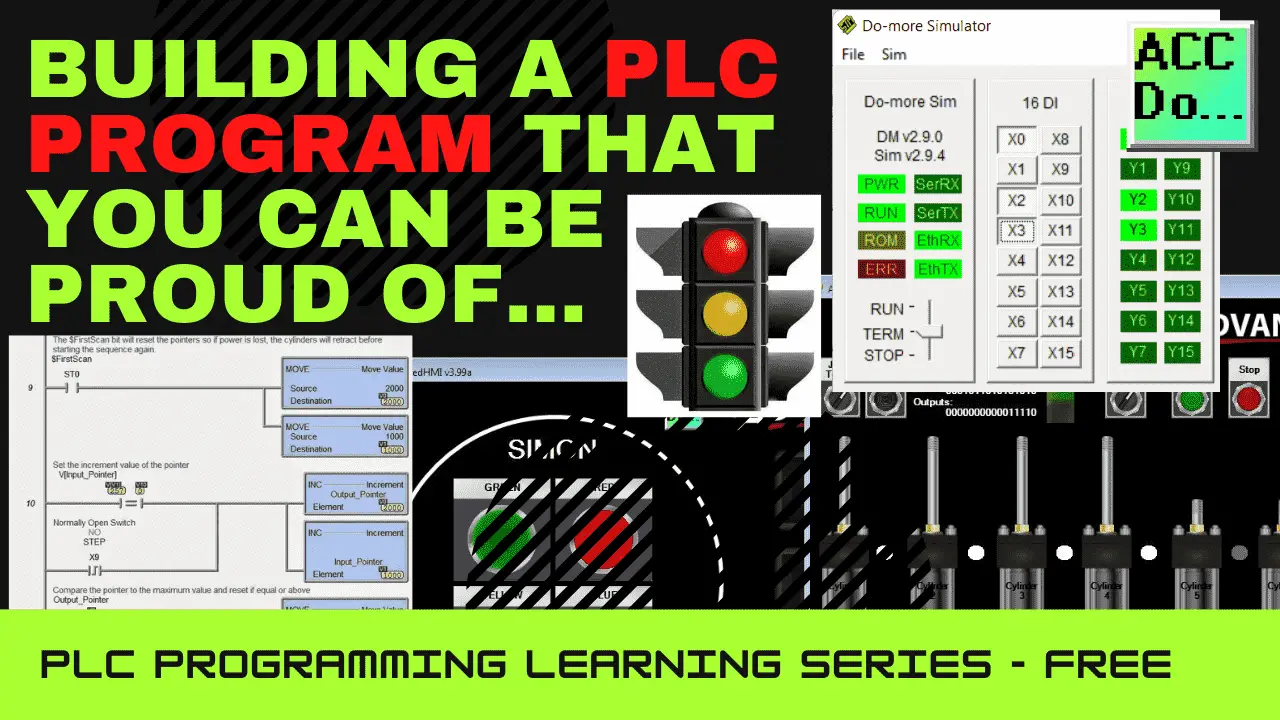

Building a PLC program series will take you through developing and programming PLC logic. This six-part series was released almost seven years ago but is still relevant today. Each part will add and build upon the previous step. This series will look at different ways to solve the same machine logic.

Using discrete inputs and outputs to control traffic lights and cylinders, we progress we introduce additional methods to solve logic. We look at sequencers in a new way and learn how to write programs to allow users to teach the new sequence. This will develop your PLC programming skills. The Do-More Designer programming and AdvancedHMI (VB.Net) software are utilized without purchasing physical hardware. Let’s get started.

Using discrete inputs and outputs to control traffic lights and cylinders, we progress we introduce additional methods to solve logic. We look at sequencers in a new way and learn how to write programs to allow users to teach the new sequence. This will develop your PLC programming skills. The Do-More Designer programming and AdvancedHMI (VB.Net) software are utilized without purchasing physical hardware. Let’s get started.

Part 1 – Traffic Light (Building PLC Program)

Two different programming methods are used, along with three developed programs. The traffic light control example is used because everyone knows how the traffic light is supposed to function. This control of the lights will demonstrate primary input-output and timer control.

Part 2 – Cylinder Control (Building PLC Program)

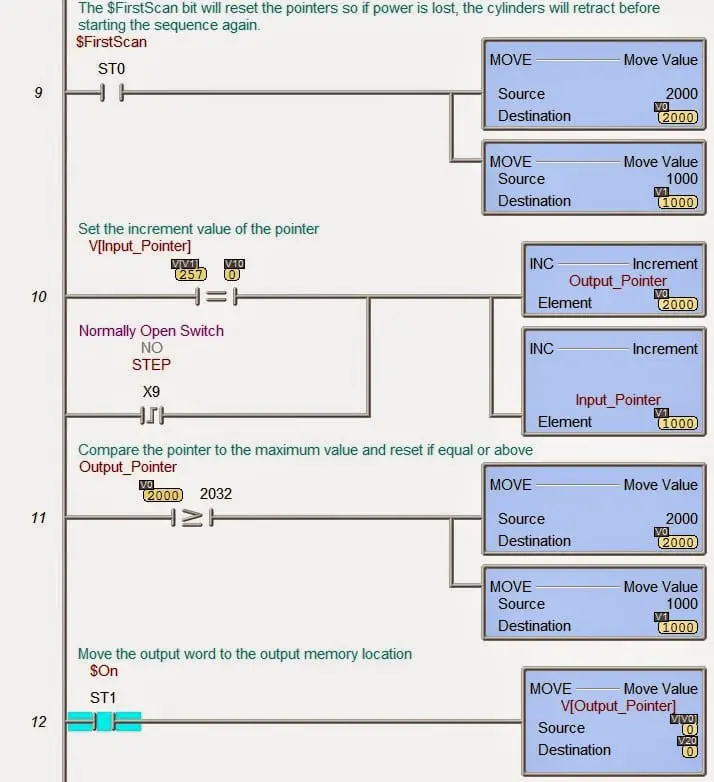

Indirect addressing was introduced with the traffic control example. This was used to set the PLC output lights. Expanding on our control, we will now use indirect addressing to look at the input conditions and set the output conditions for an indirect addressing sequencer.

Part 3 – Traffic Light – Pedestrian and Car Detection

Part 4

Expanding on our traffic light control using indirect addressing, we add pedestrian and car detection to the program. An advanced arrow based on the time of day is also used. This expands the knowledge of sequence control.

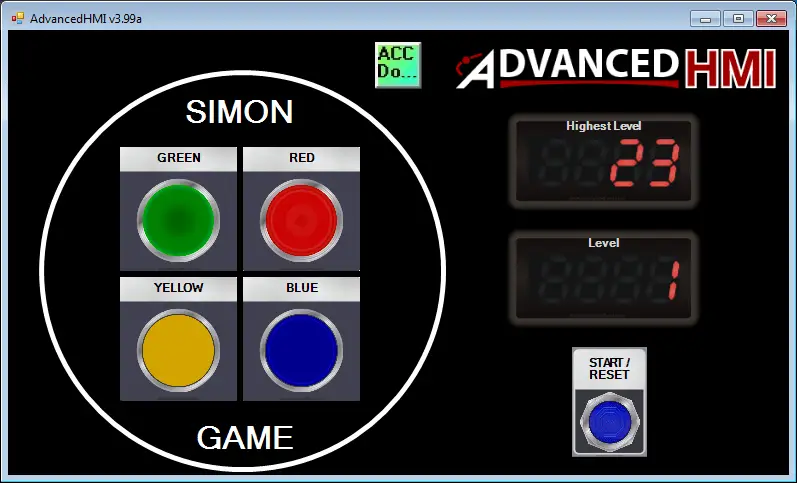

Part 5 – Game of Simon (Building PLC Program)

Using the PLC program simulator and AdvancedHMI (VB.Net), we create the game of Simon. This demonstrates bit manipulation and sequencers. One of the four lights is randomly turned on. The operator (player) must then press the corresponding light input. If it matches, additional random light is added to the sequence. Current levels and high scores are also displayed. This pulls together all the previous posts of the series.

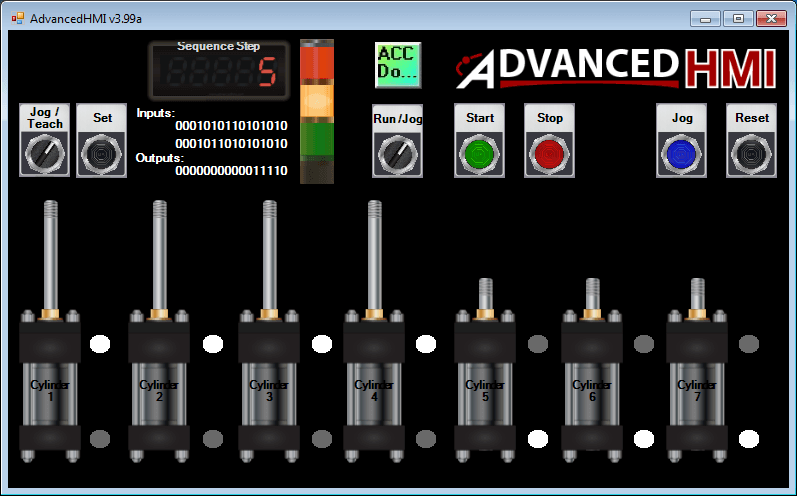

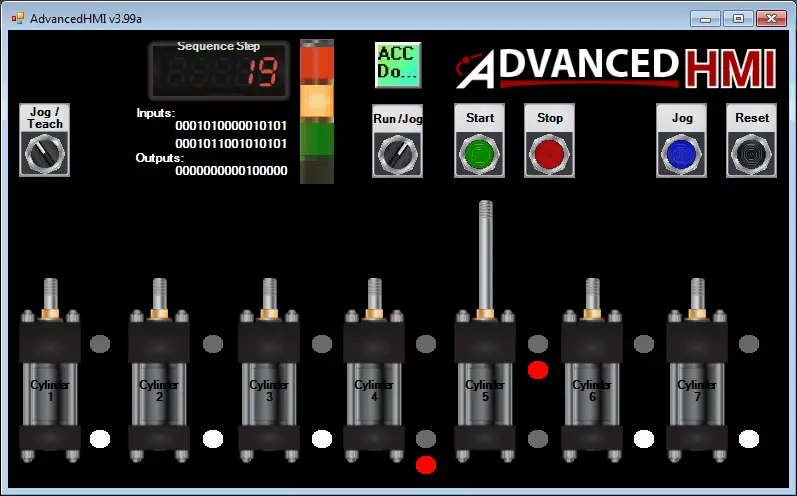

Part 6 – Controlling Seven Cylinders that can be Taught

The seven cylinders can be operator programmed from the AdvancedHMI screen. The operator can select what cylinders to activate at each step and program in 500 degrees. This is then stored as a recipe in the PLC.

Building a PLC program series is an excellent example of ways to think about control.

Free learning and training series for PLCs.

BRX Do-More

Productivity Series

P1000

P2000

Click / Click PLUS (Koyo)

Omron CP1H Series

Horner XL4 Series

EasyPLC Software Suite – 3D training package

Purchase your copy of this learning package for less than $75 USD for a single computer install or less than $100 USD to allow different computers.

Receive 10% off the investment by typing in ACC in the comment section when you order. http://www.nirtec.com/index.php/purchase-price/

Learn PLC programming the easy way. Invest in yourself today.

C-More EA9 Series of HMI

(Webserver, FTP, Data Logging, Free Remote Apps, etc.)

Node-Red is a free IoT software hub that can communicate MQTT and many standard industrial protocols. This series will help you communicate to the PLC, create an HMI on any electronic device, log data to a database, and view the information on a spreadsheet for analysis.

Node-RED IoT enabling software

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, decimals, Hexadecimal, ASCII, and Floating points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.