Did you know that over 500 articles and tutorials are now freely available on ACC Automation? That’s right—more than a decade of accumulated PLC programming knowledge, HMI design guides, communication tutorials, and hands-on examples waiting for you to explore, all without spending a dime. Whether you’re a complete beginner trying to understand your first rung of ladder logic or a seasoned controls engineer looking for that one specific Modbus configuration tip, there’s something here for you.

As we wrap up another year of learning PLC programming at ACC Automation, we’re excited to reflect on the progress, innovations, and milestones we’ve achieved in 2025. This year has been filled with growth, learning, and pushing the limits of industrial automation.

Let’s highlight some key events from the year. ACC Automation Review

January – February: Node-RED Integration Takes Center Stage – ACC Automation Review

We kicked off 2025 with extensive coverage of the Click PLUS C2-NRED module. This Node-RED integration opened up incredible possibilities for connecting PLCs to IoT platforms, dashboards, and cloud services.

The series covered everything from basic installation to advanced node configurations and Modbus TCP communication between Node-RED and both the BRX Do-More and Click PLCs. For those looking to bridge the gap between traditional PLC programming and modern IoT connectivity, these tutorials provided a practical pathway forward.

Click PLC Series – Node-RED Integration

March – April: Modbus Communication Deep Dives – ACC Automation Review

Spring brought comprehensive Modbus communication tutorials. We explored RS-485 serial connections, demonstrating proper wiring techniques and configuration settings that many beginners struggle with. The Click PLC Modbus RS-485 series became one of our most-referenced resources.

We also continued expanding the Click PLC series with topics ranging from remote I/O configurations using Stride Field modules to the BX-MBIO Modbus TCP/RTU remote I/O controller. Real-world communication scenarios that control engineers face daily were addressed with step-by-step solutions.

May – June: PLC Simulators and Baggage Claim Automation – ACC Automation Review

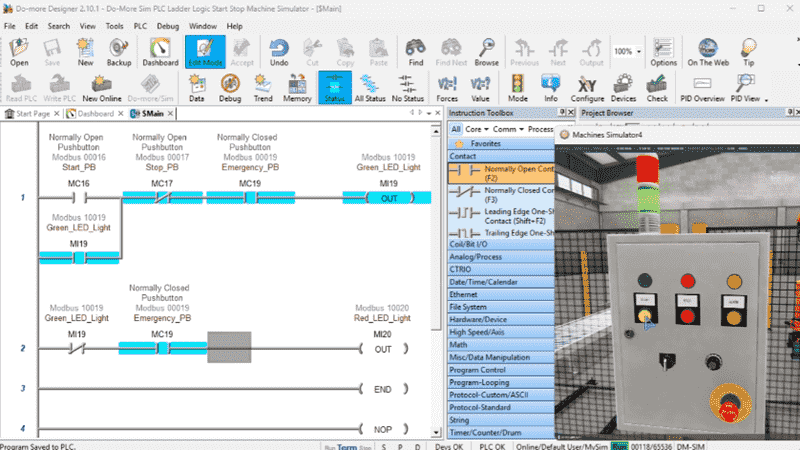

In May and June, we doubled down on the importance of PLC simulators for learning. The posts emphasized how simulators can reduce programming development time by up to 50 percent—a claim backed by real experience.

The airport baggage claim automation series captured the reader’s attention. Globally, airlines handle over 4 billion bags annually, with 99.6 percent arriving on time. We explored how PLC programming enables this, walking through the design and programming of an automated baggage handling system. The troubleshooting follow-up addressed sensor issues and PLC tweaks that maintenance technicians encounter in the field.

PLC Simulator CONQUER Your Automation Potential!

Automate Airport Baggage Claim – PLC Programming!

July: PLC Programming Myths Exposed- ACC Automation Review

July tackled something different—the myths and misconceptions that hold beginners back from mastering PLC programming. We addressed common fears and misunderstandings that prevent people from diving into industrial automation, providing clarity and encouragement for those just starting their journey.

The free Click PLC software post reminded everyone that professional-grade programming tools don’t always come with professional-grade price tags. AutomationDirect’s commitment to free software downloads continues to lower barriers for learners worldwide.

Exposing the Secrets of PLC Programming Myths!

FREE CLICK PLC Software: Is It REALLY That Easy?

August: Timers, Static IP, and Why Simulators Matter – ACC Automation Review

August focused on foundational topics that every PLC programmer needs to master. The Click PLC timer tutorial walked through practical applications using a story-driven approach—Mark, a veteran automation engineer dealing with conveyor bottlenecks, served as our guide through timer configuration and troubleshooting.

We also covered static IP assignment on the Click PLUS PLC, an essential skill for anyone setting up networked control systems. The simulator advocacy continued with content explaining why every beginner needs hands-on practice before touching real hardware.

Master the Clock: Using Timers in the Click PLC

Assign Static IP to CLICK PLUS PLC Easily!

Why Every Beginner Needs a PLC Simulator Now!

September: PLC Scan Cycles and Ladder Logic Fundamentals – ACC Automation Review

September dove deep into the mechanics of how PLCs actually work. Understanding scan cycles—how PLCs process inputs, execute programs, and update outputs in a continuous loop—separates proficient programmers from those who struggle with timing issues and unexpected behavior.

We addressed the most commonly asked ladder logic questions and explored why specific logic patterns confuse beginners. These fundamental concepts apply regardless of which PLC brand you’re working with.

What is PLC Logic in Scan Cycles REALLY Doing?

Most Asked PLC Ladder Logic Question and Why

October: AI Meets PLC Programming – ACC Automation Review

October marked a significant milestone—exploring the intersection of artificial intelligence and PLC programming. The Claude AI post investigated whether modern AI tools could successfully assist with PLC programming tasks. This emerging technology presents fascinating possibilities for how we’ll develop and troubleshoot control systems in the future.

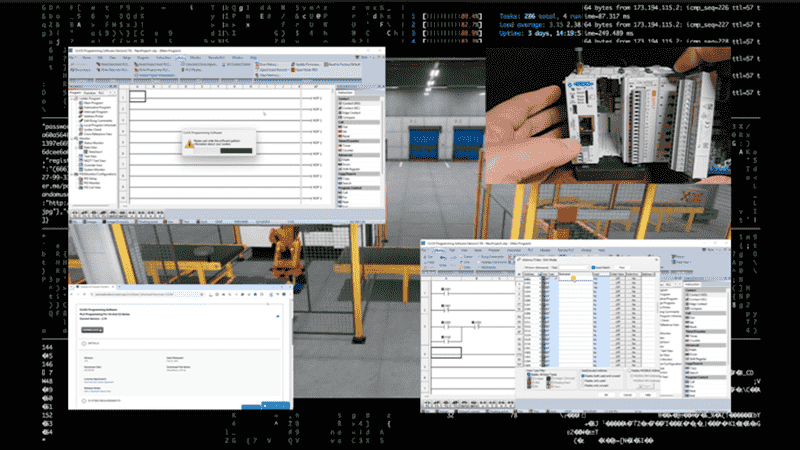

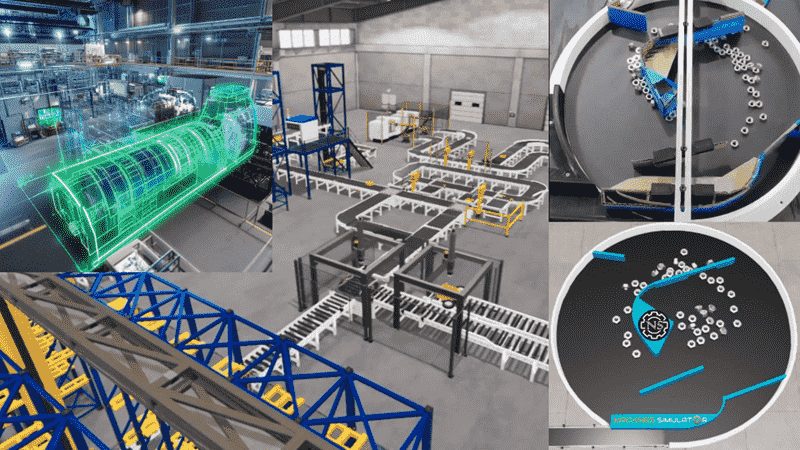

Digital twins also received attention, examining how virtual replicas of physical systems can transform factory operations. The Machine Simulator software suite continues to provide hands-on digital twin capabilities for learners and professionals alike.

Can I Use CLAUDE AI to Program a PLC Successfully?

What if DIGITAL TWINS Could Transform Your Factory?

December: Power Supplies, Wiring Best Practices, and Ferrules – ACC Automation Review

We’re closing out 2025 with essential infrastructure topics. The PSRS-24-60 power supply post addressed why PLCs die without proper power—covering galvanic isolation, voltage regulation, and the critical role power supplies play in control system reliability.

Wiring best practices received dedicated attention, particularly the use of ferrules with stranded wire. This seemingly simple topic prevents countless field failures. When stranded wire meets screw terminals without proper termination, connections loosen, strands break, and systems fail. Ferrules elegantly and inexpensively solve this problem.

Ethernet switch selection for industrial networks is also currently under development, addressing the networking infrastructure that ties modern control systems together.

Why Your PLC Dies Without the Right Power Supply!

Looking Forward to 2026

As the year draws to a close, we’re already planning next year’s content.

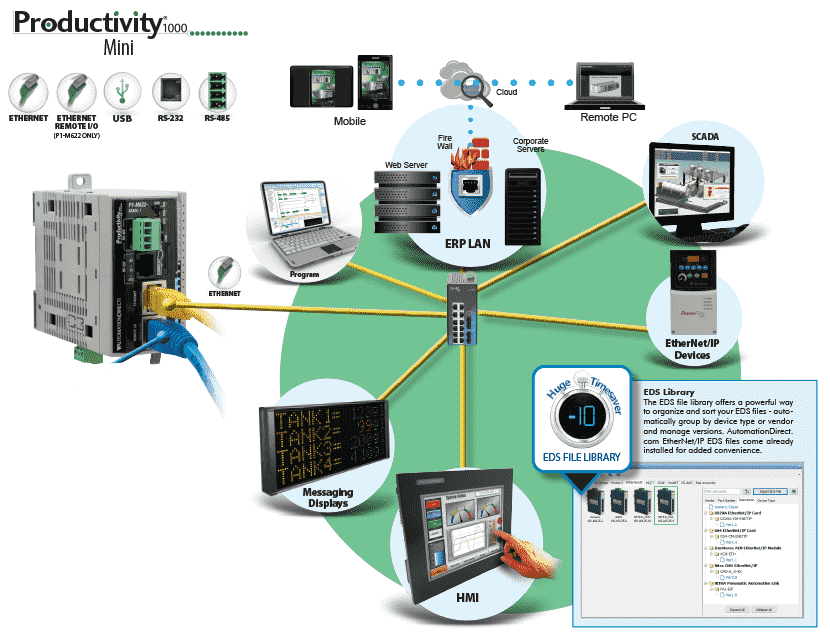

Expect coverage of the Productivity Mini PLC series—compact controllers with built-in I/O that represent an exciting evolution in the Productivity family. The C-More CM5 HMI series will continue receiving attention as we explore its enhanced capabilities and integration options.

Perhaps most exciting is our planned exploration of AI with Model Context Protocol (MCP) for industrial automation applications. The convergence of artificial intelligence and traditional control systems opens possibilities we’re only beginning to understand.

2025 was filled with growth, innovation, and meaningful connections at ACC Automation. We introduced practical tutorials, shared hands-on programming examples, and continued building resources that help people learn industrial automation without expensive training courses or equipment investments.

As we enter 2026, we remain committed to supporting readers and viewers in their automation projects. Thank you for being part of the ACC Automation family. Here’s to another year of success and progress!

As always, we will answer your questions and applications so you can quickly implement your control solution.

Accelerate Learning… Accelerate Machines… Accelerate Knowledge… ACC Automation

Watch on YouTube: ACC 2025 500+ Free PLC Ladder Logic HMI Decade Knowledge Base

To learn more about the Machine Simulator and digital twins for PLC learning, click here.

Click here to view the entire series on the Click PLC.

If you have any questions or need further information, please get in touch with me. Thank you once again for your support in 2025!

Regards,

Garry

ACC Automation

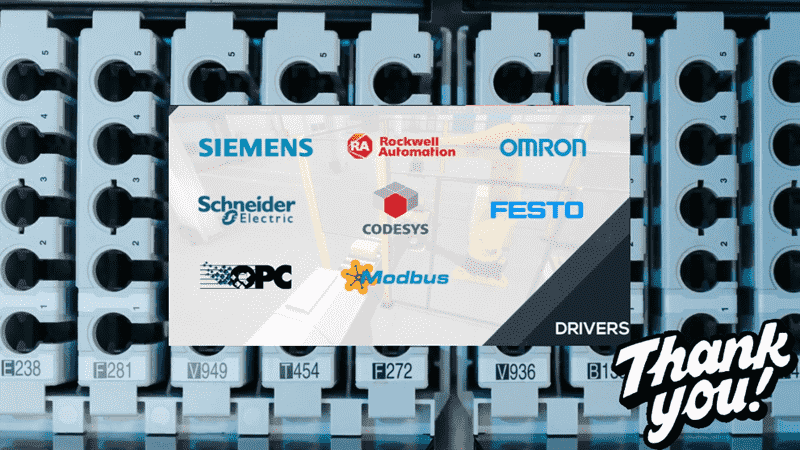

There are many different PLC manufacturers with other hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC, you will then learn specifics for the controller you will be programming.

This is the easiest way to learn about PLC programming.

Here are the controllers that we have covered or are covering at ACC Automation:

LS Electric XGB PLC Series

BRX Do-More Series (Do-More Designer Software + Simulator)

Productivity Series P1000 / P2000

Click PLC Series

Omron CP1H Series

Horner XL4 PLC Series

Arduino Opta PLC

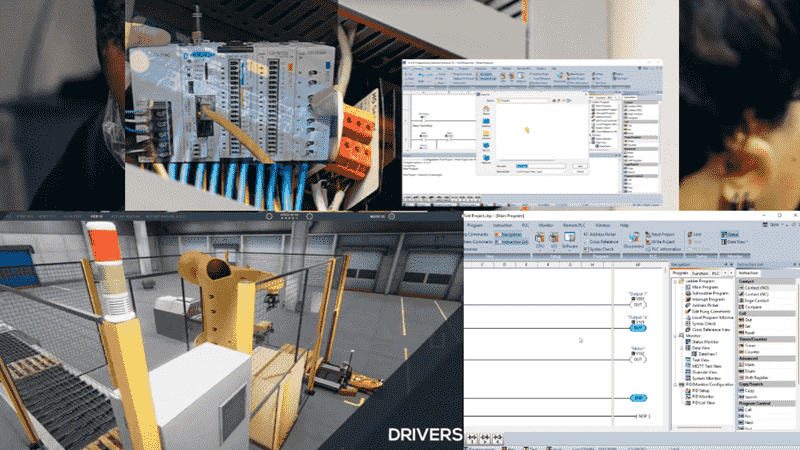

The EasyPLC Software Suite is a comprehensive package that includes PLC, HMI, and machine simulator software. This allows you to make a digital twin. See below to receive 10% off this software. This PLC learning package contains the following:

Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using the EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train, or practice your PLC programming.

Purchase your copy of this learning digital twin package for less than $95 USD for a single computer installation or less than $110 USD to allow access on multiple computers.

Receive 10% off the investment by typing in ACC in the comment section when you order.

Learn PLC programming the easy way. Invest in yourself today.

Examples of PLC program development using the five steps.

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Five Steps to PLC Program Development – Die Stamping

PLC Programming Example – Process Mixer

PLC Programming Example – Shift Register (Conveyor Reject)

PLC Programming Example – Paint Spraying

PLC Programming Example – Delay Starting of 7 Motors

PLC Programming Example – Pick and Place

PLC Programming Example – Sorting Station (Shift Register)

PLC Programming Example – Palletizer

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to educate others on how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.