Click PLC & AEDES MQTT: What is the Big Deal?

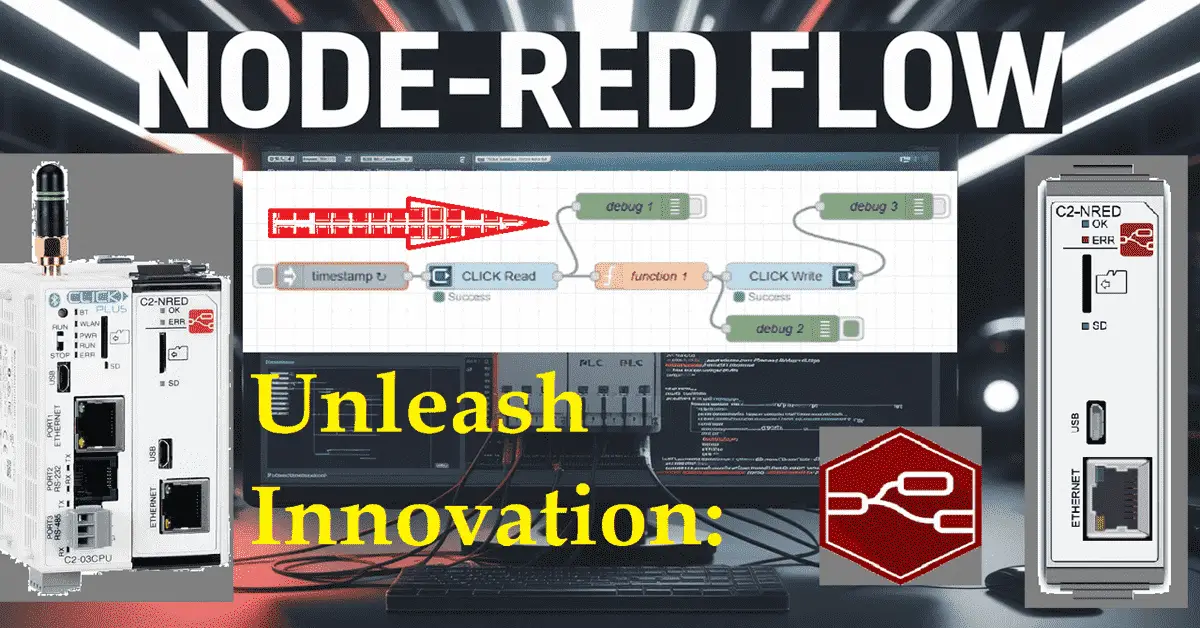

CLICK PLC C2-NRED Aedes MQTT: Revolutionizing Automation CommunicationIn the rapidly evolving world of industrial automation, efficient communication between devices is crucial for the success of any operation. Enter the CLICK PLC C2-NRED with its innovative Aedes MQTT Broker node. This Node-RED node revolutionizes how we perceive automation networking. You can now install an MQTT Broker … Read more