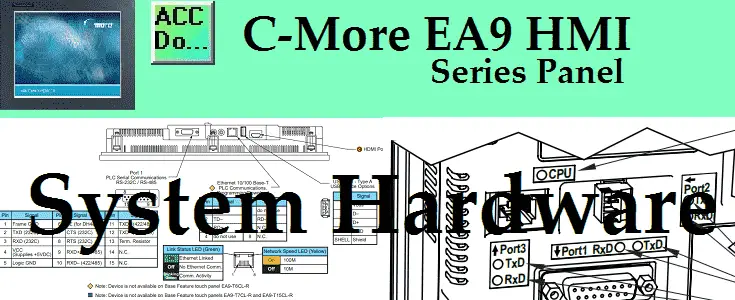

C-More EA9 HMI Series Panel System Hardware

We will now look at the C-More EA9 system hardware. This will include unboxing and powering up our C-More unit. Human-machine interfaces (HMI) are made to display and control operations for our automation solution. Information is displayed in a graphics format. (Graphical User Interface – GUI) The HMI is usually part of the SCADA (Supervisory … Read more