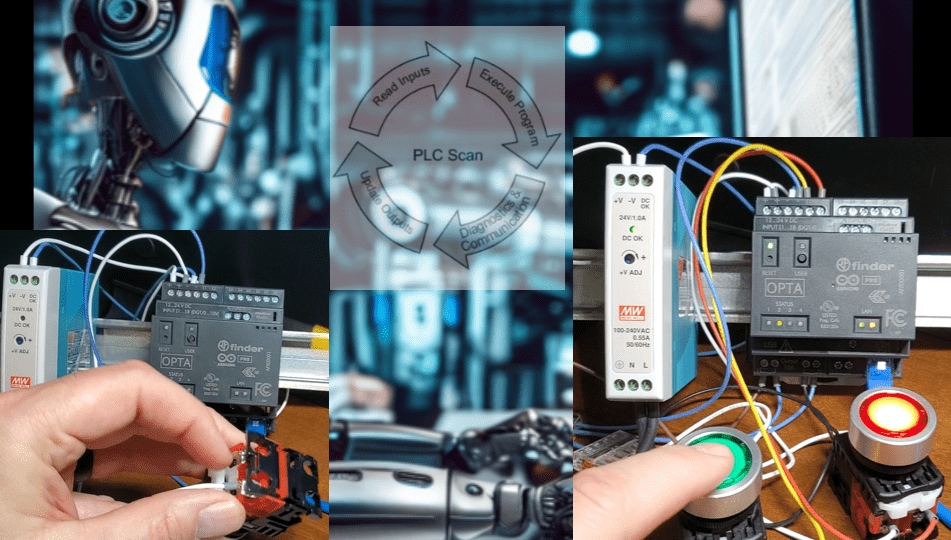

The most commonly asked question is, “What is a PLC?”. A Programmable Logic Controller (PLC) is a computer used to control industrial processes and machinery. It is designed to receive input signals from various sensors, process the information, and then send output signals to handle multiple machines and processes in real time.

PLCs are widely used in industrial automation to control everything from simple machinery to complex production lines.

PLCs (Programmable Logic Controllers) provide a variety of advantages in automation projects:

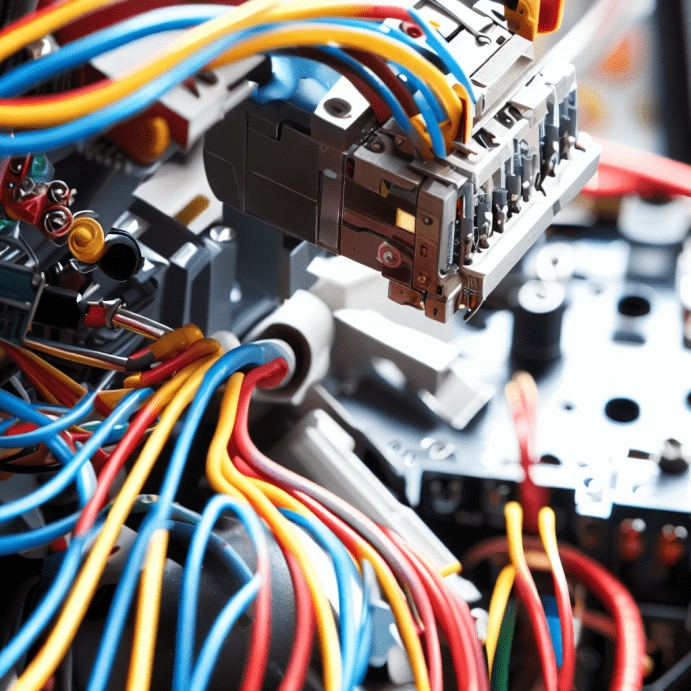

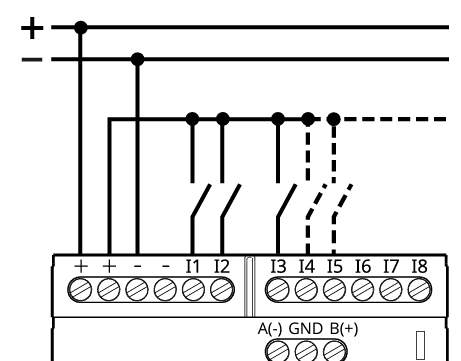

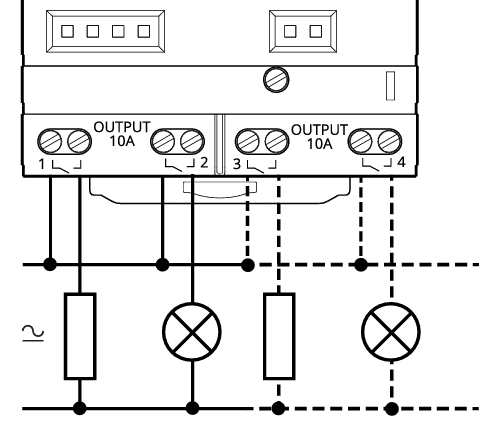

Wiring Programmable Logic Controllers

When it comes to wiring, the traditional approach can be complex and use bulky wiring that may result in loose connections and wiring errors.

However, a PLC programmable logic controller can simplify the wiring diagram for each input and output, reducing the risk of loose connections and wiring errors. This streamlined approach makes the overall wiring process more efficient and time-saving.

PLC programmable logic controller inputs and outputs are isolated, usually through photodiodes, which only share light. In case of a voltage surge, troubleshooting is limited to the individual input or output circuit, making it easier and more convenient. PLC wiring can save time and reduce the costs of installing and maintaining complex wiring systems by eliminating the need for multiple wires. Moreover, using a PLC programmable logic controller can improve the overall safety of the wiring system by minimizing the points of failure and potential hazards. This, in turn, reduces the cost of installation enclosures as they become smaller and more compact. Watch the video below to see the wiring of the PLC in action.

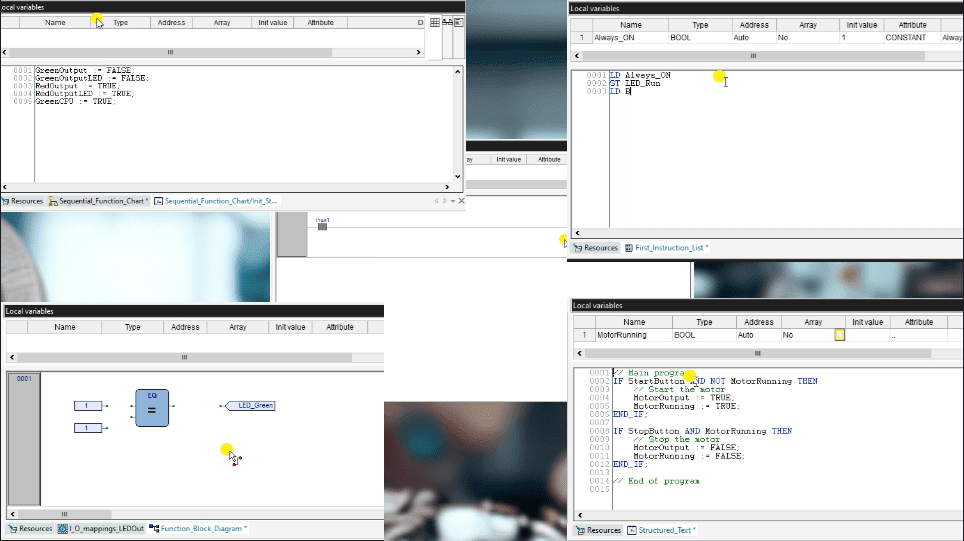

Programming Programmable Logic Controllers

Programmable Logic Controllers (PLCs) are highly flexible and adaptable devices used in various automation processes. They allow easy and efficient control logic modification without laborious and time-consuming rewiring procedures. PLCs can be quickly reprogrammed to suit the specific needs of the process environment, making them an invaluable asset for industries that require agile and dynamic modifications to their automation systems.

Recently, an attempt has been made to standardize different program languages, resulting in five PLC languages: Ladder Logic, Structured Text, Instruction List, Sequential Function Chart, and Function Block Diagram. This flexibility of the PLC programming environment allows you to adapt the PLC programming package to your specific application. However, it is essential to note that the PLC programming software is mostly manufacturer-dependent. This means that you need to purchase or download the programming software for the maker and model of your PLC. Watch the video below to demonstrate the five PLC programming languages.

Though Codesys is a software package that standardizes the PLC programming environment, not all manufacturers agree with adopting this method. Apart from the actual programming of the controller, features of PLC programming usually include documentation stored on the PLC, online editing of the logic, and monitoring (display and force) variables in the PLC.

PLCs provide a cost-effective solution to automation systems that require frequent upgrades or changes, as the investment in rewiring is eliminated. Therefore, they are an ideal option for industries that require flexibility and adaptability in their automation processes.

Troubleshooting Programmable Logic Controllers

Programmable Logic Controllers (PLCs) are specialized computer systems widely used in industrial automation and control processes. These systems are equipped with various built-in diagnostic tools that can assist in identifying and resolving any issues that may arise during the automation process. The diagnostic tools include features such as error logging, fault detection, diagnostic routines, and LED lights that can help pinpoint the source of any problems in the system. Engineers and technicians can quickly identify and solve problems using these diagnostic tools, reducing downtime and increasing the system’s efficiency.

Moreover, these tools can help prevent issues from occurring in the first place by providing real-time monitoring and feedback on the system’s performance. This enables proactive maintenance and troubleshooting, improving the system’s reliability and efficiency. Overall, the built-in diagnostic tools in programmable logic controllers are critical to any automation system. They provide essential support in ensuring the system runs smoothly and without interruption, contributing significantly to overall efficiency and productivity.

Watch the video below to see “What is a PLC?”.

PLCs or Programmable Logic Controllers offer several benefits. They are highly reliable, fast, and easy to program or reprogram. Moreover, they are designed to operate in harsh industrial environments, capable of withstanding high temperatures, humidity, and vibrations. Since they are programmable, they can be easily modified to adapt to changing production requirements or to add new machines or processes. This makes them an ideal option to improve manufacturing processes’ efficiency and productivity while reducing downtime and maintenance costs.

Watch on YouTube: What is a PLC? (Programmable Logic Controller)

PLC Beginner’s Guide to PLC Programming

There are many different PLC manufacturers with other hardware and software. All of the programmable logic controllers have similar basic features. Here is how I would approach learning about basic PLCs.

Once you are familiar with the basics of the PLC, you will then learn specifics for the controller you will be programming.

This is the easiest way to learn about PLC programming.

Here are the controllers that we have covered or are covering at ACC Automation:

Arduino Opta PLC

BRX Do-More Series (Do-More Designer Software + Simulator)

Productivity Series P1000 / P2000

Click PLC Series

Omron CP1H Series

Horner XL4 PLC Series

EasyPLC Software Suite is a complete PLC, HMI, and Machine Simulator Software package. See below to receive 10% off this software. This PLC learning package includes the following:

Easy PLC – PLC Simulation will allow programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using the EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train, or practice your PLC programming.

Purchase your copy of this learning package for less than $95 USD for a single computer install or less than $110 USD to allow different computers.

Receive 10% off the investment by typing in ACC in the comment section when you order.

Learn PLC programming the easy way. Invest in yourself today.

Additional examples of PLC program development using the five steps.

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Five Steps to PLC Program Development – Die Stamping

PLC Programming Example – Process Mixer

PLC Programming Example – Shift Register (Conveyor Reject)

PLC Programming Example – Paint Spraying

PLC Programming Example – Delay Starting of 7 Motors

PLC Programming Example – Pick and Place

PLC Programming Example – Sorting Station (Shift Register)

PLC Programming Example – Palletizer

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.