Accelerate Learning …

Accelerate Machines…

Accelerate Knowledge…

ACC Automation

Each year we like to take a few minutes and reflect on the past, current, and future of ACC Automation. You have helped us build the site you see today through questions, comments, and suggestions. Thank you.

In this Covid-19 world, we are continuing to adapt. Social distancing, mask-wearing, hygiene, etc., are how we live. Video conferencing with Zoom, Teams, and Google Meet is the norm in business today. Information is knowledge, and everyone, more than ever, wants to be able to see, control and summarize production data regularly.

Open, intuitive technologies are available to communicate like never before. Industrial plant data is rapidly changing. Factory 4.0 IoT benefits are being seen, and everyone wants to take advantage.

We look forward to the New Year and new possibilities for implementing your control solution.

ACC Automation – Past 2022 PLC Learning

Starting the year, we looked at a quick start guide for the EasyPLC Software Suite. The EasyPLC Software Suite is a complete PLC, HMI, and Machine Simulator. This quick start aims to help you quickly learn this software suite. It will help you to learn PLC programming.

EasyPLC has had a few updates throughout the year, adding more machines to program and learn.

We continued to add more posts to our PLC learning software EasyPLC. This included how you can modify or design your 3D machine.

We finished our PLC Learning Series by looking at the HMI. This series discussed PLC inputs, outputs, memory, numbering systems, cyclic scan, programming steps, and operator interfaces. A human-machine interface (HMI) is present in some form for every PLC.

The HMI connects a user to a machine system to exchange information or control data. This interaction with the system can be through hardware or software.

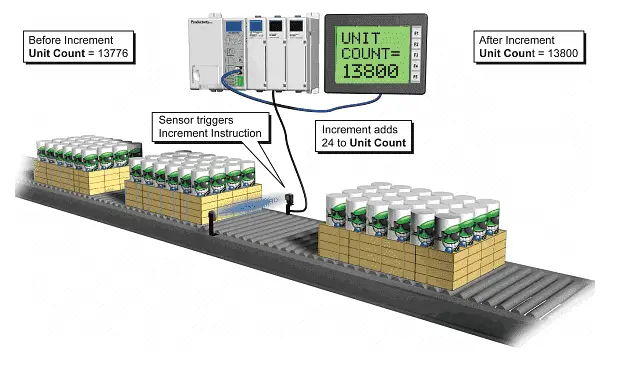

Continuing our series for the Productivity 2000 PLC controller throughout the year, we have discussed installing everything from installing the software to looking at the individual ladder logic instructions.

The BRX Do-More PLC’s firmware update added high-speed inputs and outputs. We looked at how this was implemented.

High-Speed Input Counter

High-Speed Timer

High-Speed Pulse Catch

The BRX Do-More firmware also updated communication on the CPU. A Modbus IO scanner was introduced. This reduces the time it takes to implement the protocol within the PLC. No more writing individual instructions to send and receive communication.

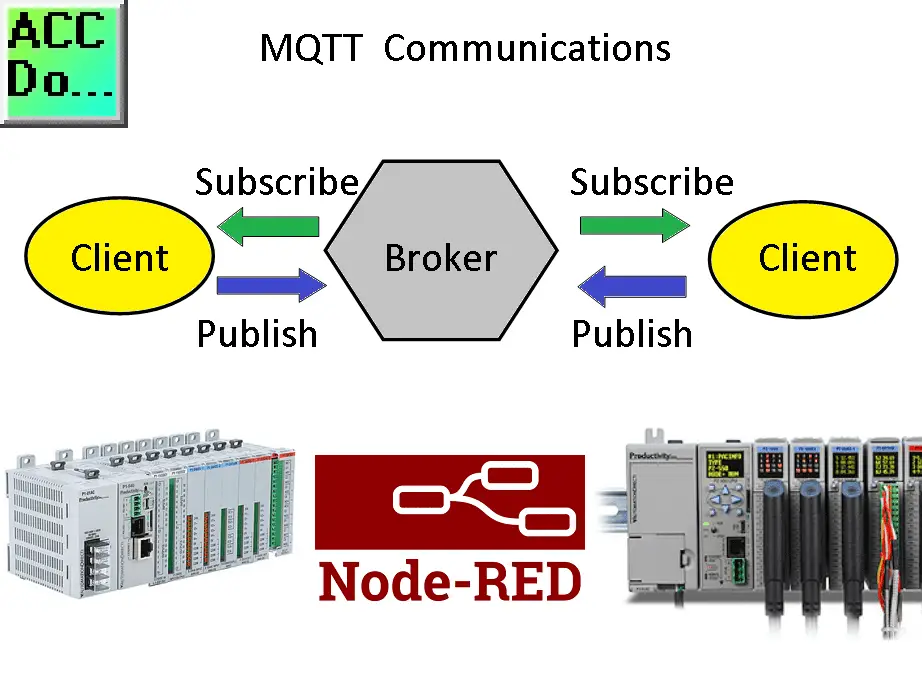

Node-RED is an enabling software for IoT. (Internet of Things)

This means that we can communicate to control and read information from industrial equipment. Logging information into databases and analyzing this information is easily achieved. We explained how Node-RED flows could be done in the following posts and videos.

Productivity PLC – MQTT

Node-RED is part of your Factory 4.0 control solution.

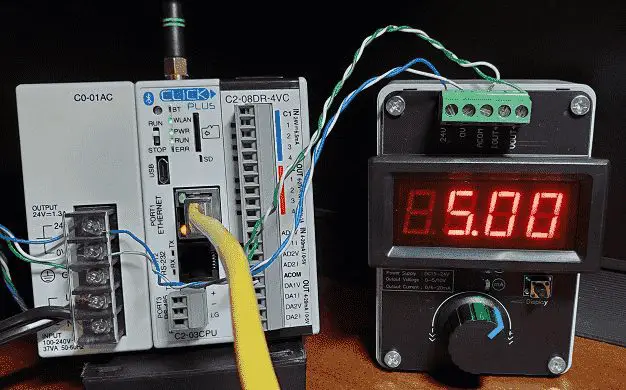

Click to Click PLC communications were discussed.

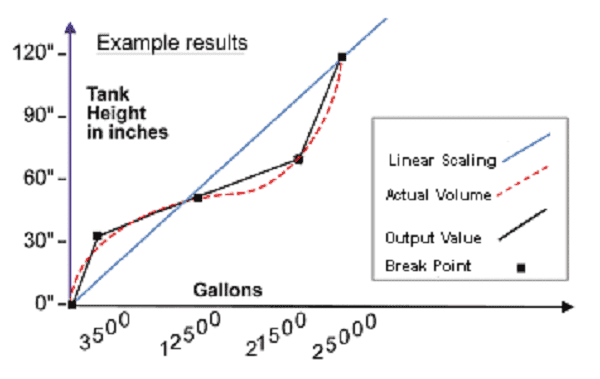

Several other posts throughout the year answered your questions or further explained a feature. The analog input on the Click PLC comes to mind.

This showed how you could use non-linear scaling.

Based on your information from a survey on our YouTube channel, the PLC training series discusses the development of a PLC. The main components of the PLC controller are broken down and explained.

ACC Automation – Current 2022

We are currently in the process of our Productivity 2000 and EasyPLC Software Suite Series.

Through your comments and suggestions, we have updated our website. It is designed to quickly work on any computer, phone, or tablet.

Maneuvering around the website has been simplified, and the right-hand sidebar menu makes subscribing to the website easier. Let me know what you think in the comments below.

Maneuvering around the website has been simplified, and the right-hand sidebar menu makes subscribing to the website easier. Let me know what you think in the comments below.

ACC Automation – Future 2023 PLC Learning

2023 will prove to be an exciting time. We will continue with our two current series with additional examples of 3D simulations of the process. This will be done with the physical PLC hardware and the free PLC simulators from Do-More Designer or Productivity Suite.

Further Node Red flow programming and implementation examples will be demonstrated. This will include discussing the “Data Hub,” “Unified Name Space,” etc.

As always, we will answer your questions and applications so you can quickly implement your control solution.

Watch on YouTube: ACC Automation 2022 Review – PLC Learning

If you have any questions or need further information, don’t hesitate to contact me.

Thank you once again for supporting the website in 2022!

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.