The C-More EA9 Series of human-machine interfaces (HMI) provides a way for the operator to control and will perform a lot of additional items. The free programming software is very user friendly and fully featured. Here are some of the additional items that this robust and powerful HMI can do besides communicating to programmable logic controllers (PLCs).

Send Email – This includes authentication for the email client protocol

Log Data – This can log data files to the internal memory or an external thumb drive (32G)

FTP Server – Use file transfer protocol to retrieve information from the HMI to a network. This can be done automatically with a batch file.

Web Server – This HMI can be a web server on your network

Remote Internet Access – Windows, Android, and IOS operating systems have the ability to take advantage of this remote access to the HMI. The programs are free and fully functional.

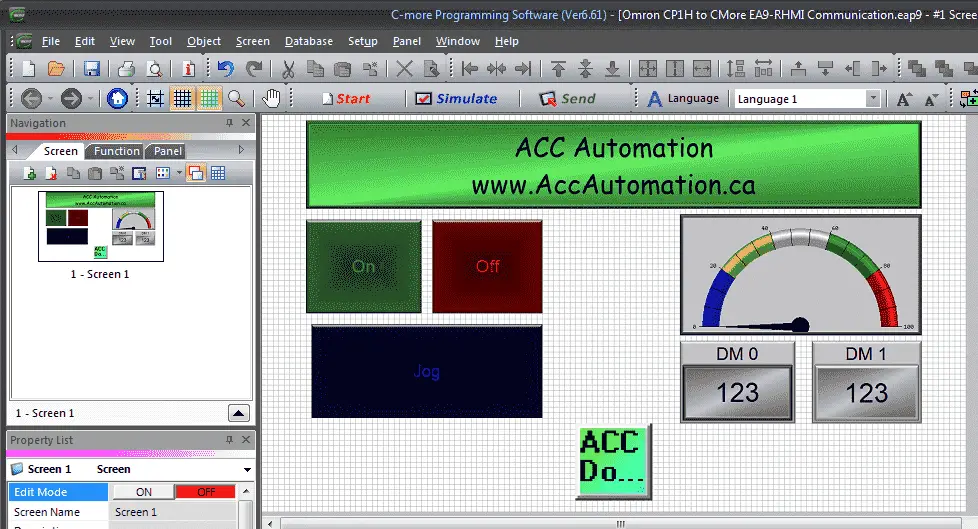

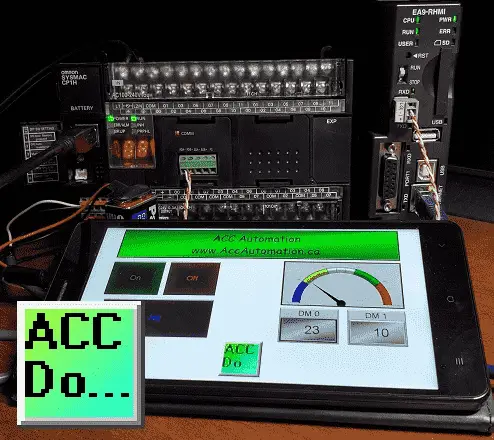

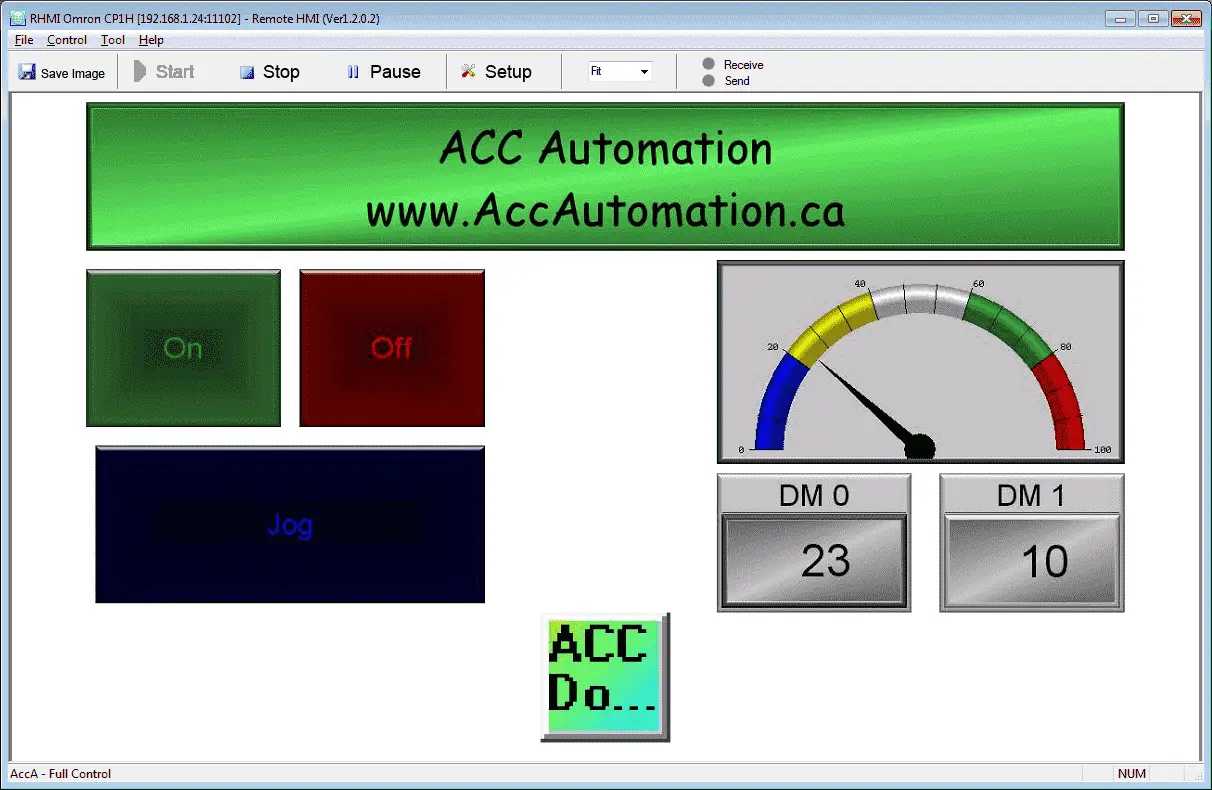

Our sample CP1H PLC program will use buttons and indicators to control a start/stop jog circuit. An analog input into the PLC will be scaled and displayed on a gauge and numeric display on our HMI screen. We will also write information to our 7 segment display on the CPU from our HMI screen. Omron serial host link protocol will be used to communicate over an RS485 serial cable. We will demonstrate remote access using our windows and android device. Let’s get started.

Previously in this CP1H series we have discussed:

System Hardware – Video

CX-Programmer – Video

Establish Communication – Video

Setting, Forcing and Online Editing – Video

Numbering System and Addressing – Video

CP1H Timers – Video

Counters – Video

Data Movement – Video

Compare Instructions – Video

Data Shift Instructions

– Video Part 1

– Video Part 2

Math Instructions – Video

Data Conversion – Video

Program Control Instructions – Video

Table Data Instructions – Video

Data Control Instructions – Video

AdvancedHMI Communication – Video

The CP1H PLC can communicate Host Link (C Mode Commands) Serial – RS232, RS485, RS422. It can also communicate Ethernet FINS via a communications module.

Communications drivers currently included in the C-More HMI for the Omron controllers are as follows.

• Omron C200 / C500 Host Link Adapter

• Omron CS / CJ FINS Serial

• Omron CS / CJ FINS Ethernet

These will handle communication with any of the Omron Series of programmable logic controllers.

Hardware

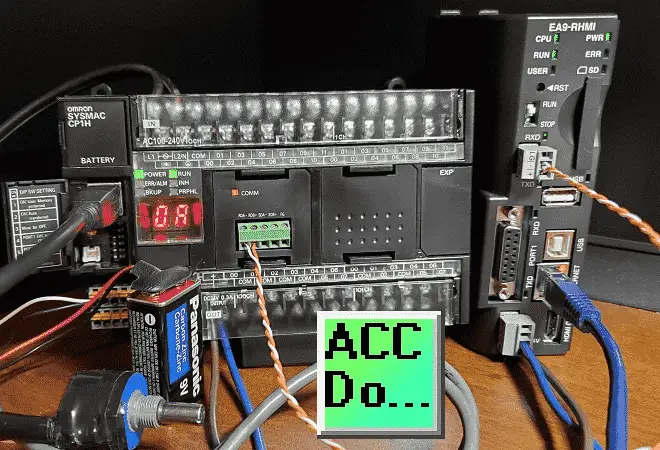

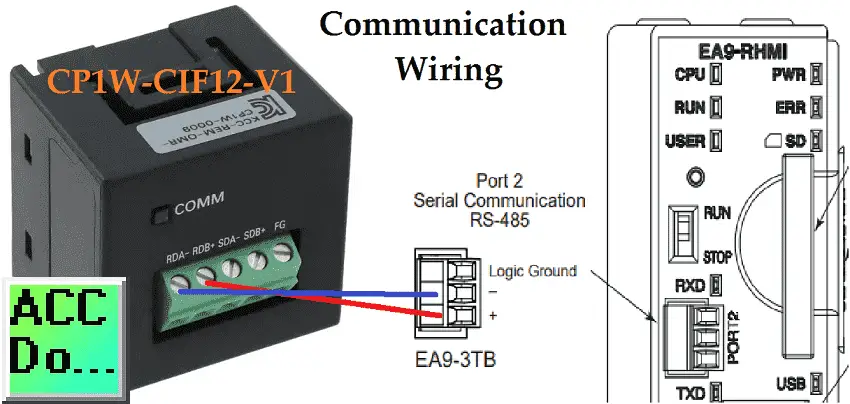

We will be connecting the C-More HMI model EA9-RHMI to the Omron CP1H-XA40DR-A PLC. The Omron also has a communication plugin module part number CP1W-CIF12-V1. This is an RS485 communication module that will use Omron host link serial commands.

Communication Wiring

RS485 is a two-wire system. Port 2 of the HMI will communicate to the plugin Omron communication module.

CP1H Program

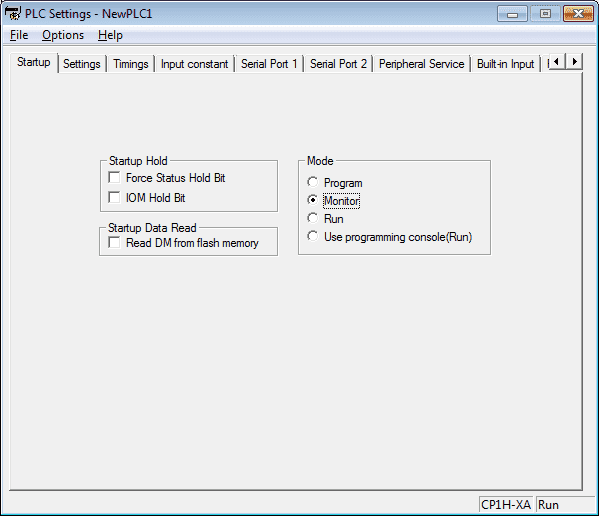

The Omron PLC defaults to Run mode. (Use programming console (Run)) This is the mode of the CP1H when it is powered. (Supply voltage applied) Communication with the CP1H will be done through the serial port. In order to change parameters in the PLC, this mode must be in Monitor for the Omron PLC.

Using CX-Programmer we can go to the PLC Settings and change the start-up to monitor mode.

(main menu | PLC | Edit | Settings…)

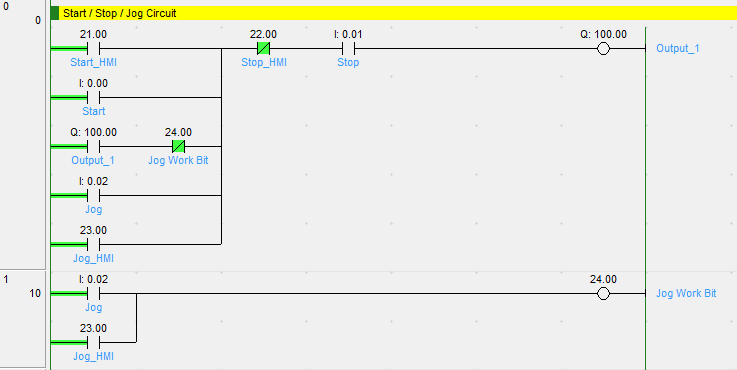

Start Stop Jog Circuit

The following link will explain the code for the circuit.

How to make a start-stop jog circuit in a PLC.

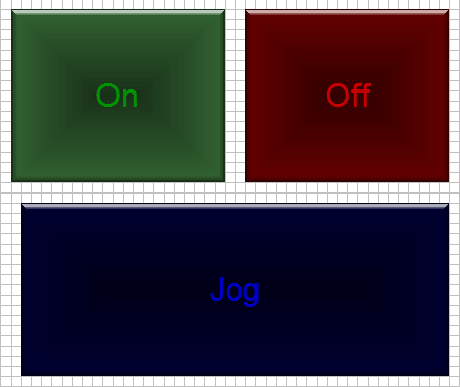

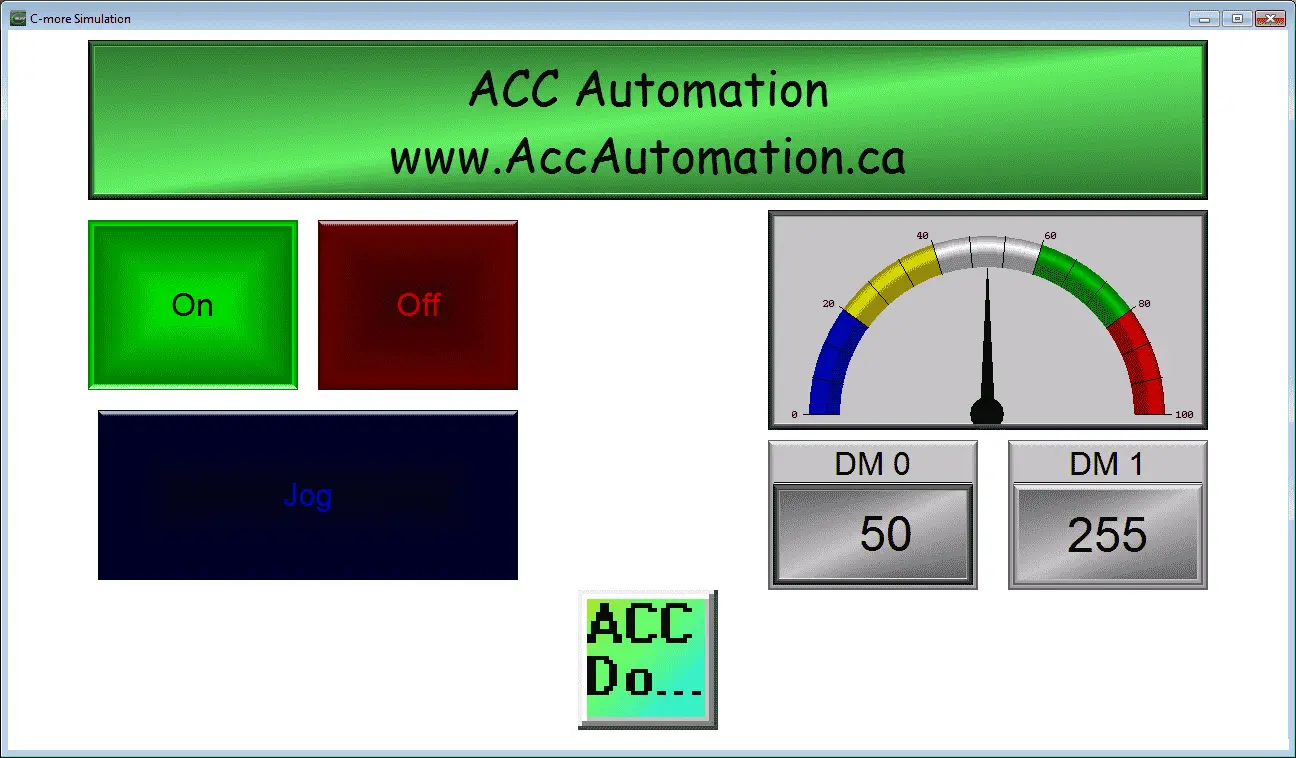

The C-More HMI Screen will use three momentary buttons and one pilot light.

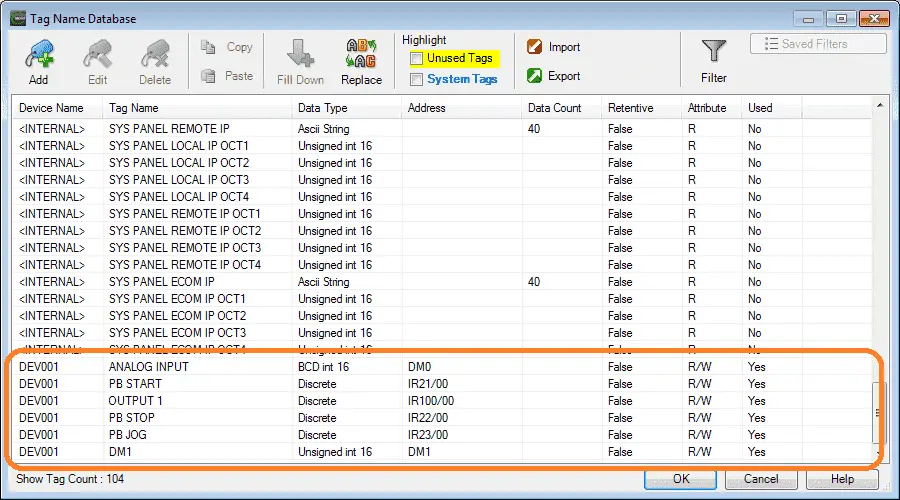

The PLC Address will be set for the following:

Start – IR21/0

Stop – IR22/0

Jog – IR23/0

Output – IR100/00

Analog Input – Gauge display

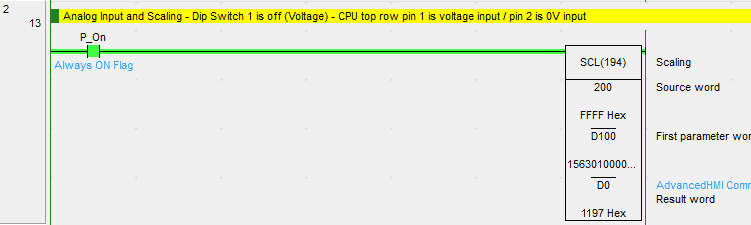

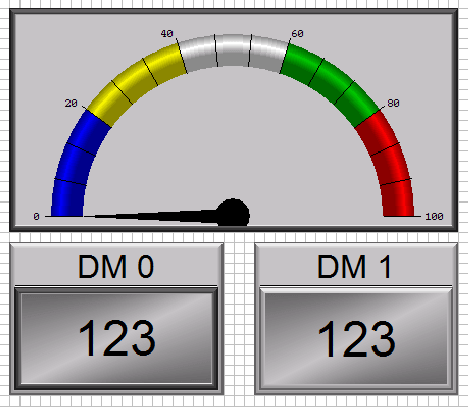

Using the built-in analog on the CPU unit we attach our analog device and then use the scaling instruction. The scaling instruction will take our signal in and convert this to a number between 0 and 100. This will represent the percent on the gauge.

Create an analog voltage input tester for a PLC.

Here are the properties for the gauge display:

Analog Input – DM0 – BCD integer 16-bits

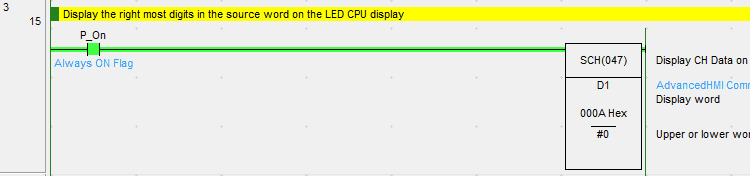

CPU LED Display – Digital Panel Meter

The Omron CP1H has a two-digit LED display that can be used to display information. We use the SCH(047) instruction to display either the upper or lower two digits. In our case, we will be displaying the lower two digits from data memory 1 (D1). The information will be coming from our HMI screen.

See the picture above.

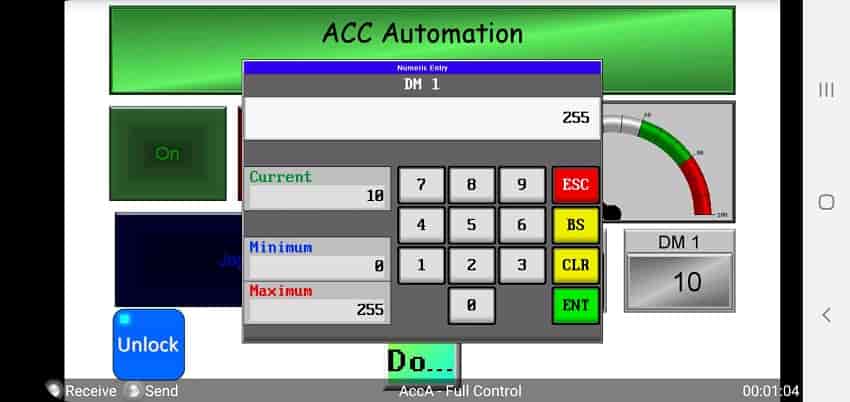

DM1 – DM1 – Unsigned integer 16-bits

The keypad is used to input variables into the PLC.

CMore Programming Software

The entire series of the C-More can be found at the following link.

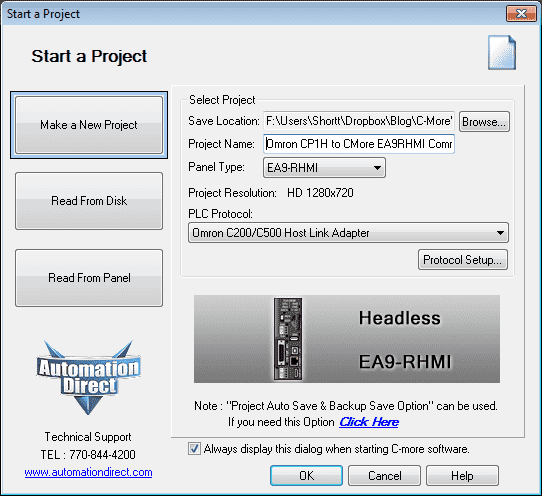

We will start a new project.

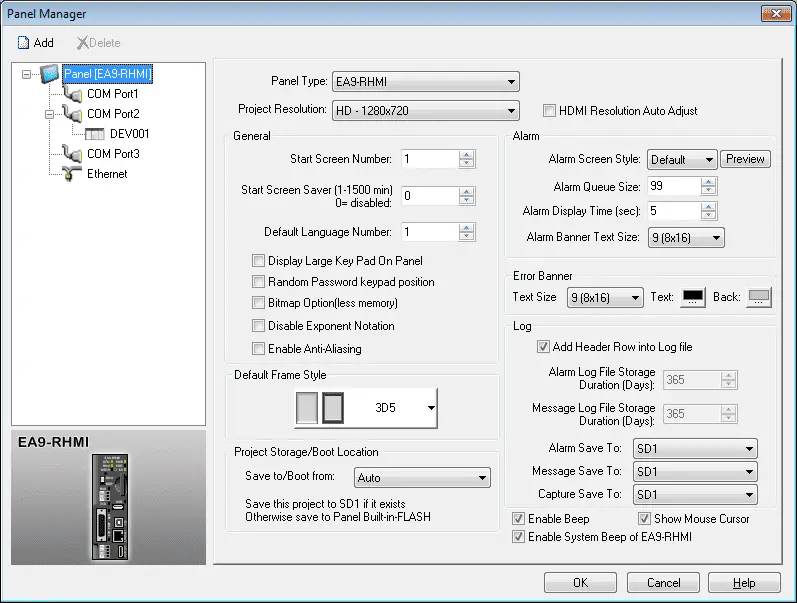

Our panel type will be the EA9-RHMI. This is a headless unit that you can connect a large screen television unit via the HDMI cable. Remote units can include windows, android, and IoS systems. These are available free of charge on the appropriate site.

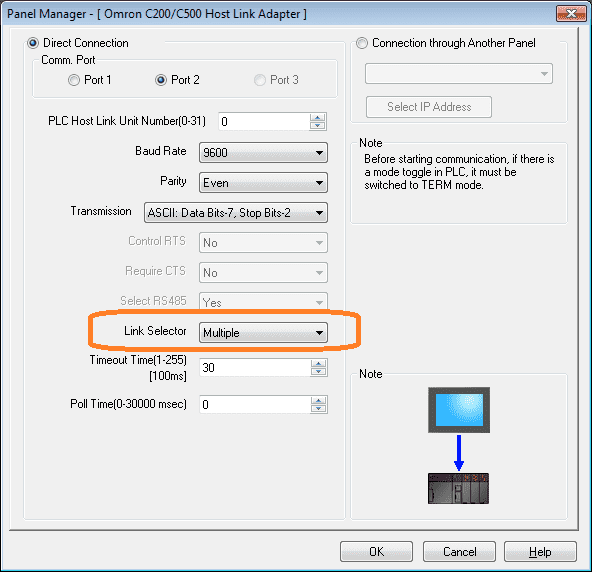

The PLC protocol will be set for the Omron C200/C500 host link adapter. This is a serial type of communication. Select the protocol setup… button.

Port 2 on the unit is select which is the RS485. The baud rate and other serial parameters must match the Omron unit.

Our PLC host link unit number will be left at the default of 0.

The link selector must be set to Multiple. This means that the communication is a one to many (1:N) type. Selecting single will change the protocol to 1:1 and our communication will not work.

Panel Manager

main menu | Setup | Panel Manager…

We can set up the project resolution, log file information, etc. See the links above.

Tag Name Database

Our tag name database is as follows. This was discussed above.

Simulation

The built-in simulation can allow you to visually see how your screen will look and function.

Setting up Remote Access

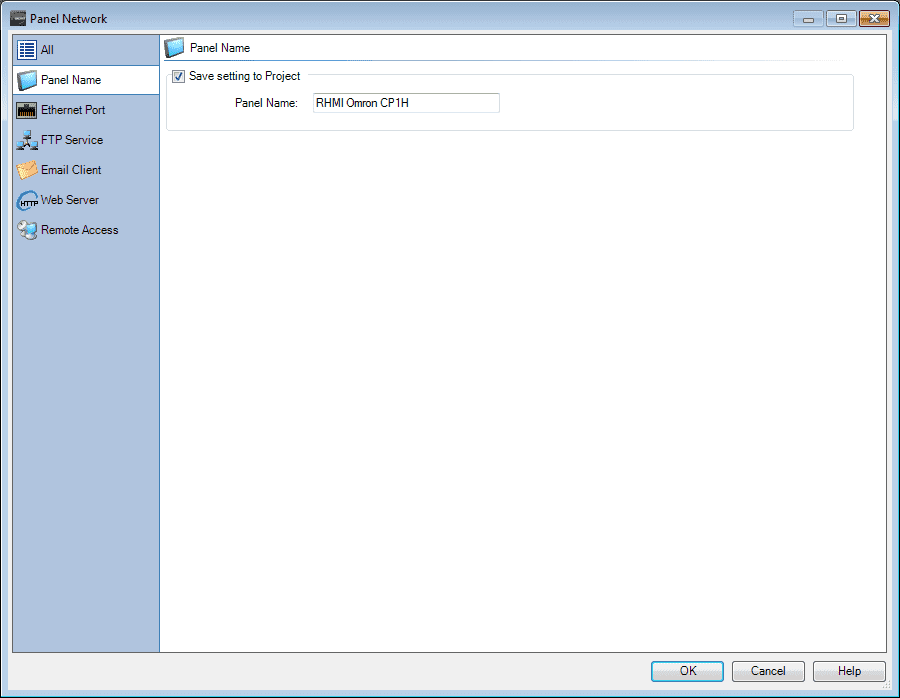

Select panel network from the main menu | setup | panel manager…

Selections are made on the left-hand side.

Our panel can be given a name so we can distinguish this from other panels on the network.

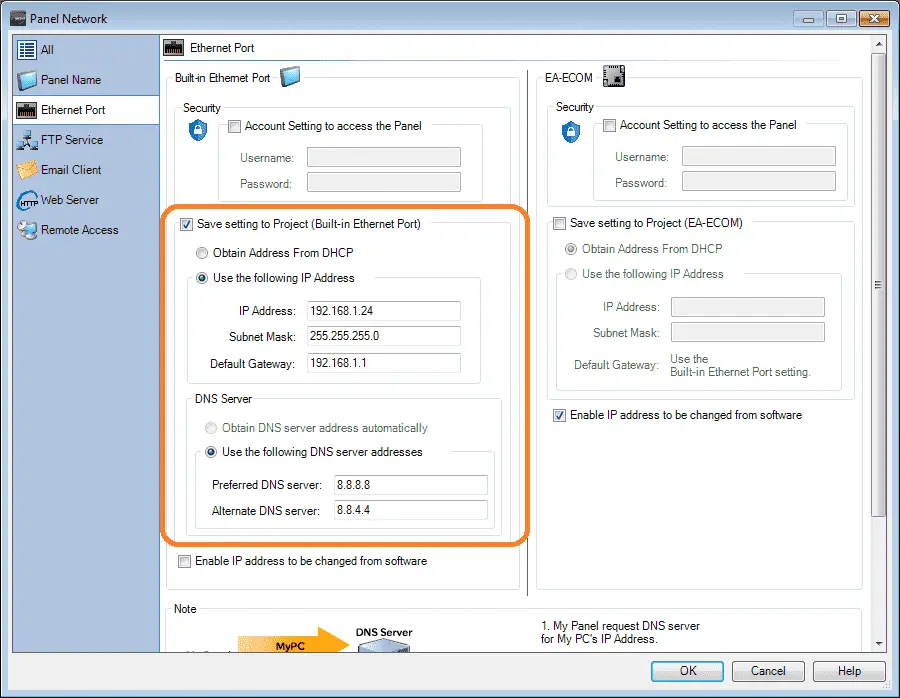

Select the ethernet port.

A static IP address will be used in order to ensure that our remote program can always find our HMI.

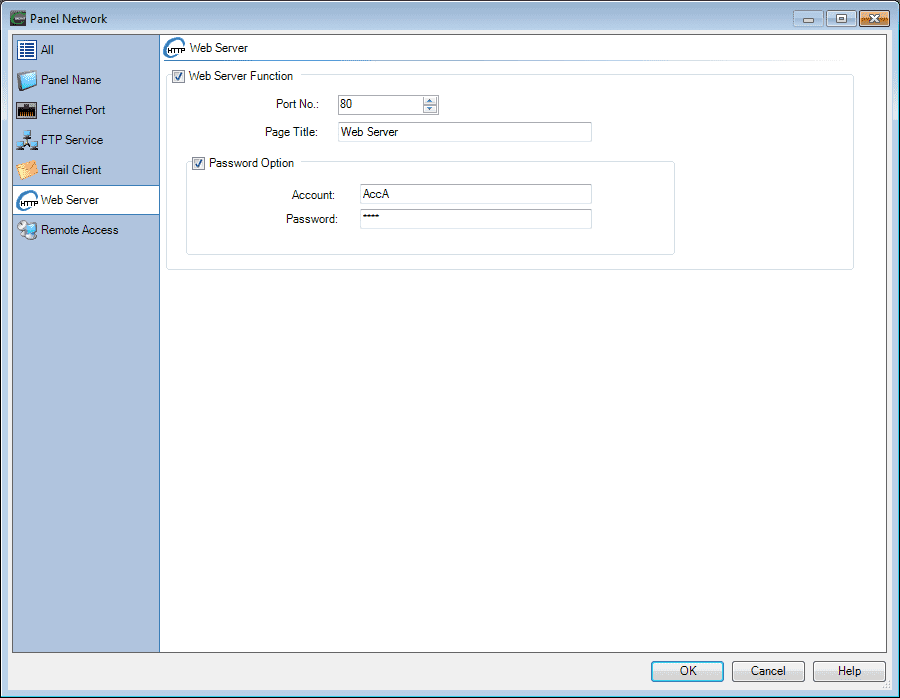

Select the webserver.

The webserver is required to be active to download the windows-based remote program. When this is downloaded into the c-more HMI a browser can be used to call up the internet protocol (IP) address. The executable file can then be downloaded. See the video below.

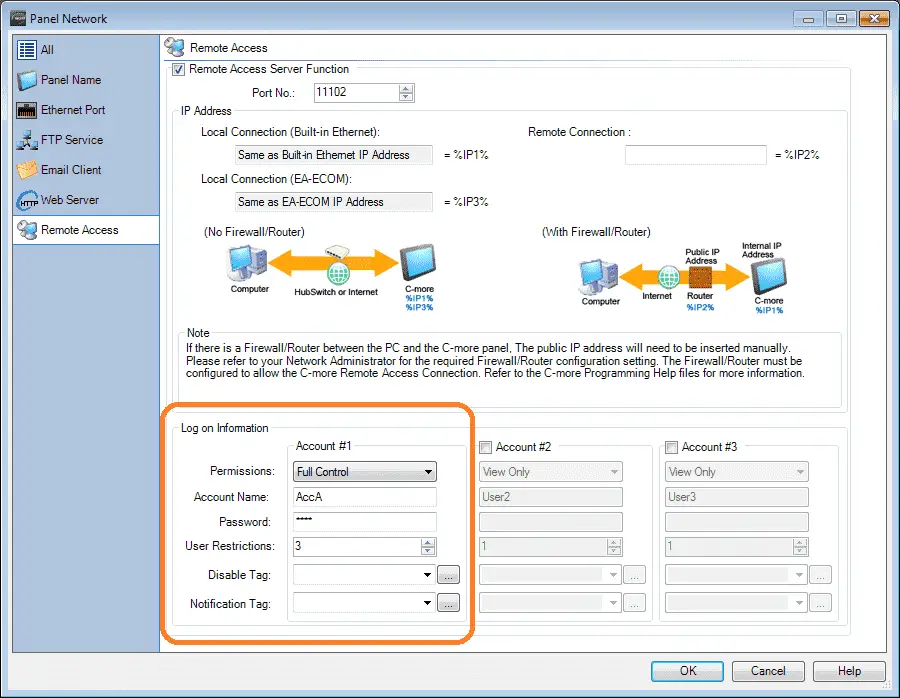

Select remote access.

This is where we will set up the account names and type of access for the remote connections to view or control the HMI.

In our case, we will be using full control and have a maximum of three users using this account at the same time.

Send this program to the HMI by selecting the Send icon button on the top of the programming software.

Testing the program

Using the windows based software we can test our program. Digital inputs and outputs, and channel input and outputs are demonstrated in our example.

Using the android remote HMI application this is what it looks like. Notice that the screens are very similar to each other. The following link will provide additional information.

C-More EA9 HMI Series Panel Web Server and Remote Access.

See the YouTube video below on using the Cmore EA9 headless HMI to communicate to the Omron CP1H PLC.

The following is a list of manuals associated with the CP1H programmable logic controller. See the descriptions for each of these manuals in the first post: Omron CP1H System Hardware

W450 – SYSMAC CP Series CP1H CPU Unit Operation Manual

W451 – SYSMAC CP Series CP1H CPU Unit Programming Manual

W342 – SYSMAC CS/CJ series Communications Commands Reference Manual

W446 – SYSMAC CX-Programmer Ver. 6.1 Operation Manual

W447 – SYSMAC CX-Programmer Ver. 6.1 Operation Manual Function Blocks

W444 – CX-One FA Integrated Tool Package Setup Manual

W445 – CX-Integrator Operation Manual

W344 – CX-Protocol Operation Manual

You can download the PLC and HMI program as discussed above here.

Watch on YouTube: Omron CP1H to C-More EA9-RHMI Communication

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.