A human-machine interface (HMI) is present in some form for every PLC. The HMI connects a user to a machine system to exchange information or control data. This interaction with the system can be through hardware or software.

HMIs offer different people information and control in many ways for the automated system. Operators, supervisors, mechanics, electricians, engineers, and programmers all have different needs. The machine HMI(s) must provide or make the information easy for all the people who use the system.

HMIs offer different people information and control in many ways for the automated system. Operators, supervisors, mechanics, electricians, engineers, and programmers all have different needs. The machine HMI(s) must provide or make the information easy for all the people who use the system.

We will now look at some of the ways that human-machine interfaces (HMI) are used in automated systems today. Let’s get started.

Previously in this PLC Learning Series:

PLC Training Series – Tutorial for Everyone – Video

What are PLC Inputs? – Video

What are PLC Outputs? – Video

Memory Backup – Video

Understanding Numbers – Video

Program Cyclic Scan – Video

Programming Steps – Video

Watch the video below to see what is meant when we say HMI and edge PLC.

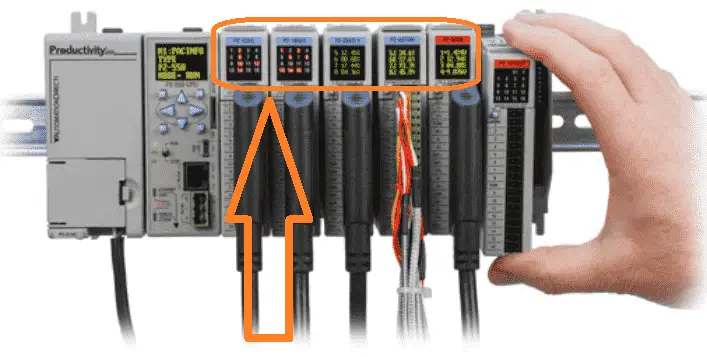

PLC Controller Inputs and Outputs Indicators (LED/OLED)

Programmers and maintenance personal will use the light-emitting diodes (LED) on the input and output cards of the PLC.

A discrete input LED on a PLC input card indicates that a signal is being received. The connected input can be switched on/off to determine if the wiring, sensor, and PLC input are functioning correctly.

A discrete input LED on a PLC input card indicates that a signal is being received. The connected input can be switched on/off to determine if the wiring, sensor, and PLC input are functioning correctly.

An LED on the discrete PLC output card indicates that the output is being turned on. If the actual output is not operating then the wiring, output device or PLC output can be checked.

Analog inputs and outputs will have the output voltage or range displayed. This is good troubleshooting information without having to use external meters to measure.

The PLC CPU also offers information to the user. The operation mode and other information are usually displayed. Some PLCs will also offer the ability of the program to display custom messages for the automated control system.

The PLC CPU also offers information to the user. The operation mode and other information are usually displayed. Some PLCs will also offer the ability of the program to display custom messages for the automated control system.

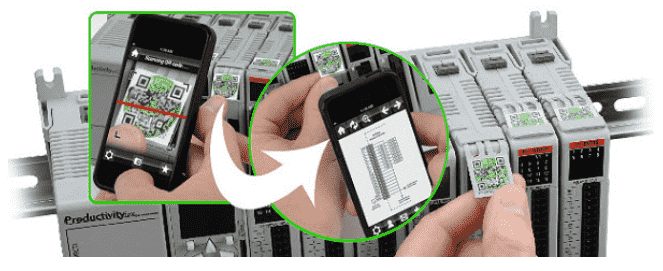

Automated systems will usually have documents and wiring diagrams within the control panel. This can be missing or unreadable over time.

Many modern PLC controllers will have QR codes that can be scanned so the latest information can be viewed for the item scanned. A smartphone is usually used as the interface to view this information.

Many modern PLC controllers will have QR codes that can be scanned so the latest information can be viewed for the item scanned. A smartphone is usually used as the interface to view this information.

PLC Programming Software

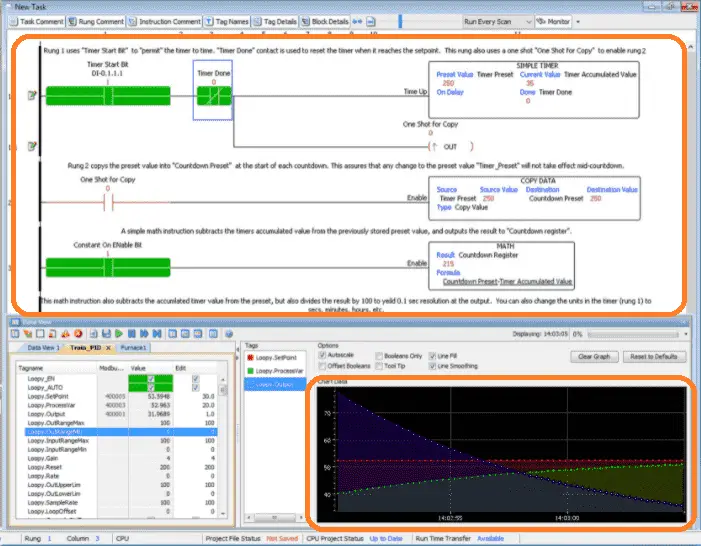

The PLC programming software offers a great HMI for maintenance and programmers.

Most PLC programming software will offer online monitoring of the inputs and outputs. Status can be visually shown on the ladder logic and graphs can be viewed. The program can be written, monitored, modified, and debugged. This HMI tool can be vital to keep a maximum machine uptime.

Most PLC programming software will offer online monitoring of the inputs and outputs. Status can be visually shown on the ladder logic and graphs can be viewed. The program can be written, monitored, modified, and debugged. This HMI tool can be vital to keep a maximum machine uptime.

Operator Panels (HMI)

Operator panels are usually for the actual running of the system. There are several different ways HMIs can control the machine or process.

Push buttons and lights can be individually added to the system. This is the simplest and universally understood in the industry. Above, we have a start-stop control using push buttons and lights.

Push buttons and lights can be individually added to the system. This is the simplest and universally understood in the industry. Above, we have a start-stop control using push buttons and lights.

Industrial panel displays are fully programmable and provide power and flexibility through a vast set of features. Screen objects such as Toggle, Slide Switch, Selector Switch, Throw Switch, Thumbwheel Switch, Meters, PID Faceplates, Analog/Digital Clock can all be programmed easily. When you have more than a few physical push buttons and lights, this HMI panel may be a better cost option.

Depending on the models, email, data logging, animation, and remote monitoring are just some of the features that are available.

One of the most common things to do today has the remote control on the operator’s personal phone. Control can happen without touching the actual machine panel itself.

One of the most common things to do today has the remote control on the operator’s personal phone. Control can happen without touching the actual machine panel itself.

SCADA – Communication Protocol

Supervisory Control and Data Acquisition (SCADA) is a communication tool that allows you to interact remotely with a process. This software usually collects data from several machines in a time interval. The information then can be used to control the process or logged for further analysis later.

SCADA systems today will usually incorporate an HMI and IoT Edge Solution for OEMs, System Integrators, and End Users

Internet of Things (IoT)

The Internet of Things (IoT) is a machine-to-machine communication tool. It can present information to users but is not necessarily its primary focus. PLCs can now be IoT edge devices. Edge devices communicate real-time data to a network.

MQTT is one of the communication protocols of IoT. This is because it is a report-by-exception protocol. (RBE) This means that there is state awareness. Data is only sent when there are changes to the state of the device or when data values change. This reduces the amount of data taking using up bandwidth resources.

Node-Red can be used as a data hub in your IoT solution. This is Low-code programming for event-driven applications. It can easily log, display, and communicate to several different devices. This software is also free.

We have discussed this exciting package and its capabilities using several different controllers.

Watch the video below to see how HMI is used for your automated equipment.

This concludes our PLC Learning Series. I hope that you have enjoyed this series as much as I have produced it. Thank you.

PLC Beginner’s Guide to PLC Programming

There are many different PLC manufacturers with different hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC you would then learn specifics for the controller that you will be programming.

This is the easiest way to learn about PLC programming.

Watch on YouTube: PLC Learning Series – HMI – Interfacing

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.

I have read all your article and think do PLC HMI

I am glad you found the articles informative.

Regards,

Garry