The Productivity Suite Software comprises more than 82 instructions divided into 14 categories. These instructions include NO / NC, NO Edge / NC Edge, and Compare. Contacts are one of these instructions to program your productivity PLC controller. Ladder logic contacts are in every PLC program.

We will be looking at these instructions in the Productivity 2000 series PLC. We will also look at organizing your favorite instructions. This will make them easier to find when programming the productivity PLC. Let’s get started.

We will be looking at these instructions in the Productivity 2000 series PLC. We will also look at organizing your favorite instructions. This will make them easier to find when programming the productivity PLC. Let’s get started.

Previously in this Productivity 2000 series PLC, we have discussed:

P2000 Hardware Features – Video

Productivity Suite Software Install – Video

Communication (System Configuration) – Video

First Program – Video

Debug Mode – Video

PLC Program Documentation – Video

PLC CPU Display – Video

PLC Online Programming – Video

PLC Tag Database – Video

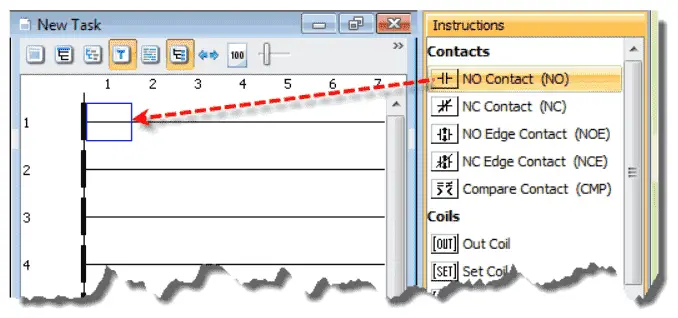

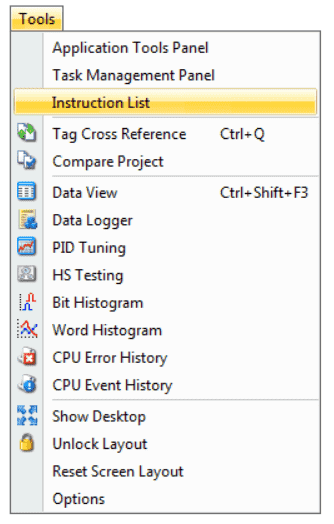

Instruction List

The Instruction List provides access to the programming Instructions for creating ladder logic.

The Instruction List is displayed on the Main Screen and can be placed where desired. If the Instruction List is not shown, it can be accessed from the Tools Menu. Insert an Instruction into the Ladder Editor by clicking and dragging the instruction from the Instruction List to the desired rung position. You can also select the location in the Ladder Editor first and double-click the instruction in the Instruction List. The third way to choose instructions is to select the area on the ladder editor and type in the Mnemonic (Keyboard Shortcut).

The Instruction List is displayed on the Main Screen and can be placed where desired. If the Instruction List is not shown, it can be accessed from the Tools Menu. Insert an Instruction into the Ladder Editor by clicking and dragging the instruction from the Instruction List to the desired rung position. You can also select the location in the Ladder Editor first and double-click the instruction in the Instruction List. The third way to choose instructions is to select the area on the ladder editor and type in the Mnemonic (Keyboard Shortcut).

See the video below to change the location and display of the instruction list.

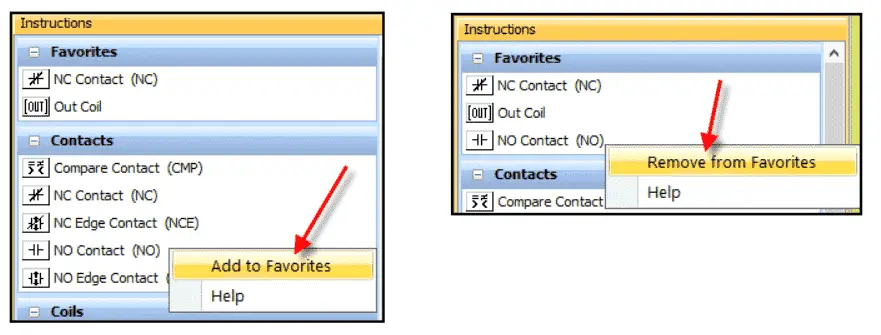

Favorites – Add / Remove

Favorites allow you to add any instruction to your list by right-clicking next to the instruction and selecting Add to favorites. This allows easy access to your most commonly used instructions making programming more accessible.

To Remove an instruction from the Favorites list, you can right-click the instruction and select Remove from Favorites.

To Remove an instruction from the Favorites list, you can right-click the instruction and select Remove from Favorites.

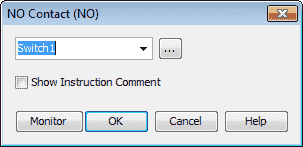

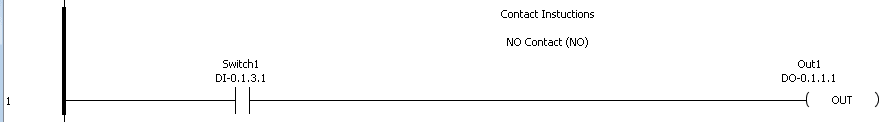

Contacts – NO Contact (NO)

NO Contact (NO) – The normally open contact (NO) enables power flow in a rung when the contact is energized. It disables power flow when contact is de-energized.

Logic is solved left to right, top to bottom on each scan. Here is a post that explains the scanning of the PLC.

Logic is solved left to right, top to bottom on each scan. Here is a post that explains the scanning of the PLC.

Understanding the PLC Program Scan

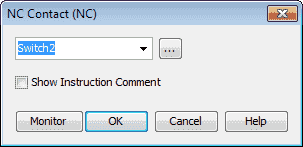

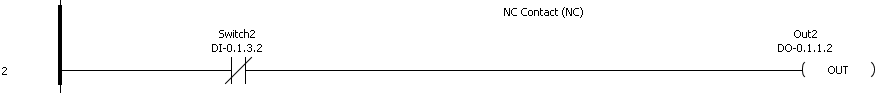

Contacts – NC Contact (NC)

NC Contact (NC) – The normally closed contact (NC) enables power flow in a rung when the contact is de-energized. It disables power flow when contact is energized.

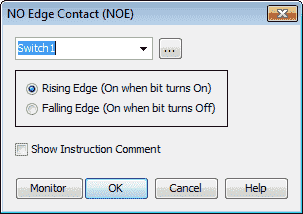

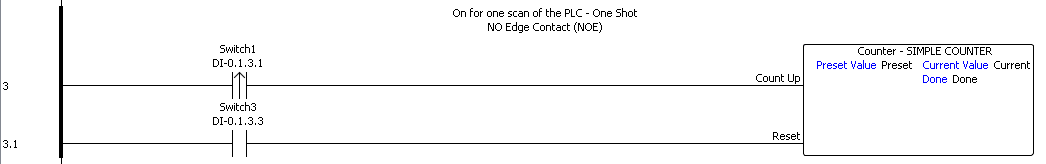

Contacts – NO Edge Contact (NOE)

NO Edge Contact (NOE) – The normally open edge contact acts as a one-shot input on the Rising Edge or Falling Edge signal. It allows power flow for one scan when contact is energized.

This is sometimes referred to as a one-shot in the PLC. Here is a post that discusses the one-shot logic using just a bit of logic.

This is sometimes referred to as a one-shot in the PLC. Here is a post that discusses the one-shot logic using just a bit of logic.

How to make a one-shot in the PLC

Contacts – NC Edge Contact (NCE)

NC Edge Contact (NCE) – The normally closed edge contact acts as a one-shot input on the Rising Edge or Falling Edge signal. It allows power flow for one scan when contact is de-energized.

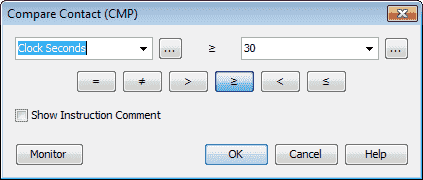

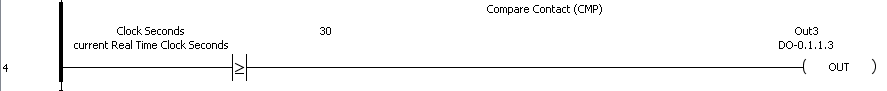

Contacts – Compare Contact (CMP)

Compare Contact (CMP) – This input contact compares two numerical values and, according to a selected operand, enables or disables power flow in the rung based on the result of the operand.

In the example above, if the real-time clock seconds are greater than or equal to 30, the output Out3 will be on.

In the example above, if the real-time clock seconds are greater than or equal to 30, the output Out3 will be on.

Watch the video below to see the contact instructions in our Productivity 2000 Series PLC.

Download the Productivity 2000 PLC ladder logic program here.

Productivity 2000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Overview (Features of the fully functional free software package for the Productivity Family of PLC (PAC) controllers)

Productivity Suite Programming Software (Free Download Link)

This software contains all the instructions and helps files for the Productivity Series.

Watch on YouTube: Productivity 2000 PLC Ladder Logic Contacts

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII, and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.