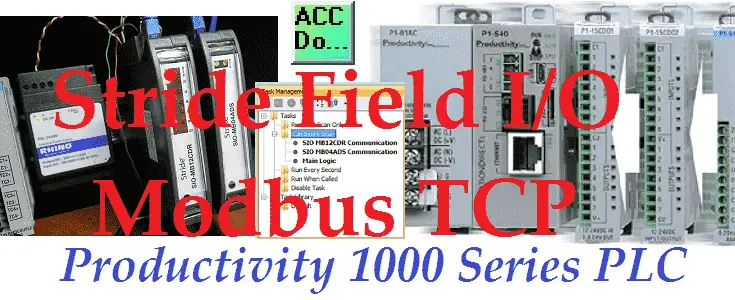

BRX Do-More PLC to Stride Field IO Modbus TCP

We will now look at the BRX Do-More PLC Modbus TCP remote io using Stride Field io. The BRX Do-More PLC can use remote inputs and outputs from Stride. The Stride Field I/O Modules are simple and compact. They provide an economical means to connect inputs and outputs to an Ethernet Modbus TCP communication network. … Read more