If the Programmable Logic Controller (PLC) is the brain of an industrial automation system, the power supply is undoubtedly its heart. Without a clean, reliable flow of energy, the most innovative control systems in the world are just expensive paperweights.

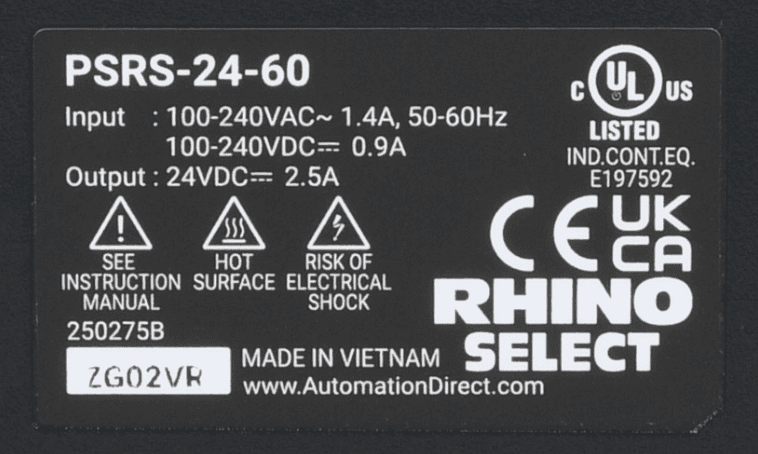

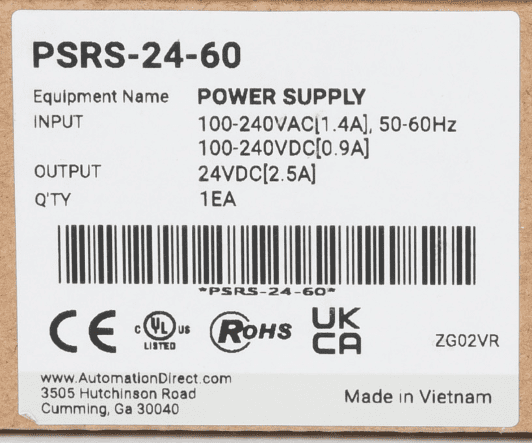

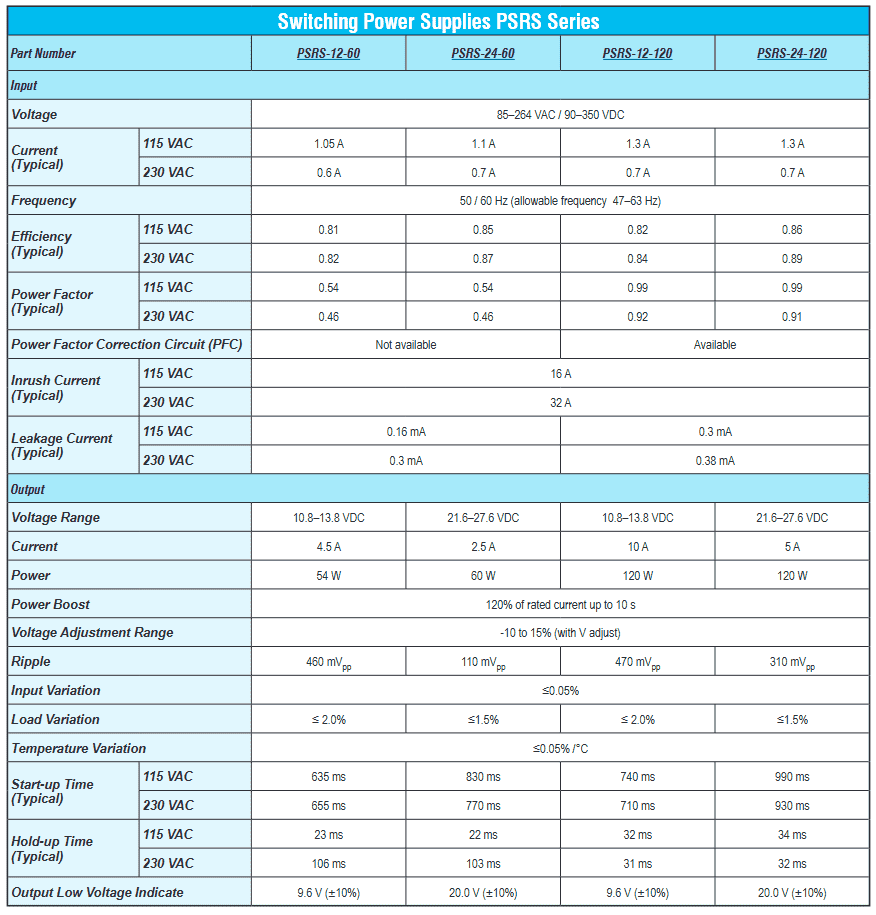

In the complex ecosystem of an industrial control cabinet, managing power isn’t just about turning things on; it’s about safety, reliability, and longevity. Today, we’re looking at a workhorse component designed exactly for this environment: the PSRS-24-60 power supply, and exploring why dedicated industrial power and proper installation practices are non-negotiable.

Why Do Industrial Cabinets Need Specialized Power Supplies?

Walk up to any industrial control panel. The power coming into that cabinet is usually raw, high-voltage AC—perhaps 120V, 240V, or even 480V three-phase. It’s powerful, but it’s also noisy, fluctuating, and inherently dangerous.

Conversely, the sensitive components inside the cabinet—the PLCs, sensors, HMIs, and safety relays—operate in a different world. They require stable, clean, low-voltage DC power (almost universally 24V DC in modern automation).

You cannot simply plug a sensitive DC sensor into a 480V AC line. You need a bridge that does more than just convert AC to DC; you need a device built to withstand the heat, vibration, and electrical noise typical of a factory floor, all while providing unwavering voltage regulation. Enter the power supply.

The Critical Role of Isolation

Beyond just converting voltage, the most vital function of an industrial power supply like the PSRS-24-60 is providing Galvanic Isolation.

Imagine a massive voltage spike occurring on the incoming AC mains line due to a nearby motor starting or a lightning strike. Without isolation, that spike could travel directly through to the DC side, instantly destroying sensitive (and expensive) control components.

Galvanic isolation physically separates the input (AC high-voltage) circuit from the output (DC low-voltage) circuit using a transformer. There is no direct metallic conductive path between the high side and the low side. Energy is transferred via magnetic fields.

Why this matters for your low-voltage circuits:

-

Component Protection: It acts as a firewall. Faults on the mains side do not propagate to the DC side.

-

Ground Loop Prevention: It helps prevent noise issues caused by differences in ground potential across a facility.

-

Personnel Safety (SELV): By isolating the output from dangerous line voltages, the 24V DC side becomes a Safety Extra-Low Voltage (SELV) circuit, which is significantly safer for technicians to work around for maintenance and troubleshooting.

Spotlight on the PSRS-24-60 Power Supply

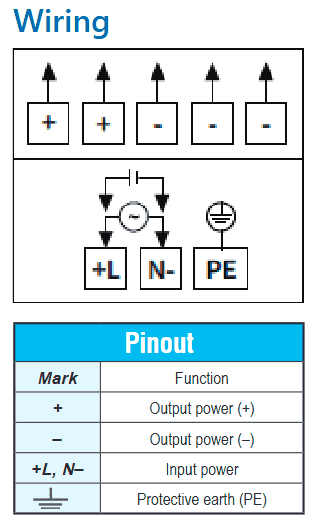

The PSRS-24-60 power supply is designed specifically to fill the critical gap between line power and control power.

As a 24V DC, 60-Watt supply, it occupies a “sweet spot” for many industrial applications. It provides enough power to run a standard PLC CPU, several input/output cards, and a handful of field sensors, without being overly bulky or expensive.

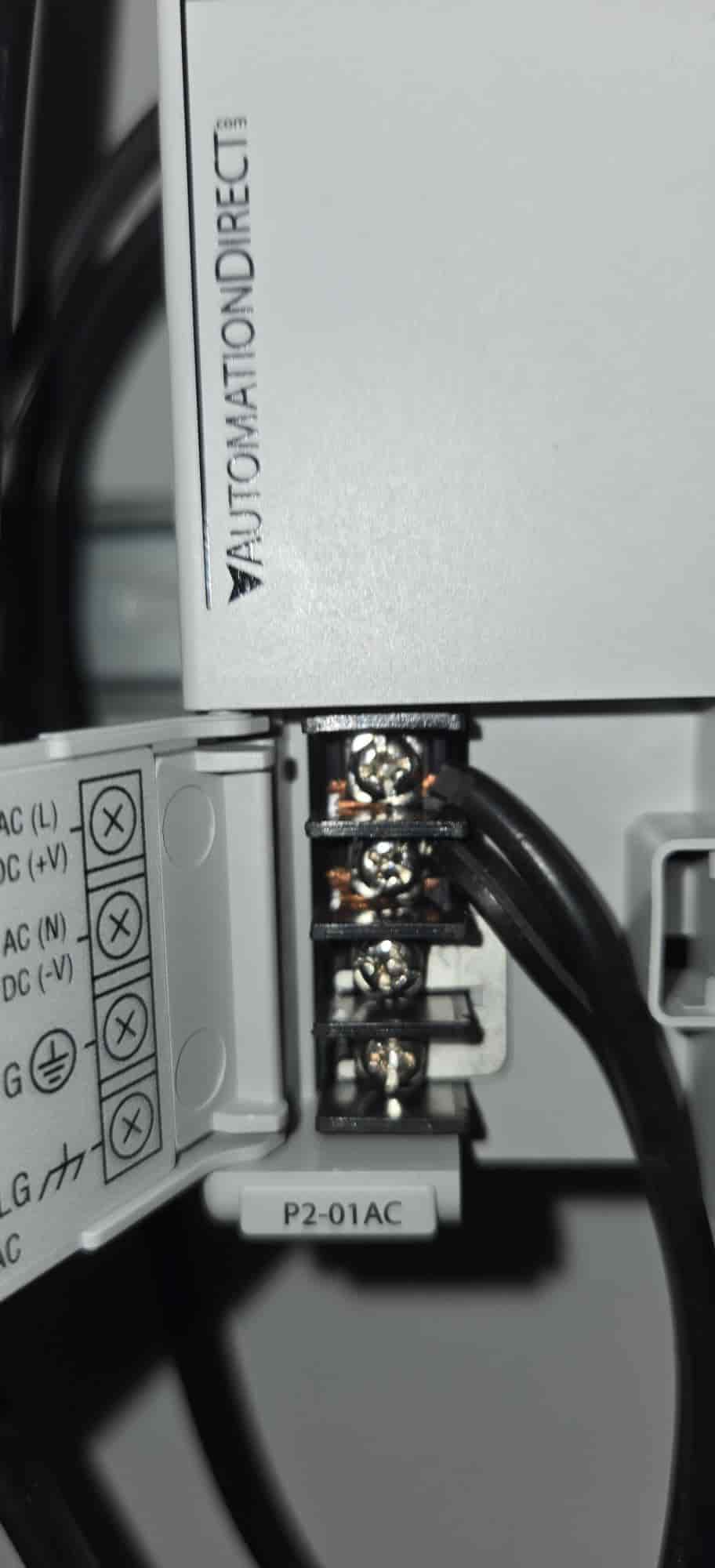

Designed for DIN-rail mounting, it integrates seamlessly into standard cabinet layouts, providing the necessary isolation and regulated DC power that keeps processes running smoothly without interruption.

Installation Corner: The Importance of Ferrules with Stranded Wire

We can’t talk about reliable power without talking about reliable connections.

In industrial cabinets, we almost exclusively use stranded wire rather than solid core wire. Stranded wire is flexible, making it easier to route through tight wire ducts, and it can withstand the constant vibration of machinery without work-hardening or snapping.

However, stranded wire has a weakness: screw terminals.

When you insert bare stranded wire into a terminal block or the input terminals of the PSRS-24-60 power supply and tighten the screw, several things go wrong:

-

Splaying: The twisting action of the screw pushes the strands apart.

-

Broken Strands: The sharp edge of the screw cuts some of the fine copper strands, reducing the current-carrying capacity.

-

Loose Connections (“Hot spots”): Over time, thermal cycling causes the splayed strands to settle, leading to a loose connection, increased resistance, heat buildup, and eventual failure.

The Solution: Use a Ferrule

A ferrule is a thin tin-coated copper tube crimped over the end of stranded wire.

Using a ferrule consolidates the strands into a solid, gas-tight mass. When you insert a ferruled wire into the PSRS-24-60 terminal block, the screw makes solid contact with the metal tube. This ensures maximum surface area contact, prevents oxidation between strands, and guarantees a vibration-proof connection that won’t loosen over time.

Using ferrules isn’t just “extra credit” work; it’s an industry best practice that ensures the reliable power delivered by your supply actually reaches the device that needs it.

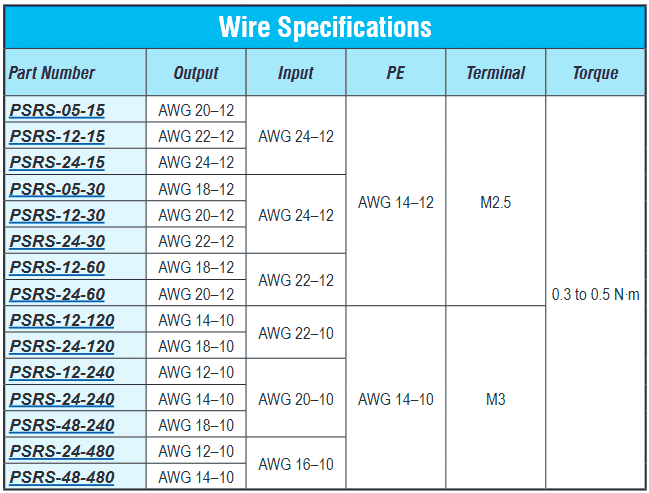

Wire Sizing Guide DC Power Supply

Selecting the correct wire size is crucial for safety and performance. Using a wire that is too small for the current load can lead to overheating, voltage drops, and potential fire hazards.

Below is a general guide for typical copper wire ampacity used in control panels.

Note: This chart is for general guidance only. Always consult local electrical codes (such as the NEC in the US or the CEC in Canada), wire manufacturer specifications, and consider factors such as ambient temperature, wire insulation type, and the number of conductors in a raceway when making a final selection.

| AWG (American Wire Gauge) | Typical Max Amperage (Approx. for Control Wiring) |

Common Use Case in 24V DC Circuits |

|---|---|---|

| 24 AWG | 2 – 3.5 A | Sensor signals, very low power devices. |

| 22 AWG | 3 – 5 A | Standard sensor and low-current I/O signals. |

| 20 AWG | 5 – 7.5 A | General I/O, slightly higher current loads. |

| 18 AWG | 7 – 10 A | Power distribution to remote I/O blocks, solenoids. |

| 16 AWG | 10 – 15 A | Main 24V DC distribution trunk lines, higher power loads. |

| 14 AWG | 15 – 20 A | Main power feeds for larger DC bus systems. |

Note: This chart is for general guidance only. Always consult local electrical codes (such as the NEC in the US or the CEC in Canada), wire manufacturer specifications, and consider factors such as ambient temperature and insulation type.

A reliable control panel starts with a stable foundation. By choosing a rugged, isolated power supply like the PSRS-24-60 and adhering to best installation practices, such as using ferrules and selecting the correct wire size, you ensure the long-term health and safety of your automation investments.

Ready to transform your approach to industrial automation? Discover how the Machines Simulator can revolutionize your training, development, and manufacturing processes. To learn or see more, click here. Click here to learn the five steps to PLC program development.

The best way to build the future is to simulate it first.

Watch on YouTube: Why Your PLC Dies Without the Right Power Supply!

There are many different PLC manufacturers with other hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC, you will then learn specifics for the controller you will be programming.

This is the easiest way to learn about PLC programming.

Here are the controllers that we have covered or are covering at ACC Automation:

LS Electric XGB PLC Series

BRX Do-More Series (Do-More Designer Software + Simulator)

Productivity Series P1000 / P2000

Click PLC Series

Omron CP1H Series

Horner XL4 PLC Series

Arduino Opta PLC

The EasyPLC Software Suite is a comprehensive package that includes PLC, HMI, and machine simulator software. This allows you to make a digital twin. See below to receive 10% off this software. This PLC learning package contains the following:

Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using the EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train, or practice your PLC programming.

Purchase your copy of this learning digital twin package for less than $95 USD for a single computer installation or less than $110 USD to allow access on multiple computers.

Receive 10% off the investment by typing in ACC in the comment section when you order.

Learn PLC programming the easy way. Invest in yourself today.

Examples of PLC program development using the five steps.

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Five Steps to PLC Program Development – Die Stamping

PLC Programming Example – Process Mixer

PLC Programming Example – Shift Register (Conveyor Reject)

PLC Programming Example – Paint Spraying

PLC Programming Example – Delay Starting of 7 Motors

PLC Programming Example – Pick and Place

PLC Programming Example – Sorting Station (Shift Register)

PLC Programming Example – Palletizer

If you have any questions or require additional information, please do not hesitate to contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to educate others on how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.