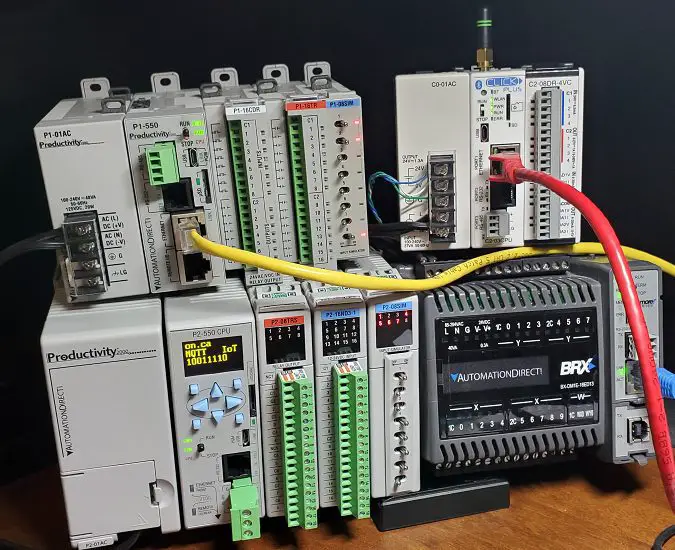

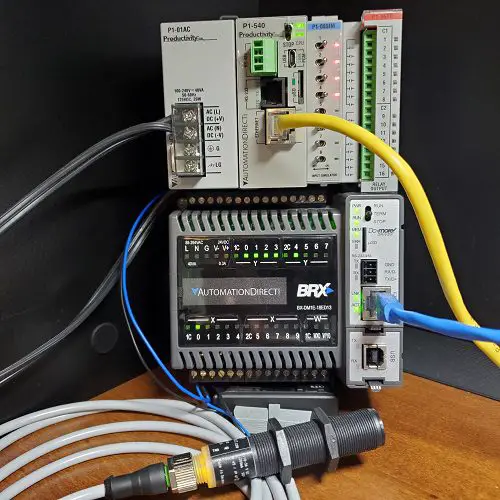

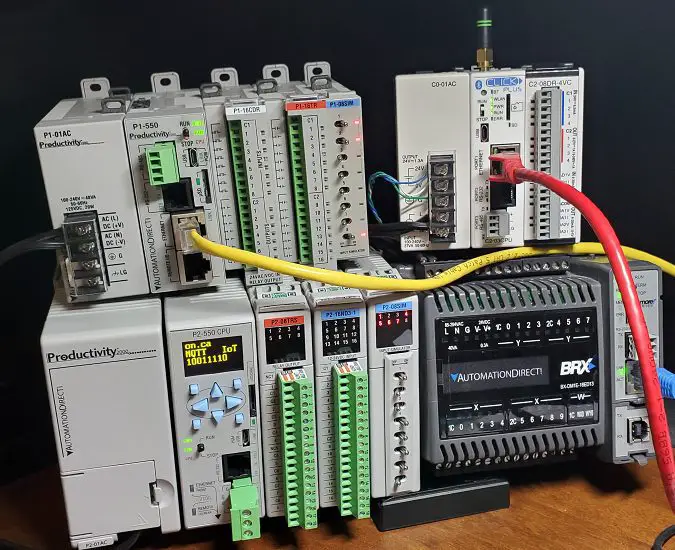

This site (ACC Automation) has a few different PLC manufacturers that I believe give the best value for the investment. Automation Direct with the Koyo (Click), Do-More, and Productivity Family of PLC controllers put the above items in their products for you. They sell and support PLC hardware directly to you without the markup from distribution. Programming software is often free because of its marketing.

Support is sometimes overlooked. I would strongly suggest calling the manufacturer or distributor and trying out their technical support. This is a relationship built with the PLC manufacturer and agents.

The choice is up to you on the PLC to purchase and invest. It would be best to be realistic about how much time you have to learn new systems and train others in your company to use them.

The choice is up to you on the PLC to purchase and invest. It would be best to be realistic about how much time you have to learn new systems and train others in your company to use them.

The future is now. Communication, expandability, and access are vital in data collection. Your PLC edge devices should fit within your plans.

The future is now. Communication, expandability, and access are vital in data collection. Your PLC edge devices should fit within your plans.

Learning and training series for PLCs that have the above requirements.

Click / Click PLUS (Koyo)

BRX Do-More

Productivity Series

P1000

P2000

C-More EA9 Series of HMI

(Webserver, FTP, Data Logging, Free Remote Apps, etc.)

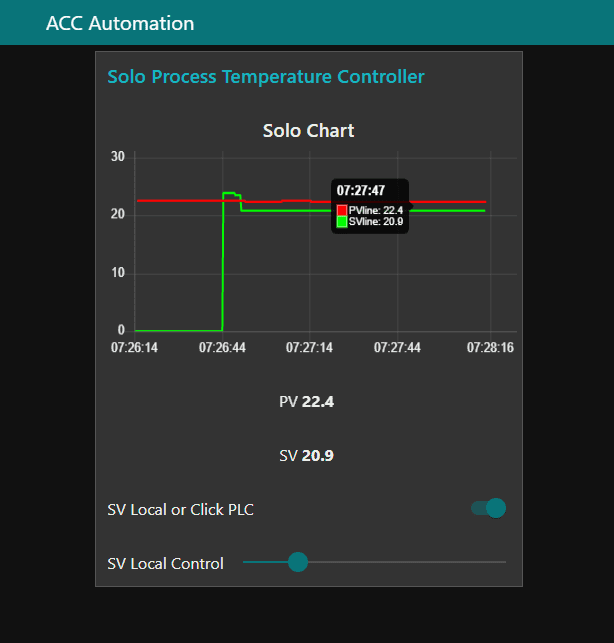

Node-Red is a free IoT software hub that can communicate MQTT and many standard industrial protocols. This series will help you communicate to the PLC, create an HMI on any electronic device, log data to a database, and view the information on a spreadsheet for analysis.

Node-RED IoT enabling Software

Watch on YouTube: Don’t Get Caught Without These 3 PLC Requirements

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII, and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.