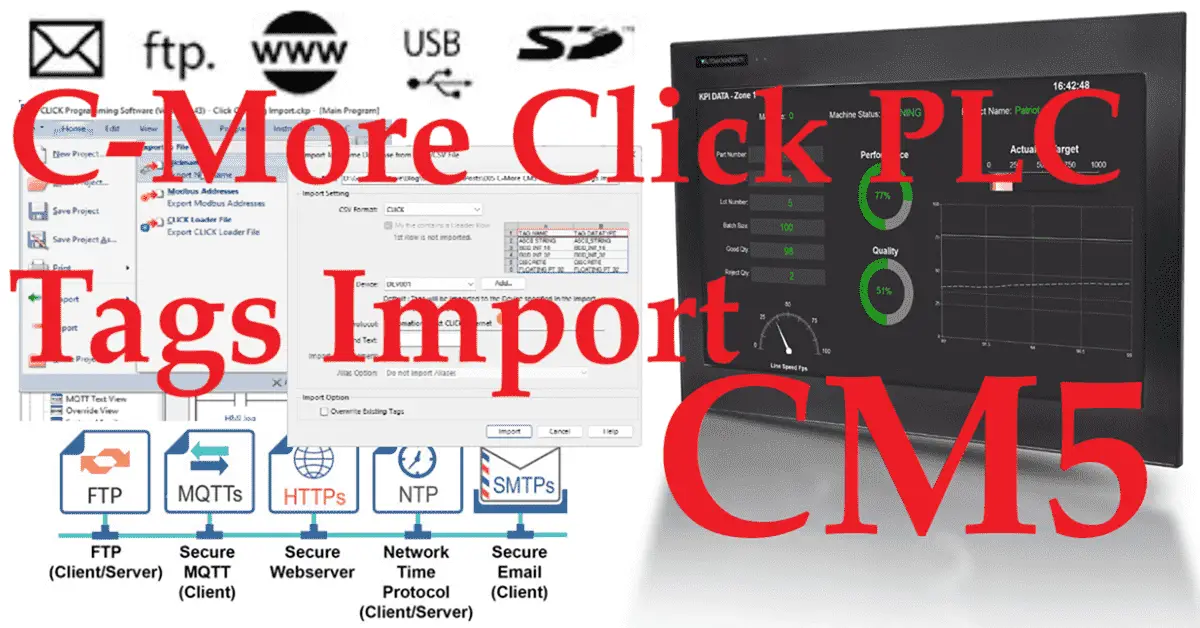

C-More CM5 HMI Click PLC Tags Import

The C-More CM5 HMI programming software will allow tags to be imported. This can save you hours of work when establishing communications with different PLC controllers. Instead of creating and labeling tags in the PLC and the HMI, we can export them from the PLC and import them into the HMI. This saves you time, … Read more