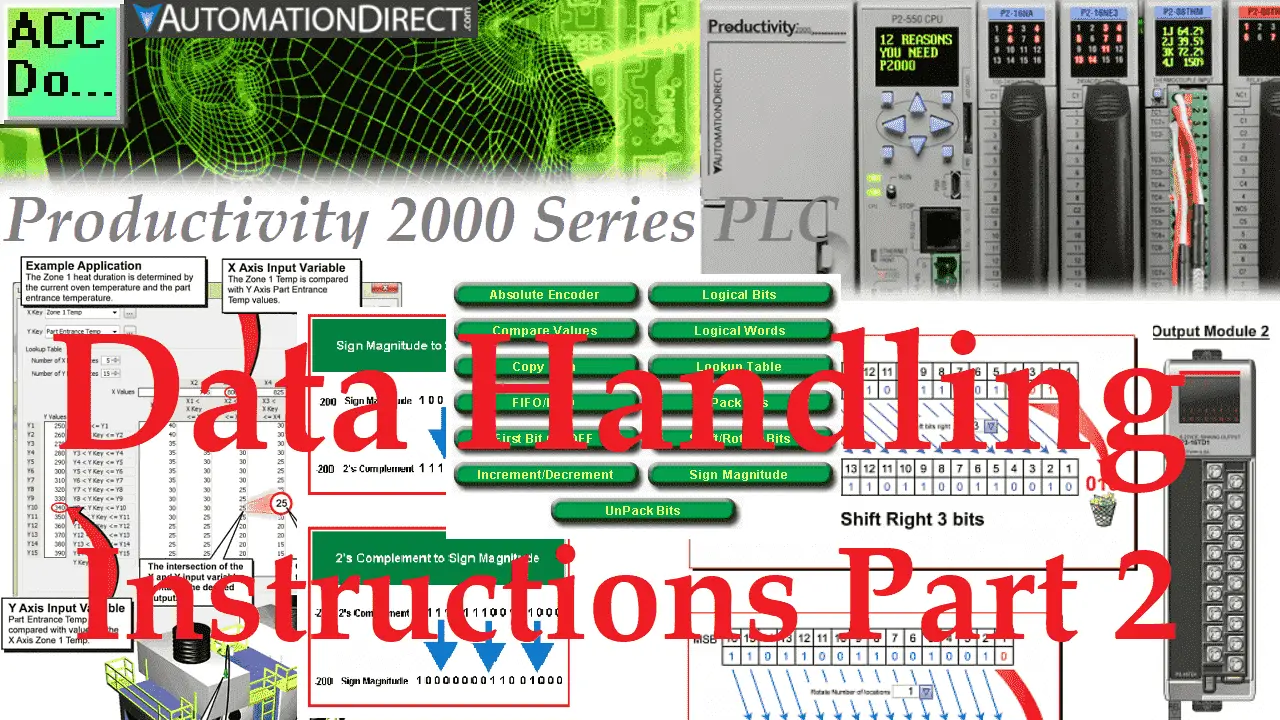

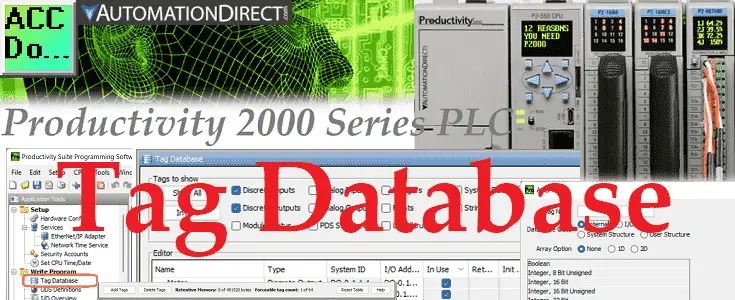

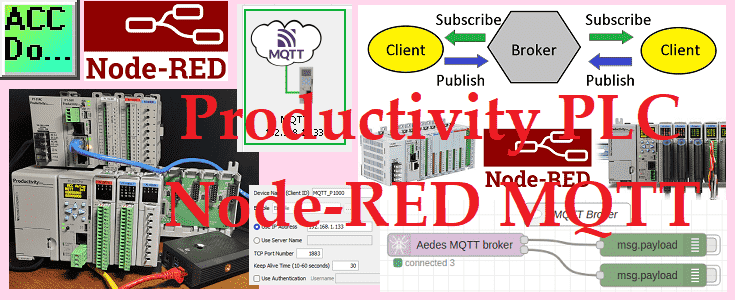

Productivity 2000 PLC Data Handling Part 2

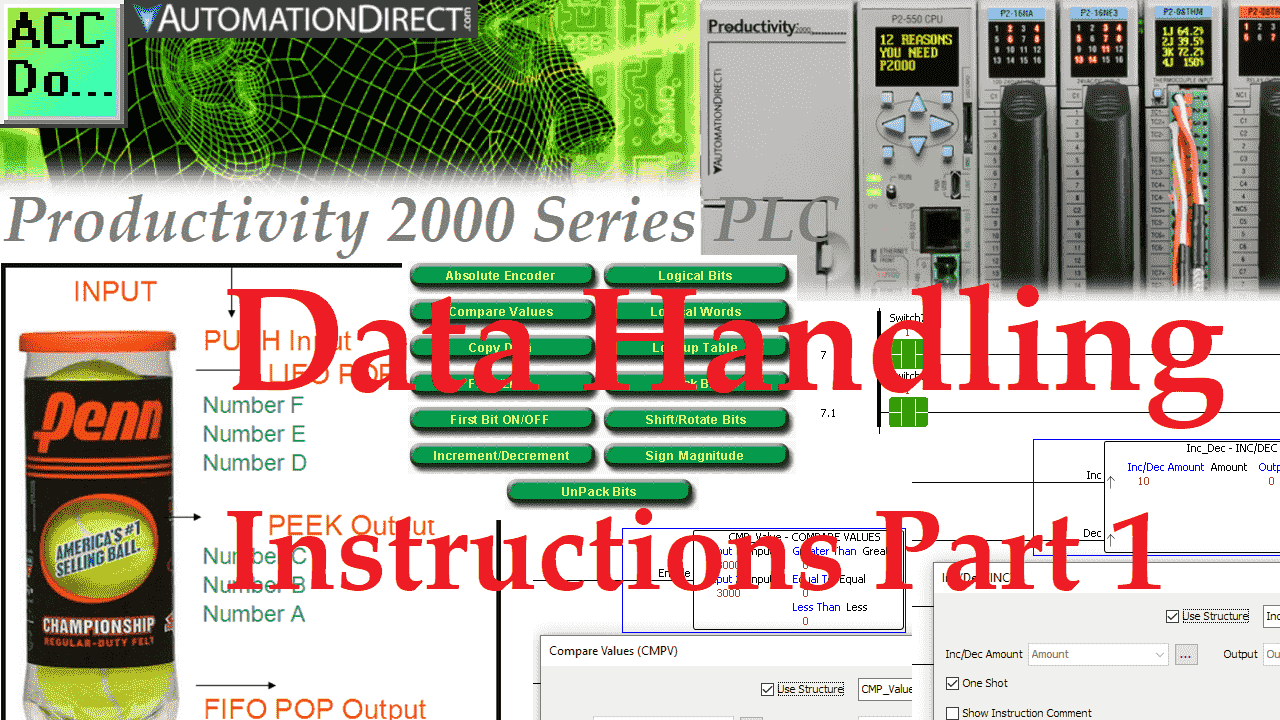

Data handling instructions are used to perform movement and manipulations of the memory in the programmable logic controller. The Productivity 2000 Series PLC has fifteen different data handling instructions that can be used in various applications. This includes all of the data handling instructions. Understanding the full capability of the PLC that you are programming … Read more