Over the past year, ACC Automation has continued to provide valuable content on PLC learning and industrial control. In 2023, the focus continued with PLC learning with minimum investment. Each year, we like to reflect on the past, present, and future of ACC Automation. The site has been built with the help of its audience, and the content has aimed to provide knowledge and insights into production data and control. Thank you!

The YouTube channel and website both emphasize learning industrial control and provide different media for this learning. The past year has seen a continued commitment to providing relevant and informative content in industrial automation and control. Thank you again for your continued support of ACC Automation. We look forward to the New Year and new possibilities for implementing your control solution.

Past… ACC Automation 2023

Over the past 12 months, ACC Automation has covered some of the following detailed topics:

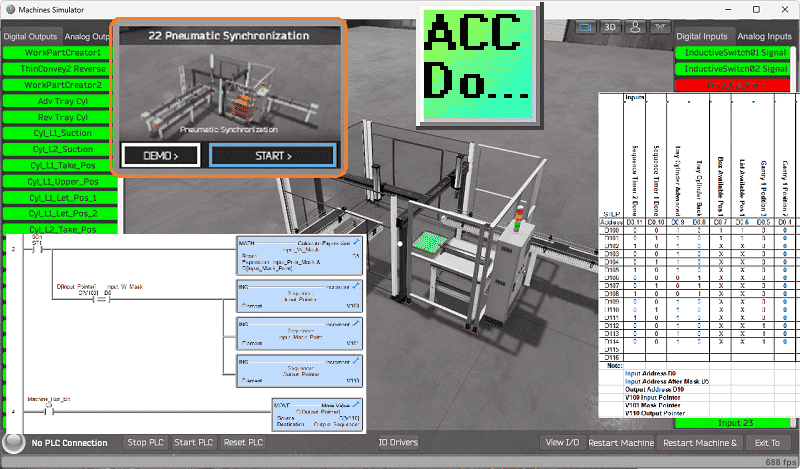

– PLC Programming Example – Pneumatic Synchronization – Video

This article covers the programming of pneumatic cylinders in sequence, including defining the task, inputs and outputs, and the actual programming logic.

Pneumatic synchronization with advanced programmable logic controller (PLC) programming solutions offers a reliable and efficient way for discrete parts manufacturers to control their production lines. By connecting compressed air cylinders to the PLC through a timing mechanism, the system can be easily programmed to repeat machine motions or cyclic actions accurately and consistently.

This is especially valuable for manufacturers who require precise gestures and repetitive movements during part fabrication. With all these benefits combined, PLC pneumatic sync programming will significantly reduce production costs while improving overall product quality in automation applications. The five steps for PLC program development were followed and showed you how to utilize this pneumatic synchronization. EasyPLC pneumatic synchronization machine will be connected to the Do-More designer PLC simulator using Modbus TCP (Ethernet). Assembly of boxes will be done from two conveyor input lines. The process will then put the completed box on the output conveyor line.

– PLC Programming for Beginners: 17 Common Questions Answered! – Video

This piece addresses various fundamental aspects of PLC programming, such as what a PLC is, types of PLCs, ladder logic, and basic components of a PLC system. PLC programming for beginners can seem intimidating, but it doesn’t have to be. With the right resources, anyone can get up and running quickly.

Here are the 17 most frequently asked questions. This is a great place to start for anyone learning about PLC programming. Through thorough explanations of key concepts and answers to many of the most common questions about PLC programming, this ACC Automation resource should give you all the information you need to take your first steps into PLC programming. We discussed the common questions for PLC programming using several different manufacturers of PLC hardware and software. Ultimately, you will see my recommendation for a beginner in learning industrial automation.

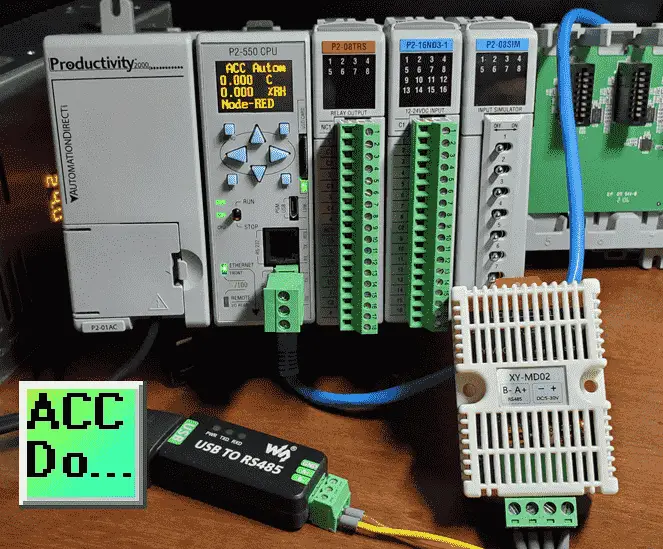

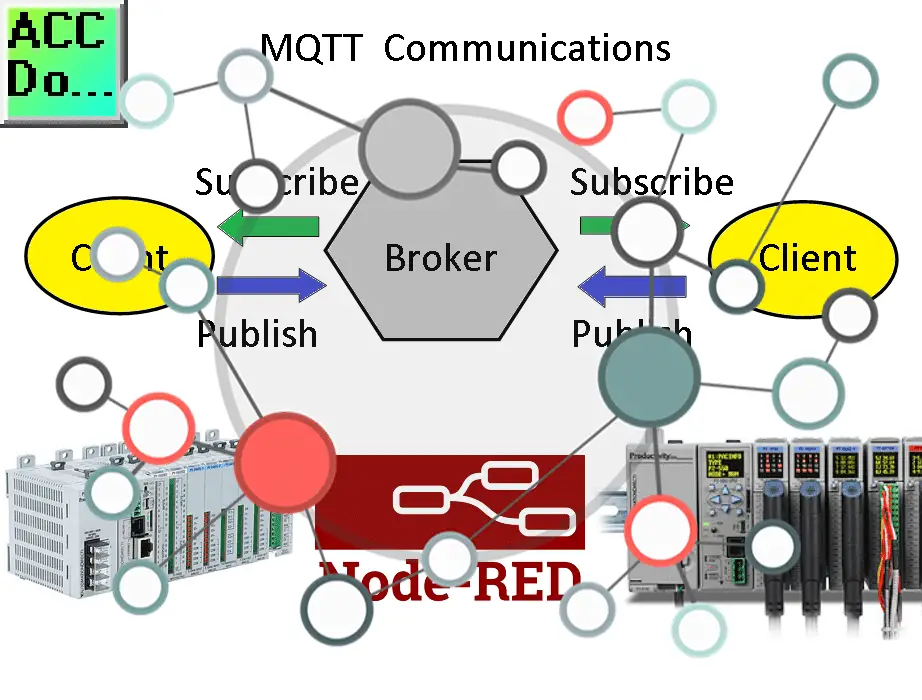

– Various topics related to PLC programming, IoT Industry 4.0, including communication between the Productivity 2000 PLC and Node-RED – Video

We examined communication between the Productivity 2000 PLC (Modbus TCP Server) and Node-RED (Modbus TCP Client). Node-RED is a powerful, adaptable HMI/SCADA (Supervisory Control and Data Acquisition) development package that uses flow programming. Minimal coding is required; you can see the program flow visually. The best thing is that the software is free. We looked at using Node-RED with the Productivity 2000 Series PLC. Node-RED was used to create a single Modbus flow. We communicated to our XY-MD02 Temperature and Humidity sensor using Modbus RTU on a serial RS485 network. The present values of the sensor will be read. These values were written to our Productivity 2000 PLC using an Ethernet Modbus TCP network. These temperature and humidity readings were then displayed on the P2000 CPU.

Present… ACC Automation 2023

These topics provide a good overview of the areas covered by ACC Automation in the past year, focusing on PLC programming, beginner’s guides, and related industrial automation concepts. We are currently covering the Arduino OPTA IoT PLC. Arduino, the leading open-source electronics platform, has launched a new piece of hardware called the Arduino Opta IoT PLC. The device has been designed to enable the development of advanced industrial automation solutions, making it a game-changer in the world of IoT and Industry 4.0. We are currently going through the different programming languages used on this controller.

IoT Industry 4.0 (Video) is a hot topic in industrial automation. Industry 4.0 builds on the digital revolution brought by Industry 3.0, which introduced computers like PLCs to the manufacturing floor and took us to the next level of technological advancement. The Internet of Things (IoT) protocol and unified namespace are essential components of Industry 4.0. IoT enables physical devices and systems to collect and exchange data, while a unified namespace ensures seamless communication and information sharing within manufacturing environments. Industry 4.0 can be complex to understand, but it also presents new business opportunities.

By embracing digital transformation and adopting IoT protocols, companies can leverage data to drive innovation and gain a competitive edge in the market. ACC Automation is here to help!

Future… ACC Automation 2024!

2024 for ACC Automation will prove to be an exciting time. We will continue with our current series with additional examples of this 3D simulation of the process. This will be done with the physical PLC hardware and the machine simulator from EasyPLC.

Further Node-Red IoT flow programming and implementation examples will be demonstrated. This will include further discussion on the “Unified Name Space,” “IoT protocol,” etc.

As always, we will answer your questions and applications so you can quickly implement your control solution.

Accelerate Learning …

Accelerate Machines…

Accelerate Knowledge…

ACC Automation

Watch on YouTube: ACC Automation 2023 Review – PLC Learning

If you have any questions or need further information, don’t hesitate to contact me.

Thank you once again for supporting the website in 2022!

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.