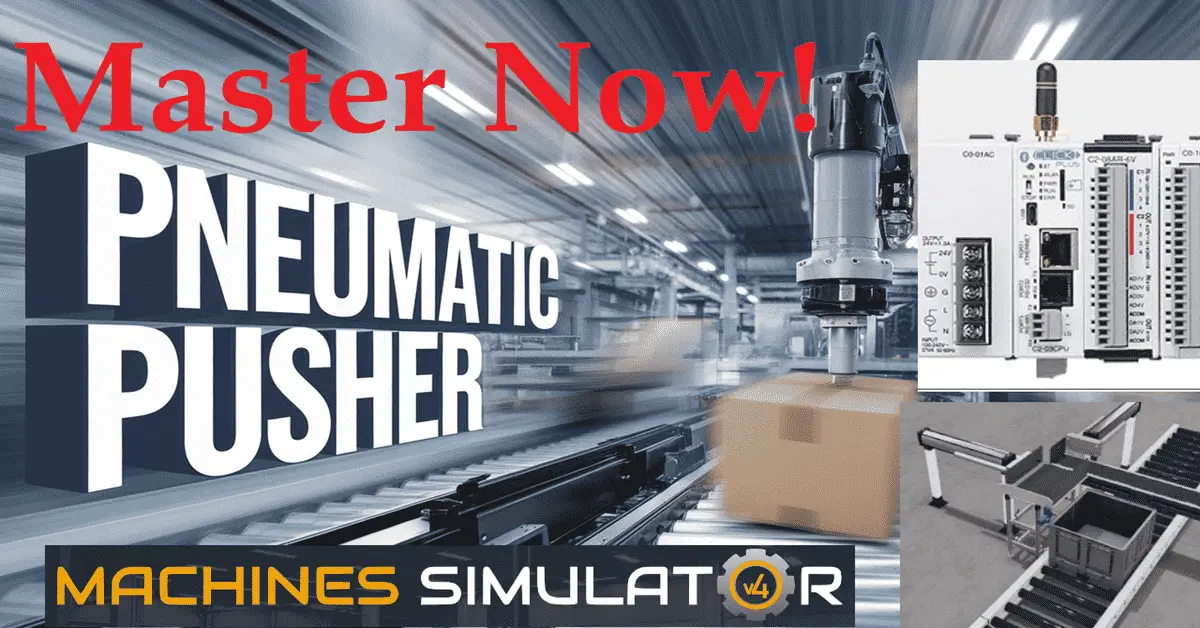

Master the Pneumatic Pusher Simulator Now!

We will now program our Pneumatic Pusher simulator with the Click PLUS PLC. The Machine Simulator (MS) is a valuable component of the Machine Simulator Software Suite. It offers a range of built-in machines, including the pneumatic pusher machine, which effectively demonstrates various programming techniques. We will use the Click PLC programming software to showcase … Read more