Accelerate Learning …

Accelerate Machines…

Accelerate Knowledge…

ACC Automation

What a difference a year makes! Social distancing, mask-wearing, hygiene, social circles, etc are just a few of the terms we hear every day in this Covid-19 world. Video conferencing with Zoom, Teams, and Google Meet are the norm in business today. Information is knowledge, and everyone wants to be able to see, control, and summarize production data on a regular basis. Technologies are merging and communicating like never before. What was impossible is now possible for the industrial plant floor. We are looking forward to the New Year and new possibilities for implementing your control solution.

Each year we like to take a few minutes and reflect on the past, current, and future of ACC Automation. You have helped us to build the site that you see today through questions, comments, and suggestions. Thank you.

2020 Yearly Review – ACC Automation

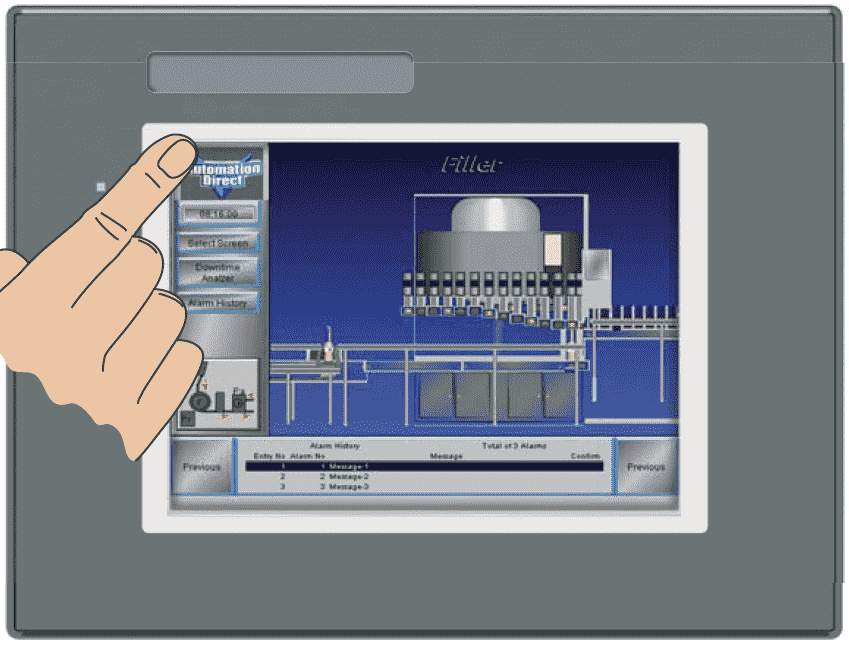

C-More EA9 Series Completed

Starting off the year we finished our C-More EA9 HMI (Human Machine Interface) series. File transfer protocol (FTP) and sending secured email on this versatile HMI was discussed.

C-More EA9 HMI Series Panel FTP File Transfer Protocol – Video

C-More EA9 HMI Series Panel Sending Email – Video

Stride MQTT Gateway

MQTT protocol is used for machine to machine (M2M), internet of things (IoT) communication. This publish/subscribe messaging is used where limited device resources are available or network bandwidth is low. The MQTT protocol provides small size, low power usage, minimized data packets, and efficient distribution of information to one or many receivers. This was previously discussed in our BRX Do-More Series.

Stride MQTT Gateway Modbus RTU TCP – Video

Stride MQTT Gateway Click PLC Modbus RTU TCP – Video

Stride MQTT Gateway to Adafruit IO – Video

C-More Headless HMI – EA9-RHMI

The Headless HMI was then introduced. All of the great features that are already built into the EA9 are available with the new headless model. This unit can be mounted within the cabinet and you can decide how to display the information.

C-More EA9 HMI Series Headless RHMI Panel – Video

C-More EA9 HMI Series Headless RHMI Setup Screens – Video

C-More EA9 HMI Series Headless RHMI Remote Control – Video

Note: This year the EA9 Programming Software, as well as the remote apps for Android and IoS, became free downloads.

C-More EA9 HMI Series Headless RHMI to Solo Process Temperature Controller – Video

C-More EA9 HMI Series Headless RHMI to Solo and Click PLC Controllers – Video

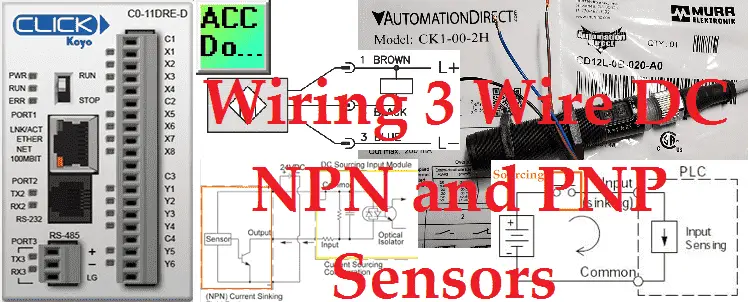

3 Wire Sensor Wiring

One of the more popular questions I receive is around terminology and wiring of 3 wire sensors. The following post was put together to explain PNP, PNP, Normally Open, Normally Closed, Sourcing, and Sinking a load.

Wiring 3 Wire DC NPN and PNP Sensors – Video

Capacitive Pushbutton Sensor Switch /Indicator – Video

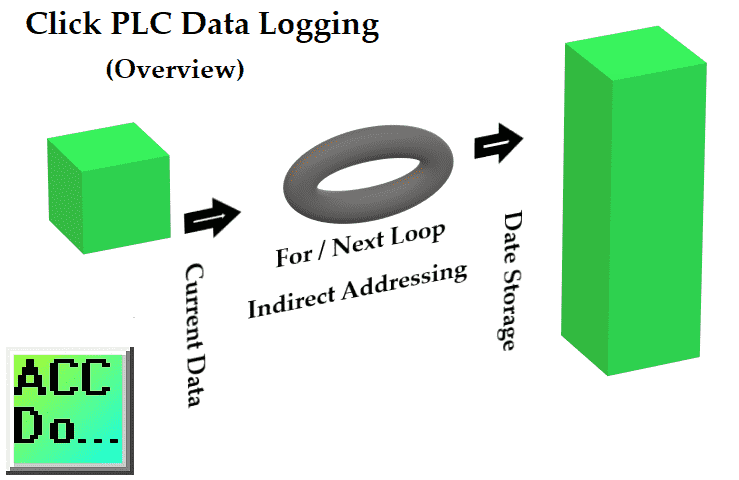

Click PLC Indirect Addressing Example

The Click PLC can perform indirect addressing. This means that I can ask for information to be moved to and from locations in the PLC using a pointer that will indicate the address. This was discussed in the following popular post:

Click PLC Logging Data with Time and Date Stamp – Video

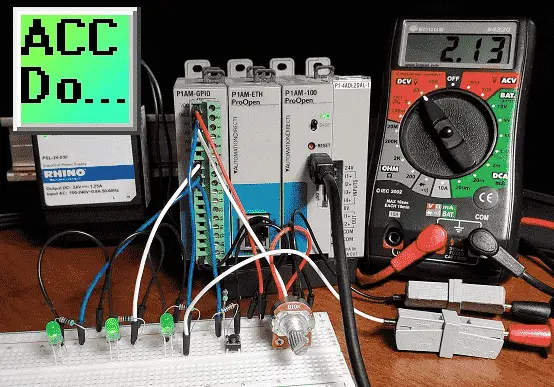

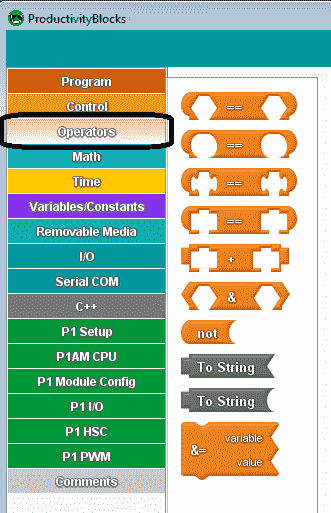

Productivity Open P1AM Industrial Arduino Controller

Productivity 1000 (P1) Cards

Productivity Open is an industrial rated Arduino compatible platform controller. This rugged open-sourced CPU mimics the MKRZero Arduino. You can add standard MKRZero shields (Add-on Boards), along with the Productivity 1000 PLC I/O. The Productivity Open Arduino Compatible Industrial Controller is CE and UL certified. Approved industrial standards ensure that your panels operate equipment and systems in a wide range of industrial environments and enable the safe functioning of equipment. Industrial electrical noise isolation has been incorporated in the design of the Productivity Open. Voltages up to 240VAC can now be used with up to 3A output ratings on your maker project.

Productivity Open Arduino P1AM Series

YouTube Video of Arduino P1AM Series

We started and currently are still in this series.

Stride Field I/O

The Stride Field I/O Modules are simple and compact. They provide an economical means to connect inputs and outputs to an Ethernet Modbus TCP communication network. Every module operates as a standalone Modbus TCP server and can be configured via a built-in web server.

Stride Field Remote IO Modules Modbus TCP Ethernet

– Powering and Configuration Video

– Unboxing Video

Click PLC to Stride Field IO Modbus TCP – Video

Productivity 1000 PLC to Stride Field IO Modbus TCP – Video

BRX Do-More PLC to Stride Field IO Modbus TCP – Video

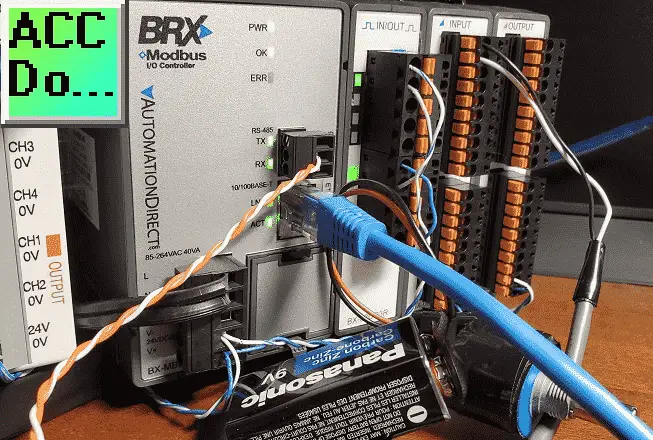

BX-DMIO – BRX Do-More PLC Ethernet Remote IO Controller

The BRX Do-More PLC has its own line of remote input and output expansion units. You can add up to 8 I/O expansion units per controller (CPU) and 8 BRX expansion modules per expansion unit. This will make your system grow with your needs.

The remote I/O expansion units feature the following:

• All units have built-in Ethernet port, 10/100 Mbps

• MBIO units have onboard RS-485 port with removable 3-Pin connector

• Support for 8 expansion modules

BRX Do-More PLC Ethernet Remote IO Controller BX-DMIO

– Programming and Configuration Video

– Hardware Video

Modbus RTU TCP Remote IO Controller BX-MBIO

– Powering and Configuration Video

– Hardware Video

BRX Do-More PLC to Modbus TCP RTU Remote IO Controller BX-MBIO – Video

Click PLC to Modbus TCP RTU Remote IO BX-MBIO – Video

Productivity 1000 PLC to Modbus TCP RTU BX-MBIO – Video

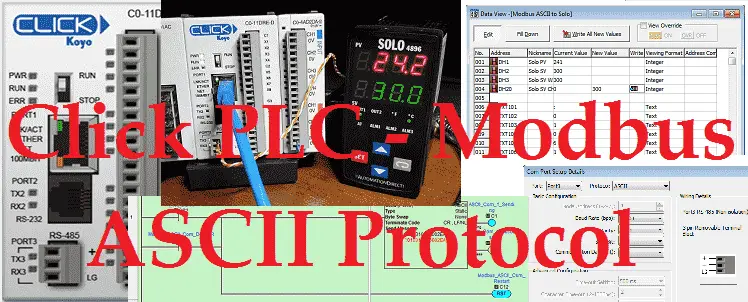

Modbus ASCII Protocol

Modbus is a communication method used for transmitting information over serial lines between electronic devices. The device requesting the information is called the Modbus Master (Client) and the devices supplying information are Modbus Slaves (Servers). This protocol was originally developed by Modicon systems.

Modbus protocol comes in basically three different types. Ethernet (Modbus TCP) or Serial (Modbus RTU or Modbus ASCII). Modbus TCP and Modbus RTU come as standard protocols in the productivity, BRX, and Click series of PLCs. We show how this protocol can be done in each of these PLC systems.

Click PLC Modbus ASCII Protocol Communication – Video

Productivity 1000 PLC Modbus ASCII Protocol – Video

BRX Do-More PLC Modbus ASCII Protocol – Video

Currently, we are in the process of our Productivity Open P1AM Arduino Series and we just started the Arduino Uno Super Starter Kit. This will be a great introduction to electronic circuits. We will continue in the New Year with versatile easy to use controllers.

Looking forward to the future…

2021 will prove to be an exciting time. Here are some of the items that we have planned.

Node-Red – flow-based development tool for visual programming developed originally by IBM for wiring together hardware devices, APIs, and online services as part of the (Industrial) Internet of Things. We will also continue by looking at the MQTT communication protocol used with the IIoT.

More examples of Factory IO – 3D simulation of your process – This will be used in conjunction with the Productivity Suite Simulator. The simulator has been a great addition to the productivity line of programmable automation controllers (PACs).

As always we will be answering your questions and applications so you can quickly implement your control solution. Once again we thank you for supporting this site.

Watch on YouTube: ACC Automation 2020 Yearly Review – What’s Next

If you have any questions or need further information please contact me.

Thank you once again for supporting the website in 2020!

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.