With today’s new processing and networking power, the future looks bright for programmable logic controllers and their programming. This has allowed the role of the PLC to expand.

System Design:

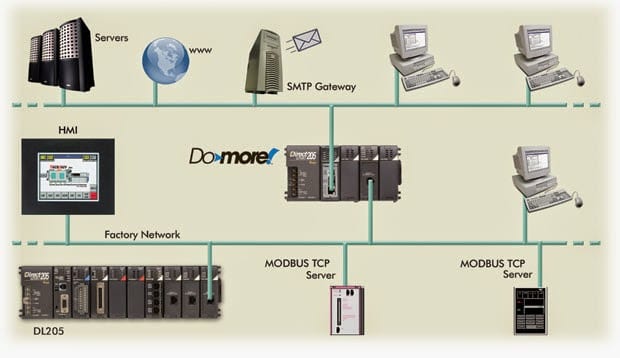

PLC design has changed significantly. Computer processing power has now added the following to programmable controllers:

- Micro USB slots (Data Storage)

- Ethernet ports

- WiFi

- RS232 / RS422 / RS485 (Serial Ports)

- Canbus

- Profibus

- DeviceNet

- Several digital I/O bus systems like ASi Bus

System design, more than ever, is done by asking even more questions about what is required when installing a PLC system.

- The number of input signals? Voltage levels? (Discrete on/off inputs.)

- The number of output signals? Voltage levels? (Discrete on/off outputs.)

- The number of analog input signals? Voltage and Current levels?

- The number of analog output signals? Voltage and Current levels?

- Is an operator Interface required? HMI – Human Machine Interface – This is a touch or functions key LCD or LED screen.

- Etc.

- Drives / Motors – What are you connecting to, and what is the communication system required?

- Computer network – Will this join your computer network? What is the connection cable and communication protocol?

- Do you need data collection?

- Do you need data displayed and controlled on a remote device such as a tablet or phone?

- Do you need email and text messages sent out by the PLC?

- Etc.

Programming:

- Ladder Diagram – Graphical structure

- Function Block Diagram – Graphical structure

- Structured Text – Textual structure

- Instruction List – Textual structure

- Sequential Function Chart – Graphical and Textual structure

Just about every manufacturer’s HMI screen will be programmed with different software. Due to the proprietary nature of communications, I would always use the manufacturer’s HMI with their PLC. The communications are usually directed to the memory areas and have a faster response time.

Computer

All our lives are based on desktops, laptops, tablets, and smartphones. Each of these will have an operating system like Windows, iOS, Android, etc. I believe it is always best to have some computer background information.

Higher-level languages such as Visual Basic (VB6) will allow you to run self-contained programs that can install on a computer and communicate with the network. I have used this to retrieve information from the PLCs on the production floor and save this information into a database.

Computer Network

The ability to share information in the company is essential. You cannot find a manufacturing plant without a computer network. We need to get the data from the plant floor to everyone on the Intranet and Internet. This can be done by setting up a web server and using basic HTML and ASP to deliver real-time data to the network from the PLC. This is usually confined to the ‘front office’ and is for email, engineering, and accounting.

http://www.w3schools.com/

W3school help me to deliver real-time data via email and web pages to the computer network.

HTML stands for hypertext markup language and is used for all web pages.

ASP stands for active server pages and communicates from a database to web pages.

HTML, ASP, Javascript, VBScript, etc., are all languages used to define the information shared on a computer network through a web server via a web client.

We have an abundance of information and ways to learn to program. The language and way will change depending on what you want to do. PLC programming is not just the logic behind discrete inputs and outputs on a machine but the entire system. It is the sharing and use of information for the organization.

I believe we are going and growing in the right direction with information sharing…

How do you see this change?

Let me know.

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.

Hi Garry,

I find this topic really interesting and I´m wondering if you have done already some practical use case covering this concepts related with the so called industry 4.0, e.g., real time systems retrieving data from the production floor into a database, allowing for the development of monitoring tools for supervision and/or subsequent analysis.

Thanks for the great work.

Regards,

Pedro Macedo

Hi Pedro,

Thank you for the comments on the website.

That is a great question. Yes, I have done several projects with the industrial internet of things. (IIoT or Industry 4.0)

On the website, I have included some of the information for you to explore.

Now You Can Have Robust Data Logging for Free

This is a 12 part series.

(PLC Program – Modbus TCP (VB6) – Access Database – Web Server)

Part 1 / 2 / 3 / 4 / 5 / 6 / 7 / 8 / 9 / 10 / 11 /12

How to Implement Modbus TCP Protocol using VBA with Excel

How to Send Email to SMTP Server (VB)

Here’s is a quick way to send email (text) messages from the PLC

How to Implement the Omron PLC Host Link Protocol (VB)

How to Implement the Omron Host Link Protocol Part 2 – VBA

Implementing the Omron Host Link Protocol (VB.net)

Implementing the Omron CX Server DDE and Excel

AdvancedHMI is a great program that is open-sourced. It is written in VB.net and runs on visual studio. VB.net is a great language to connect to databases. I have demonstrated in several posts connecting to a Click PLC, Productivity PLC, BRX (Do-More) PLC, Horner PLC and an Omron PLC.

Here is the game of Simon done with the Do-More Simulator (Free Download) and AdvancedHMI.

BRX (Do-More) PLC HTTP JSON Instructions

HTTPCMD – HTTP Request / Response with Server (BRX only)

JSONPARSE – Parse JSON Text (BRX only)

We will be using these instructions to read the weather conditions from a website.

MQTT stands for Message Queuing Telemetry Transport. This simple publish and subscribe communication protocol does not take too many resources. It has been said that it is the protocol of the internet of things.

BRX Do-More Simulator MQTT Publish / Subscribe

BRX Do-More PLC MQTT Communications

STRIDE MQTT GATEWAY MODBUS RTU TCP

STRIDE MQTT GATEWAY CLICK PLC MODBUS RTU TCP

STRIDE MQTT GATEWAY TO ADAFRUIT IO

Recently the C-More EA9 series has offered free IOS and Android Apps so you may view and control your HMI on a phone. You no longer need a screen. (Headless C-More) Here is a link to the series.

I hope this gives you some ideas of what is possible. If you have any questions please do not hesitate to ask.

Thanks again Pedro.

Garry