We would like to take a few minutes and reflect on the past, current and future of ACC Automation. You have help us succeed in our best year yet.

Starting off we learned how to:

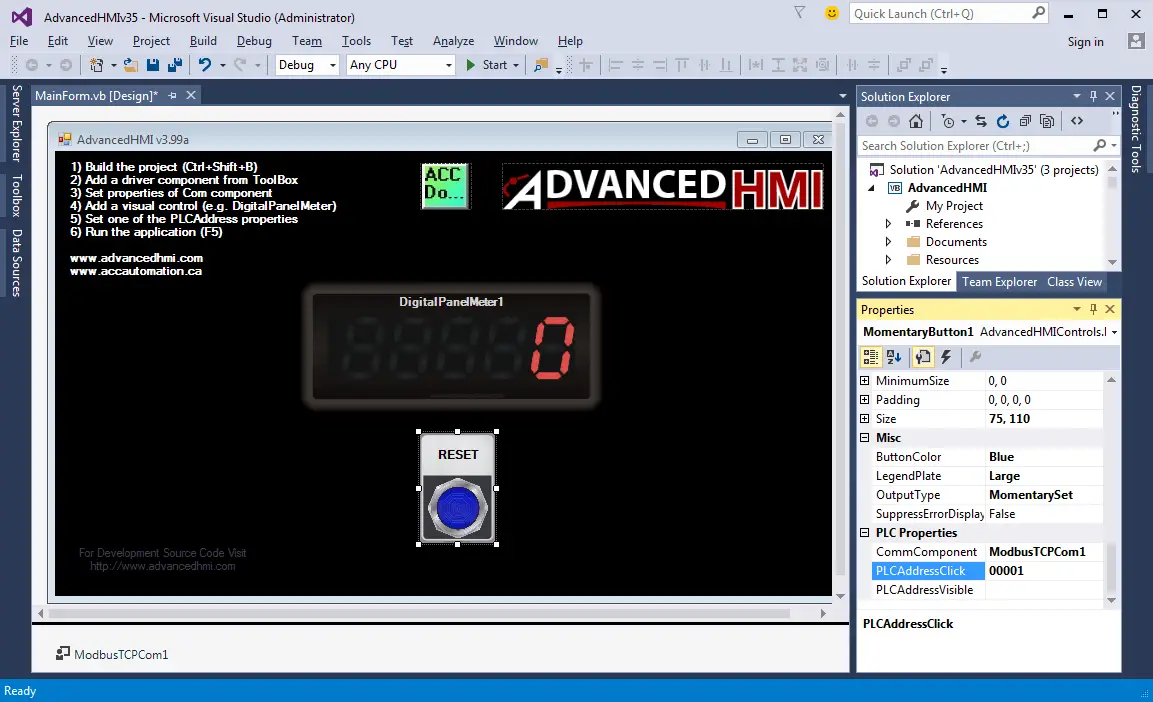

Create a PLC with HMI Training and Learning Environment Free – Utilized the Do-More Designer Software and the AdvancedHMI Software we communicated Modbus TCP to the Do-More simulator. This was all done on one computer without any need for additional hardware. The best thing about this was that the investment was only time learning the packages.

Building a PLC Program that you can be Proud of…

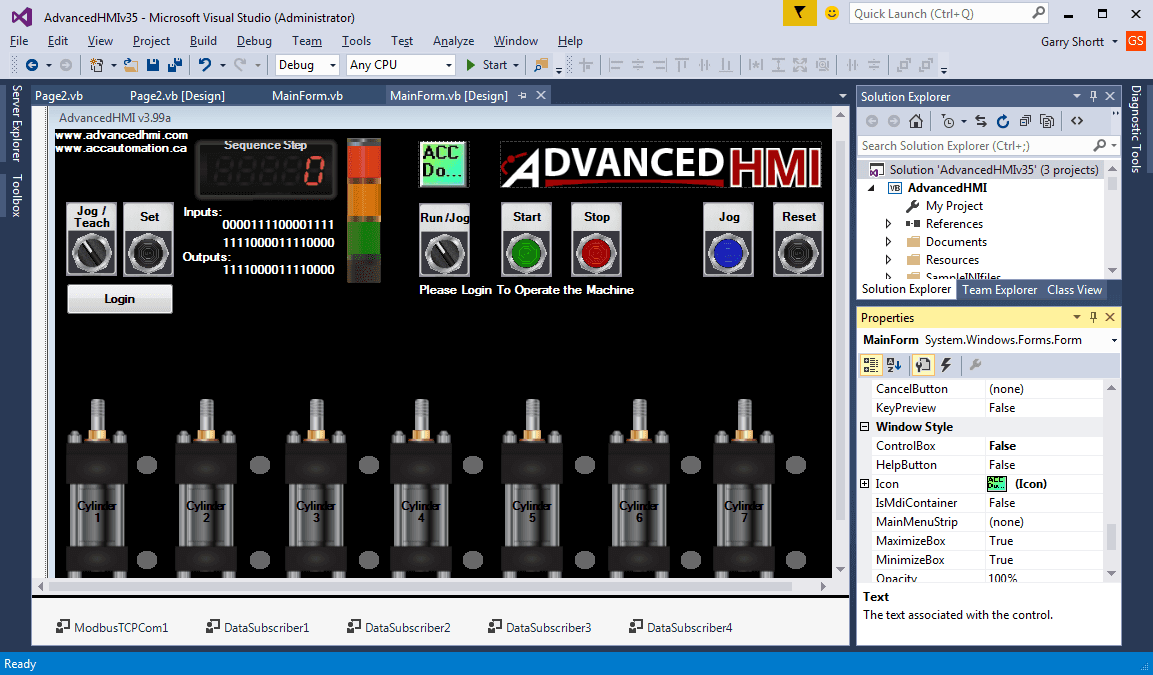

This is by far one of our most popular series. This series takes you through using discrete inputs and outputs to control traffic lights and cylinders. As we progress we introduce additional methods to solve logic. We look at sequencers in a new way and learn how to write programs to allow users to teach the new sequence. We added parts five and six to this series.

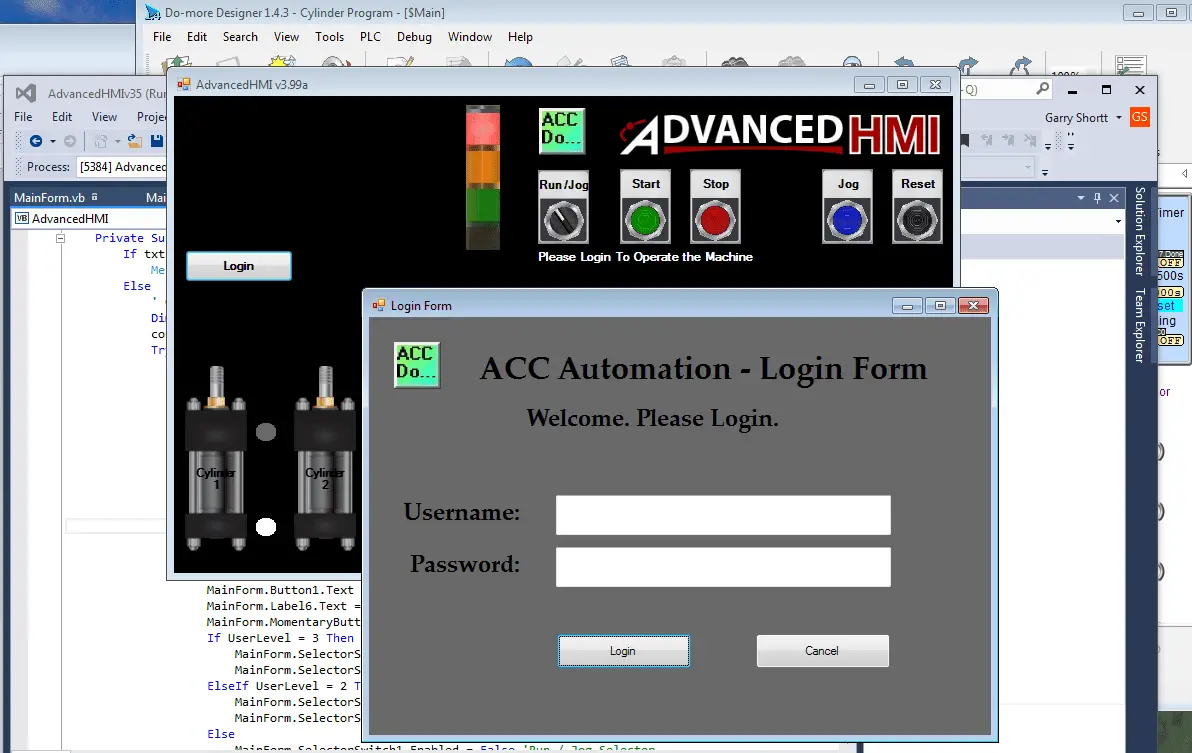

Creating a HMI Login Screen on AdvancedHMI. We cannot say enough about this free programming HMI package. It runs on visual studio and is written in VB.net. Drivers are available for a variety of PLC manufactures and industrial protocols. Give it a try today.

Solo Process Temperature controllers were discussed in detail. We programmed them and communicated to the controller using AdvancedHMI, Click PLC and Horner APG XL4 Controller. This inexpensive adaptable controller is perfect for even the most demanding tasks.

Click PLC Series

Click PLC Video Series

This series will go from examining the hardware to programming and communicating to the PLC in several ways.

Here are just a few advantages of using the Click PLC:

– Investment is low for the hardware and the software is free

– Standalone PLC with built in I/O

– Communication ability – Ethernet Port, RS232, RS485 – support for protocols such as Modbus RTU, Modbus TCP, etc.

– Ability to expand the system with a variety of modules including RTD and Thermocouple inputs directly.

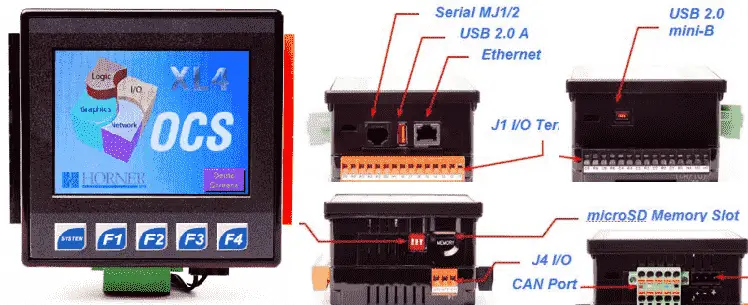

Horner APG XL4 Series

Horner APG XL4 Video Series

This series on the Horner XL4 all-in-one controller (PLC) will go step by step through learning how to use this innovative unit.

There are several reasons why we are using the Horner XL4 Controller. Here are just a few.

– Investment is low for the hardware and the software is free

– Standalone PLC with built in I/O and HMI

– Communication ability – Ethernet Port, RS232, RS485 – support for protocols such as Modbus RTU, Modbus TCP, etc.

– Built in data logging functions

– Ability to expand the system with a variety of modules

Currently we are in the process of this Horner APG XL4 Series. We will continue in the New Year with additional communication and special function of this controller.

Here are three more posts that were done in 2016 that are worth mentioning.

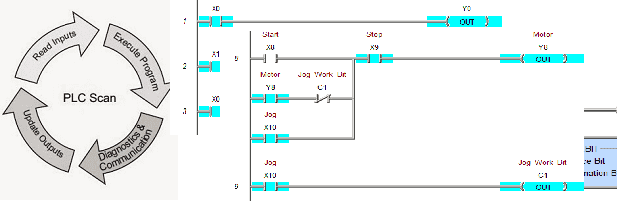

Understanding the PLC Program Scan

Understanding how the PLC will scan and update your program is critical in programming and troubleshooting your system. Typically a PLC will solve your logic from left to right, top to bottom. The status of the memory from the previous rung, are available for the next rung to use. We will look at a few examples to determine how the PLC will solve logic to illustrate the above program scanning.

The 7 Essential Parts of a PLC System

PLC systems today are capable of so much more than in the past. We look at how we can now break up these modern PLC system into the seven essential components.

CPU

Inputs and Outputs (I/O)

Analog I/O

Specialty I/O

Programming Tools

HMI

Networking

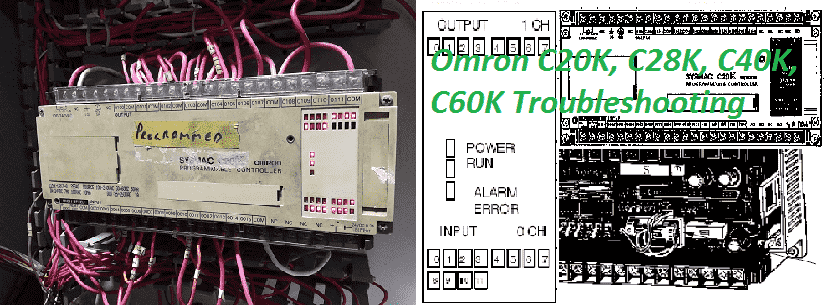

Omron C20K, C28K, C40K and C60K Troubleshooting

The Omron C20K, C28K, C40K and C60K shoebox programmable logic controllers have been discontinued since March of 2002. These ‘K’ series PLCs were a popular controller and have been in installations for over 25 years. We will take a look at this PLC and review some troubleshooting techniques. Planning for the eventual fatal failure of the CPU will also be discussed.

2017 will prove to be an exciting time. We will look at a couple of new series.

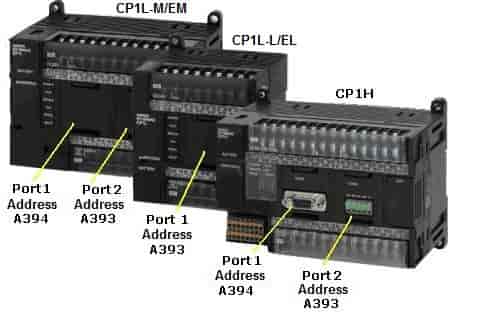

Omron CP Series

Siemens Logo Series

As always we will be answering your questions and applications so you can quickly implement your control solution.

Watch on YouTube : ACC Automation 2016 Review

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.