Contact and coil instructions are in every PLC program. The Productivity Suite Software consists of more than 82 instructions divided into 13 categories for the PLC. Contacts and Coils are two of the categories of instructions. Contact instructions include NO / NC, NO Edge / NC Edge and Compare. Coil instructions include Out, Set, Reset, OR Out, Flasher, Debounce, Timed, Toggle, Program End, and No Operation.

We will be looking at these instructions in the Productivity 1000 series PLC. Adding to our favorite instructions helps us to organize the instructions. We will also look at organizing your favorite instructions. Let’s get started.

Previously in this Productivity 1000 series PLC we have discussed:

System Hardware – Video

Installing the Software – Video

Establishing Communication – Video

First Program – Video

Documenting the Program – Video

Monitoring and Testing the Program – Video

Online Editing and Debug Mode – Video

Numbering Systems and Tag Database – Video

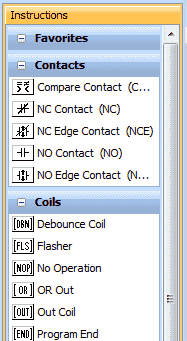

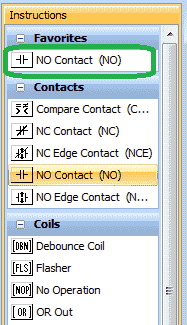

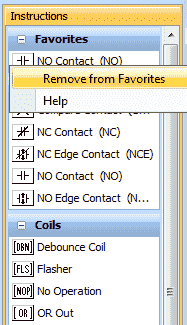

Favorites – Productivity Contact and Coil Instructions

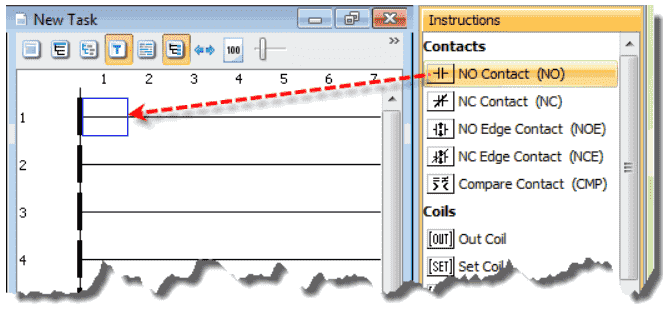

The favorites are a heading under the instructions window of the productivity suite software. You can click on the instructions window or use the main menu Tools | Instructions List to set the focus.

Right-clicking on the instruction will bring up a menu that will allow you to add to your favorites.

Click Add to Favourites.

This will now put the instruction under your Favourites.

Right-clicking on the instructions in your favorites will call up a menu that will allow you to remove the instruction.

Favourites are a good way to separate the instructions that you will be using more often.

Contacts – Productivity Contact and Coil Instructions

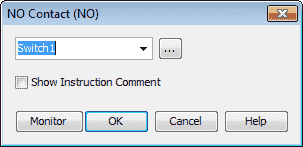

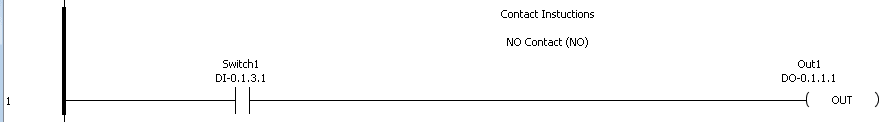

NO Contact (NO) – The normally open contact (NO) enables power flow in a run when contact is energized. It disables power flow when contact is de-energized.

Logic is solved left to right top to bottom on each scan. Here is a post that explains the scanning of the PLC.

https://accautomation.ca/understanding-the-plc-program-scan/

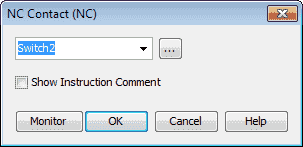

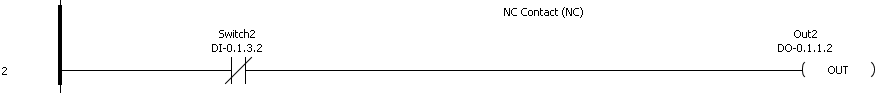

NC Contact (NC) – The normally closed contact (NC) enables power flow in a run when contact is de-energized. It disables power flow when contact is energized.

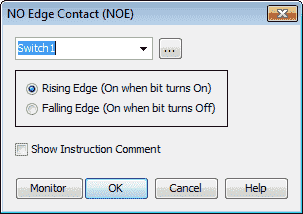

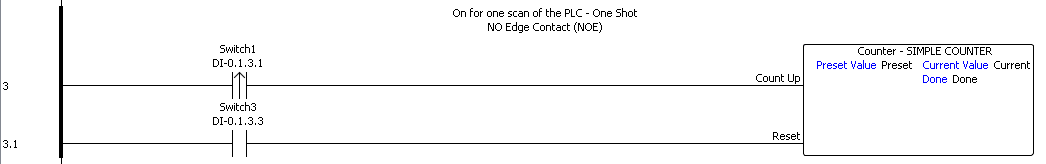

NO Edge Contact (NOE) – The normally open edge contact acts as a one-shot input on Rising Edge or Falling Edge signal. It allows power flow for one scan when contact is energized.

This is sometimes referred to as a one-shot in the PLC. Here is a post that discusses the one-shot logic using just a bit of logic.

https://accautomation.ca/how-to-make-a-one-shot-in-the-plc/

NC Edge Contact (NCE) – The normally closed edge contact acts as a one-shot input on the Rising Edge or Falling Edge signal. It allows power flow for one scan when contact is de-energized.

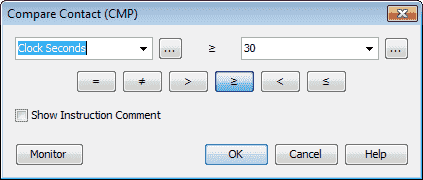

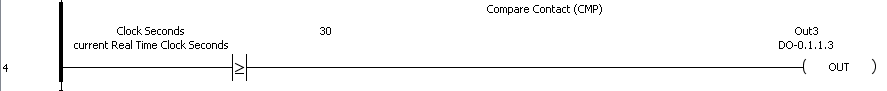

Compare Contact (CMP) – This input contact compares two numerical values and, according to a selected operand, enables or disables power flow in the rung based on the result of the operand.

In the example above, if the real-time clock seconds is greater than or equal to 30, the output Out3 will be on.

Coils – Productivity Contact and Coil

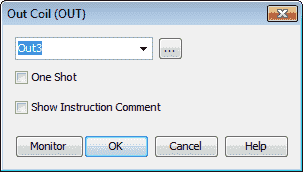

Out Coil (OUT) – This will provide an output that responds to the state of the rung. The one-shot selection will turn on the output for just one scan during a transition from off to on.

We have been using output coils in the above examples. The actual output can also be selected as a One-Shot. See the above link on how to make a one-shot in the PLC.

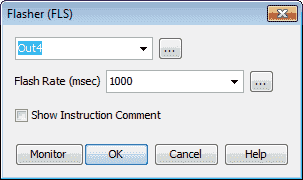

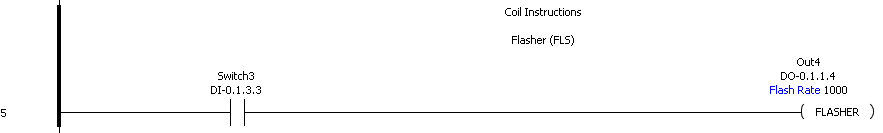

Flasher (FLS) – This will cycle an output bit on and off at a programmed rate.

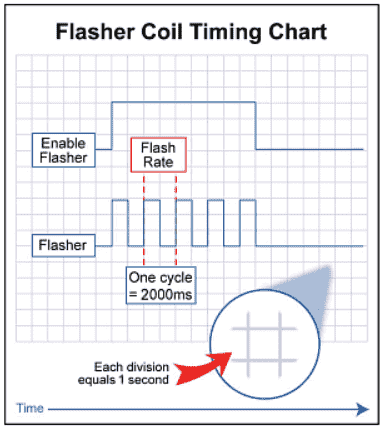

We set the flasher cycle time. In our case, we are using 1000 milliseconds. This means that the output Out4 will be on for 0.5 seconds and off for 0.5 seconds when the rung condition is true.

Here is the timing chart for the flasher instruction.

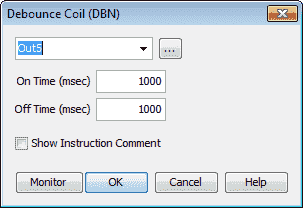

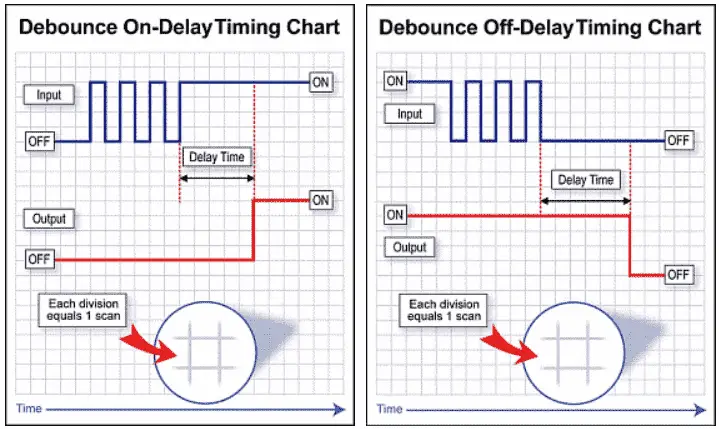

Debounce Coil (DBN) – Eliminate output coil chatter due to run-enabling contact bounce. Chatter will occur if our logic allows things to turn off and on quickly. If we compare input and that input changes quickly above and below the compared number, this would create chatter.

In our example, the rung condition must be on or off for 1000 milliseconds (1 second) before the output will activate or deactivate.

Here is the timing chart for the debounce coil instruction.

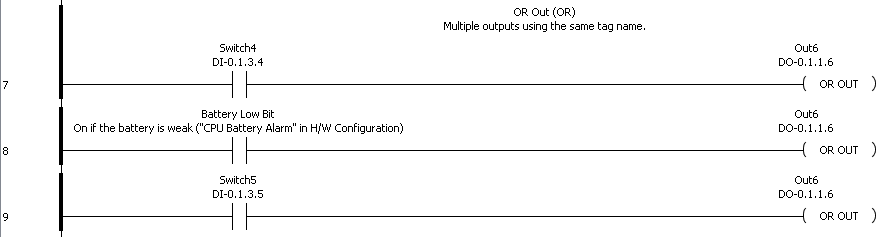

Or Out (OR) – This instruction allows an out coil with the same tag to be used in multiple rungs.

Note: The ability to have the same output in multiple rungs may make the troubleshooting of your logic difficult. In my experience this should be avoided.

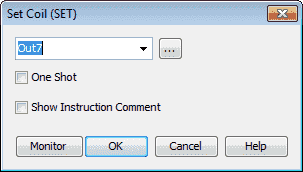

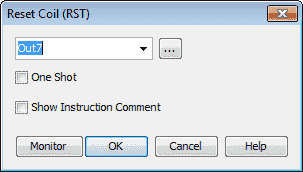

Set Coil (SET) – Set the output in a latched condition when the rung is enabled.

Reset Coil (RST) – Reset the output (unlatch) of a corresponding set coil.

The set and reset instructions are used together to turn on/off output. This is similar to the simple start-stop circuit that we discussed previously.

https://accautomation.ca/productivity-1000-series-plc-first-program/

https://accautomation.ca/how-to-make-a-start-stop-jog-circuit-in-a-plc/

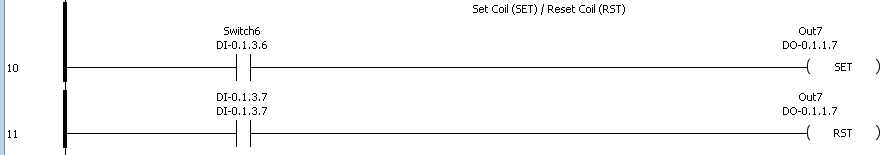

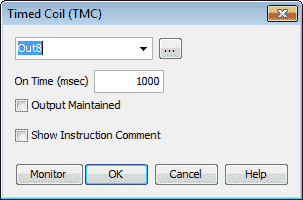

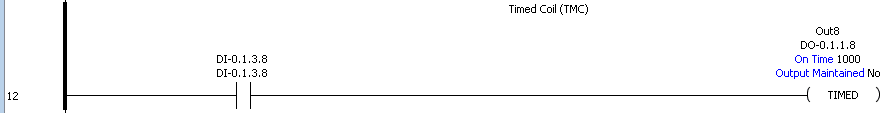

Timed Coil (TMC) – Hold the state of the output ON for a predetermined time.

The output will complete the timed value duration before turning off. Output maintained will enable the output to remain on after the time as long as the input condition is on.

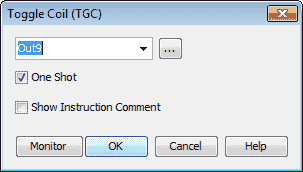

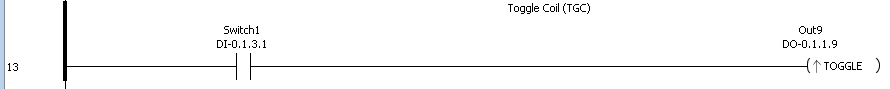

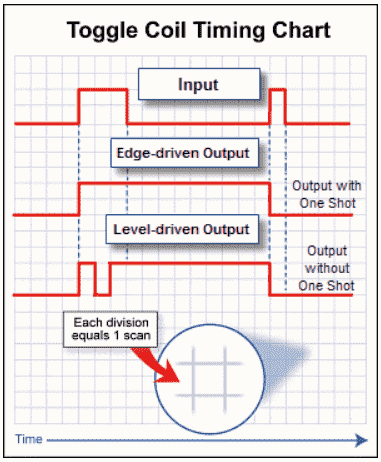

Toggle Coil (TGC) – Change the state of the output each time the rung is enabled. (Flip Flop)

In our example, when switch 1 is turned on the output will change state. If it is on then it will be turned off. If it is off then it will turn on. Here is a previous post explaining the logic behind the circuit.

https://accautomation.ca/creating-a-flip-flop-circuit-in-the-plc/

Here is the timing chart of the toggle coil instruction.

No Operation Coil (NOP) – Indicates that the rung will have no operation. It is sometimes used as a place holder in the ladder logic.

Program End Coil (END) – Marks the end of a task.

Download the program here.

Watch the video below to see the contact and coil instructions used in our Productivity 1000 Series PLC.

Productivity 1000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Programming Software (Free Download Link)

This software contains all of the instruction sets and help files for the Productivity Series.

Next time we will look at counter and timer instructions in the Productivity 1000 Series PLC.

Watch on YouTube: Productivity 1000 Series PLC – Contact and Coil Instructions

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.