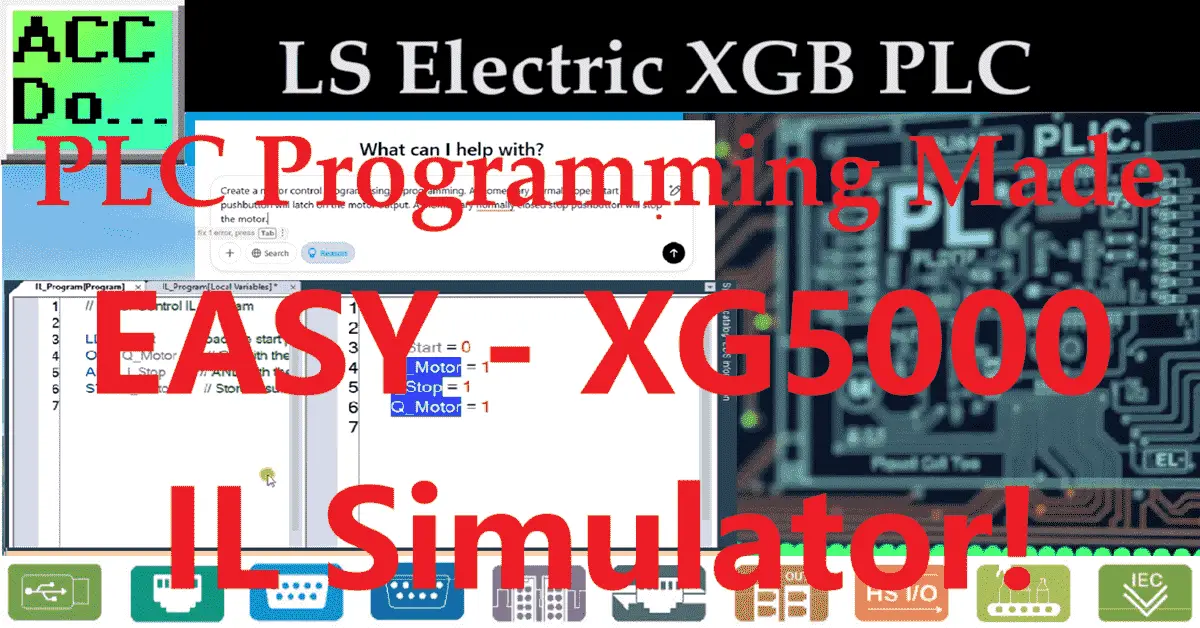

PLC Programming Made EASY – XG5000 IL Simulator!

Learn PLC programming the easy way with the XG5000 IL Simulator! We’ll show you how to simplify your PLC programming tasks and increase productivity. The XG5000 Simulator is part of the XG5000 PLC Programming software. This powerful, completely free tool allows you to test and debug your PLC programs in a virtual environment without physical … Read more