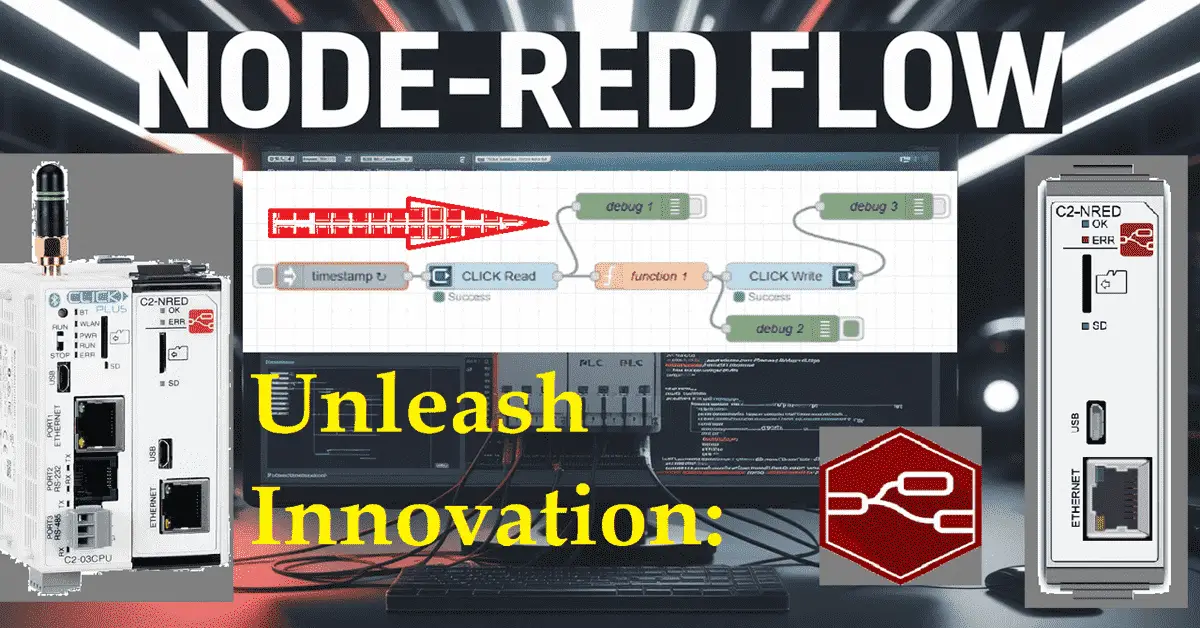

Unleash Innovation: Node-RED Flow in Click PLC

Creating a Node-RED Flow Program in the Click PLUS PLC C2-NRED Module Node-RED is an innovative and powerful tool for connecting hardware devices, APIs, and online services. Regarding industrial automation, the Click PLUS PLC C2-NRED module takes things up a notch by integrating Node-RED, allowing users to create flows via a visual programming interface. Previously, … Read more