Pneumatic synchronization with advanced programmable logic controller (PLC) programming solutions offers a reliable and efficient way for discrete parts manufacturers to control their production lines. By connecting compressed air cylinders to the PLC through a timing mechanism, the system can be easily programmed to accurately and consistently repeat machine motions or cyclic actions. This is especially valuable for manufacturers who require precise gestures and repetitive movements during part fabrication. With all these benefits combined, PLC pneumatic sync programming will significantly reduce production costs while improving overall product quality in automation applications.

The five steps for PLC program development will be followed and will show you how to utilize this pneumatic synchronization. EasyPLC pneumatic synchronization machine will be connected to the Do-More designer PLC simulator using Modbus TCP (Ethernet). Assembly of boxes will be done from two conveyor input lines. The process will then put the completed box on the output conveyor line. Let’s get started.

Learn PLC programming the easy way. See below for a 10% discount on this cost-effective learning tool. Invest in yourself today.

Previously we have done the following:

Easy PLC Installing the Software – Video

EasyPLC Software Suite – Quick Start – Video

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

Do-More PLC – EasyPLC Box Selection Program – Video

Click PLC EasyPLC Gantry Simulator – Video

Click PLC Simple Conveyor EasyPLC – Video

EasyPLC Paint Line Bit Shift – BRX Do-More PLC – Video

Click PLC – EasyPLC PLC Mixer Programming – Video

Click PLC EasyPLC Warehouse Stacker Example – Video

– Operation Video

EasyPLC Machine Simulator Productivity PLC Robotic Cell – Video

EasyPLC Simulator Robotic Cell Click PLC – Video

EasyPLC Simulator Robotic Cell BRX Do-More PLC – Video

– EasyPLC Factory Editor Robotic Cell Additions Video

4 Way Traffic Light PLC Program EasyPLC – Video

Rock Crusher Plant EasyPLC BRX Do-More – Video

Freight Carrier Weighing and Distribution EasyPLC – Video

EasyPLC Machining Center Loading Robots – Video

EasyPLC Palletizing Robot Programming Click PLC – Video

EasyPLC Machine Editor – Design a Simulation – Video

PLC Programming Mixing Tank – EasyPLC / Do-More – Video

EasyPLC Solder Robot PLC Programming – Video

PLC Programming – A Tutorial for Beginners – Video

Automated Parking Demo Video

Parking Cars Simulator PLC Programming Part 1 – Video

Parking Cars Simulator PLC Programming Part 2 – Video

Define the task: (Step 1 – EasyPLC Pneumatic Synchronization)

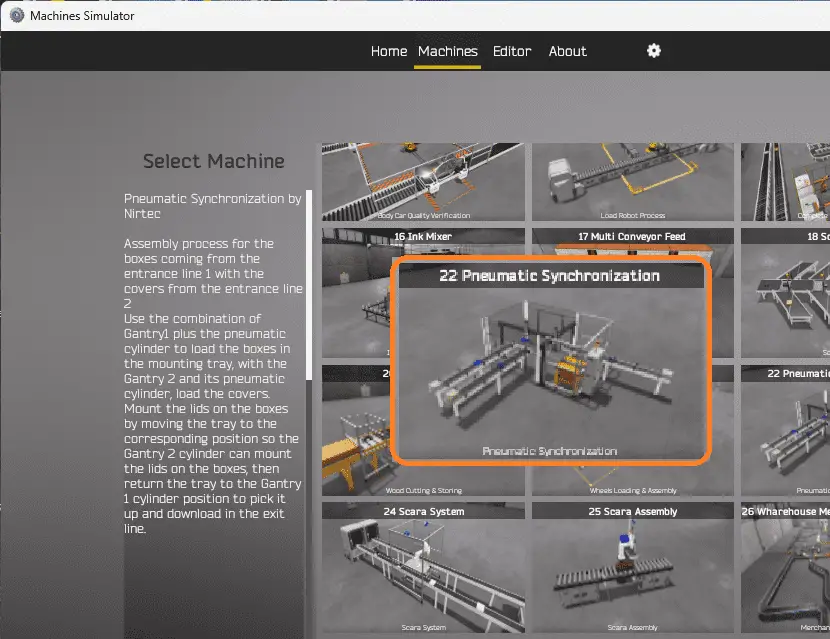

The first step of PLC program development is to define the task to determine what must be done. EasyPLC software suite contains this pneumatic synchronization example in the machine simulator. This is just one of many machines that come with the software so you can learn and develop your PLC programming skills.

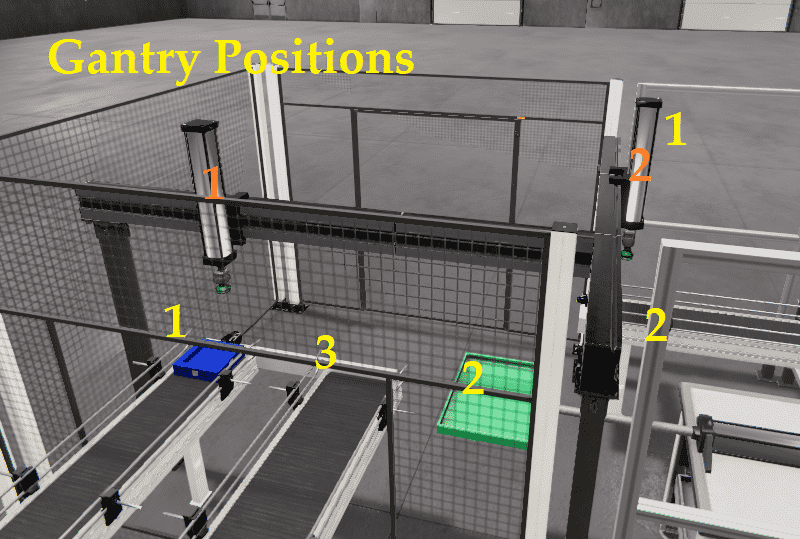

The objective of the assembly process is to make boxes. Boxes come from entrance line 1, and the covers from entrance line 2. Load the boxes on the mounting tray using the combination of gantry one plus the pneumatic cylinder. Gantry 2 and its pneumatic cylinder will load the covers. Mount the lids on the boxes by moving the tray to the corresponding position so Gantry 2 cylinder can mount the lids on the boxes. Return the tray using the gantry one cylinder to pick it up and position it on the exit line.

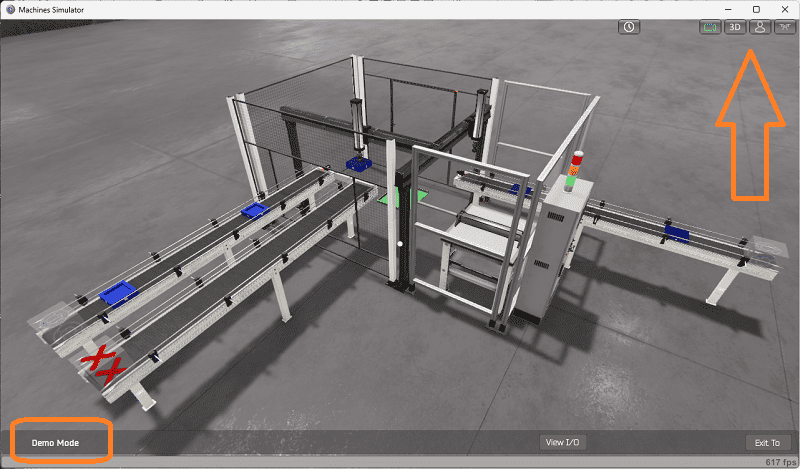

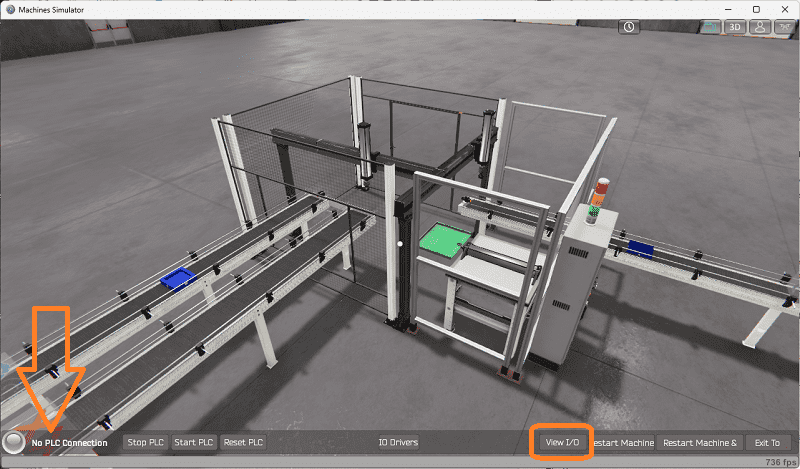

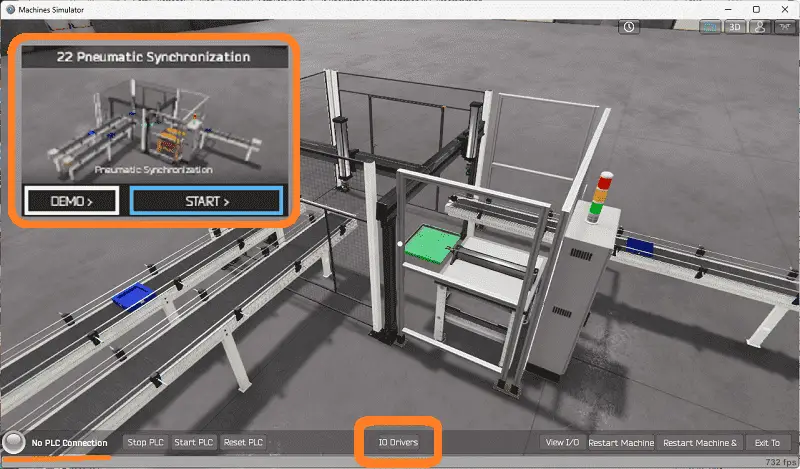

Start the EasyPLC Machine Simulator (MS). Select the start button on the main page or select machines from the main menu on the top of the machines simulator window.

All the available machines will now be displayed. Click on the “Pneumatic Synchronization.”

This is the example that we will be programming. To the left of the screen, information will be displayed on how this process needs to function.

This is printed above.

The machine simulator has a demo mode for the built-in machines. This will allow you to watch the operation of the pneumatic synchronization machine. Select the demo mode.

The EasyPLC demo mode on the machine simulator will operate, showing you the basics of operation.

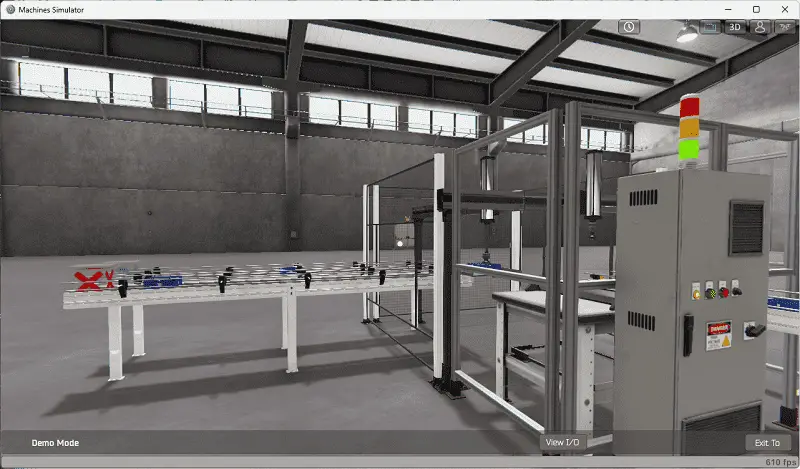

Move around the 3D virtual environment. Three icons on the top of the window will allow you to move around this 3D environment. The first icon is the default selection. This will enable you to move around without bumping into the components.

The first-person mode will mimic a person in your 3D learning world. The last icon will automatically show you around this virtual environment. Once we understand what must be done, we can move on to the next step in our PLC program development.

Define the Inputs and Outputs: (Step 2 – EasyPLC Pneumatic Synchronization)

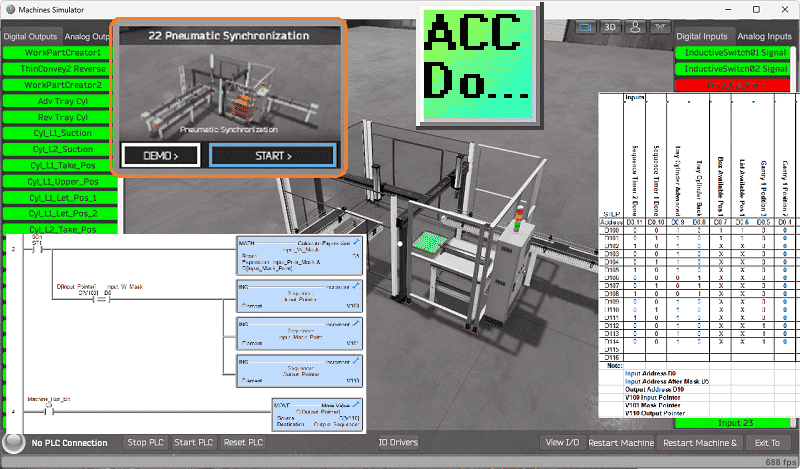

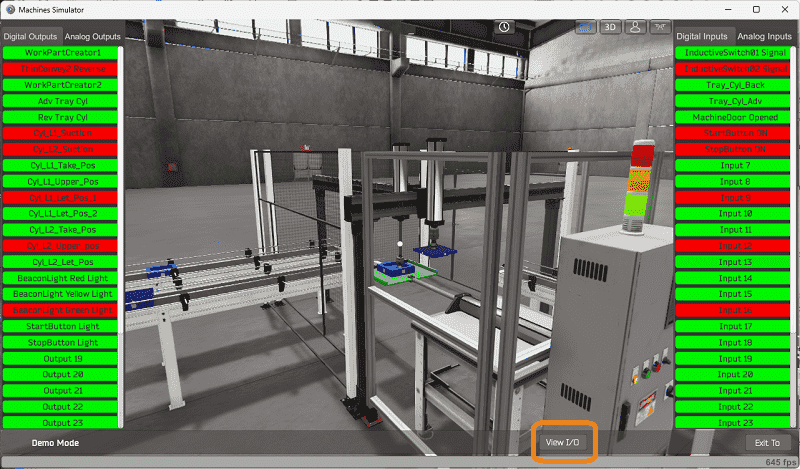

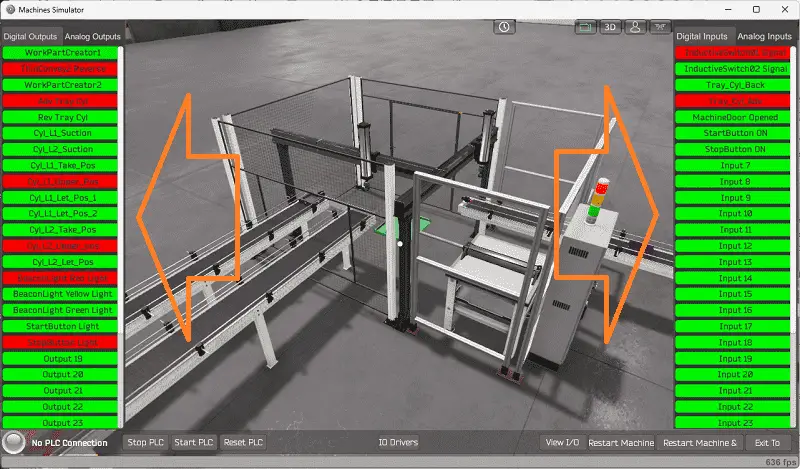

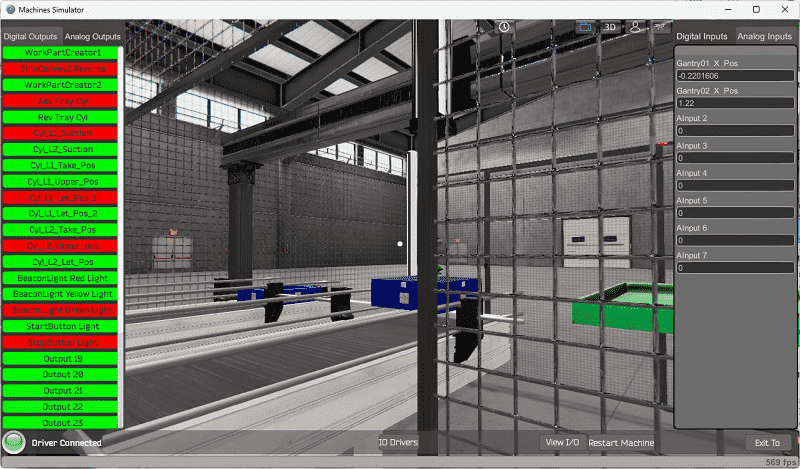

The View IO at the bottom of the machine simulator window will display the inputs and outputs required for this pneumatic synchronization example. While still in demo mode, you can see the operation of the inputs and outputs.

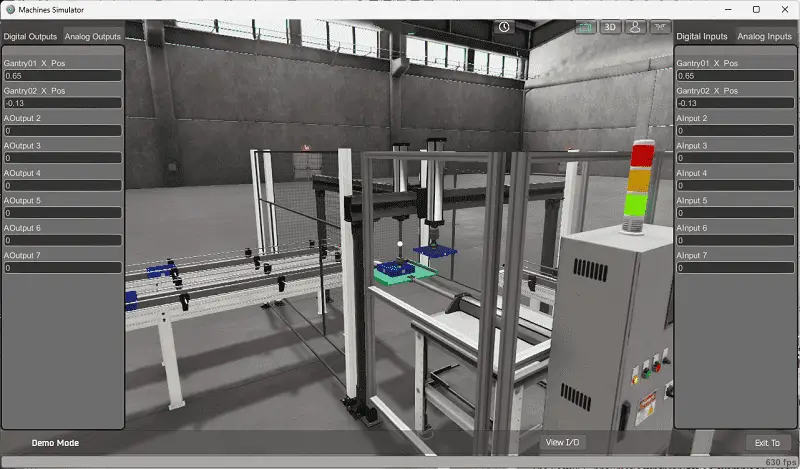

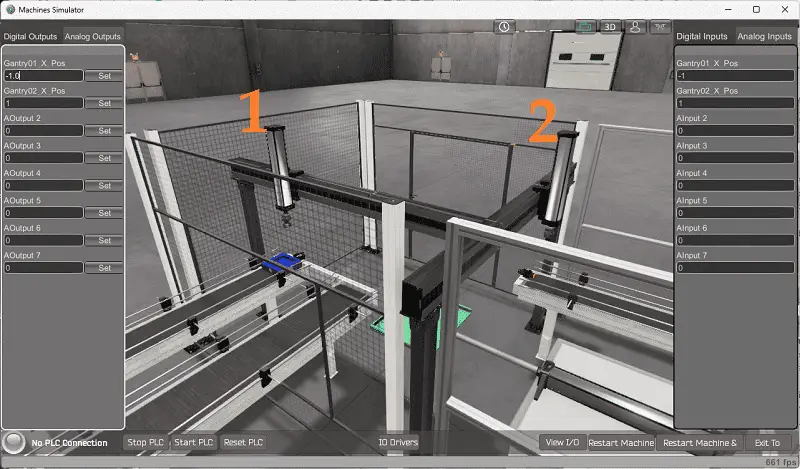

The EasyPLC pneumatic synchronization example will require 19 digital outputs and seven digital inputs. Select the analog outputs and inputs in “demo” mode.

Pneumatic synchronization will also require two analog outputs and two analog inputs. These are used for the movement of the two gantries. One analog output is used for setting the position required, and the input is for feedback on the actual position of the gantry.

Note the three positions required for gantry one and the two as necessary for gantry 2.

The EasyPLC start mode will allow you to control the pneumatic synchronization simulator manually. Exit the demo mode and enter the start mode for this machine.

This is ideal if you need clarification on what an output or input is doing.

Select the View IO on the bottom middle of the machine simulator window. You can manually run the machine simulator without any control or PLC connection.

You can now select the pneumatic synchronization digital outputs on the left side of the screen by clicking on them with the mouse. The right side will show you the corresponding digital inputs. Select the analog outputs and inputs. Entering the positions for each gantry will show you how the analog output and feedback work.

The restart button on the bottom of the machine simulator window will reset the scene back to the start.

Before programming, you must know the function and operation of each input and output.

The following table will define the inputs and outputs (IO) and Modbus addresses in the Do-More Designer Simulator PLC we will use for this program.

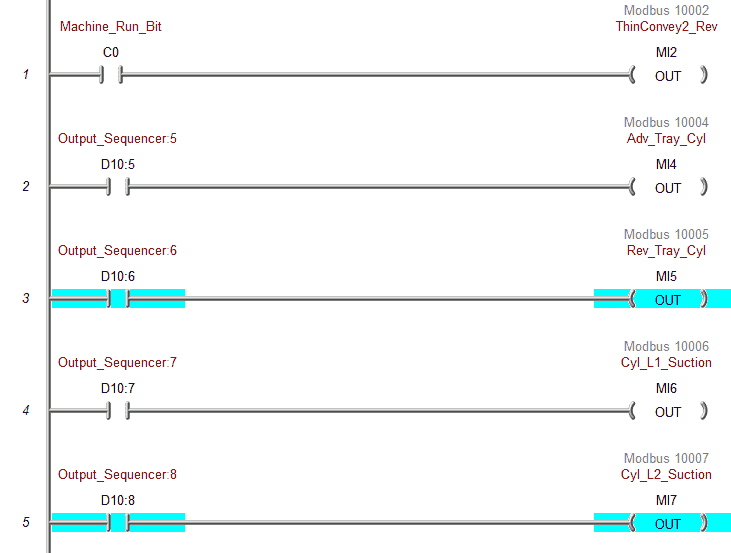

| Digital Type | Description | Do-More PLC Modbus Address | Machine Simulator Modbus Address |

| PLC Output – MS Input | Work Part Creator 1 | MI1 – 10001 | 0 |

| PLC Output – MS Input | Thin Conveyor 2 Reverse (Exit) | MI2 – 10002 | 1 |

| PLC Output – MS Input | Work Part Creator 2 | MI3 – 10003 | 2 |

| PLC Output – MS Input | Advance Tray Cylinder | MI4 – 10004 | 3 |

| PLC Output – MS Input | Reverse Tray Cylinder | MI5 – 10005 | 4 |

| PLC Output – MS Input | Cylinder L1 Suction | MI6 – 10006 | 5 |

| PLC Output – MS Input | Cylinder L2 Suction | MI7 – 10007 | 6 |

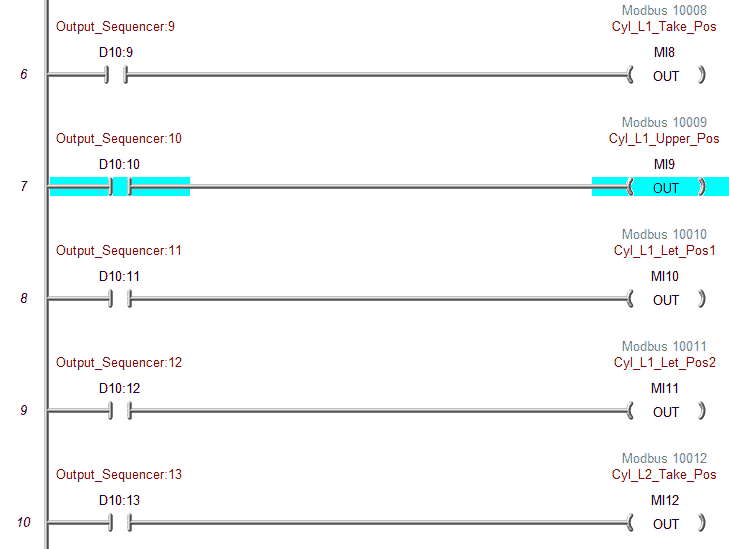

| PLC Output – MS Input | Cylinder L1 Take Position | MI8 – 10008 | 7 |

| PLC Output – MS Input | Cylinder L1 Upper Position | MI9 – 10009 | 8 |

| PLC Output – MS Input | Cylinder L1 Let Position 1 | MI10- 10010 | 9 |

| PLC Output – MS Input | Cylinder L1 Let Position 2 | MI11 – 10011 | 10 |

| PLC Output – MS Input | Cylinder L2 Take Position | MI12 – 10012 | 11 |

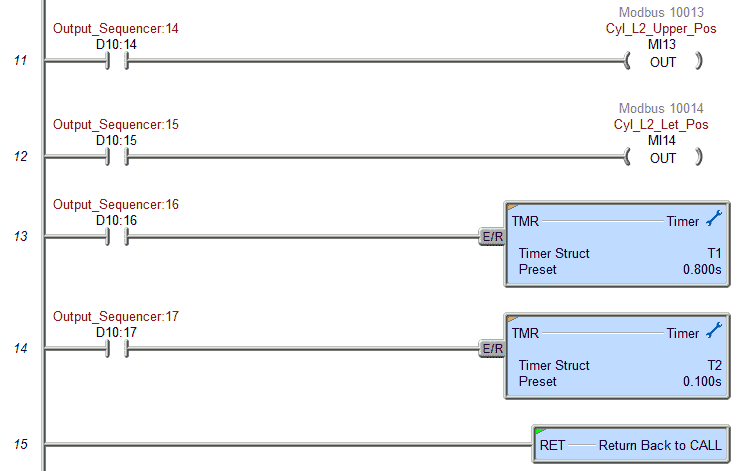

| PLC Output – MS Input | Cylinder L2 Upper Position | MI13 – 10013 | 12 |

| PLC Output – MS Input | Cylinder L2 Let Position | MI14 – 10014 | 13 |

| PLC Output – MS Input | Beacon Red Light | MI15 – 10015 | 14 |

| PLC Output – MS Input | Beacon Yellow Light | MI16- 10016 | 15 |

| PLC Output – MS Input | Beacon Green Light | MI17 – 10017 | 16 |

| PLC Output – MS Input | Start Button Light | MI18 – 10018 | 17 |

| PLC Output – MS Input | Stop Button Light | MI19- 10019 | 18 |

| PLC Input – MS Output | Inductive Switch 1 Signal | MC1 – 1 | 0 |

| PLC Input – MS Output | Inductive Switch 2 Signal | MC2 – 2 | 1 |

| PLC Input – MS Output | Tray Cylinder Back | MC3 – 3 | 2 |

| PLC Input – MS Output | Tray Cylinder Advanced | MC4 – 4 | 3 |

| PLC Input – MS Output | Machine Door Opened | MC5 – 5 | 4 |

| PLC Input – MS Output | Start Button ON | MC6 – 6 | 5 |

| PLC Input – MS Output | Stop Button OFF | MC7 – 7 | 6 |

| PLC Analog Output – MS Analog Input | Gantry 1 X Position Set | MHR1 – 1 | 0 |

| PLC Analog Output – MS Analog Input | Gantry 2 X Position Set | MHR2 – 2 | 1 |

| PLC Analog Input – MS Analog Output | Gantry 1 Position | MHR11 – 11 | 10 |

| PLC Analog Input – MS Analog Output | Gantry 2 Position | MHR12 – 12 | 11 |

Note: The machine simulator will be offset by one of the Modbus Addresses. See the video below for the demo mode and determining inputs and outputs.

Develop a logical sequence of operation: (Step 3 – EasyPLC Pneumatic Synchronization)

A PLC programmer must know everything about the sequence and operation of the machine before programming. The pneumatic synchronization simulator is an excellent way to learn to program. Flow charts or sequence tables can be used to understand the process that needs to be controlled thoroughly. It must also answer questions like the following:

What happens when electrical power or pneumatic air is lost? What happens when the input/output devices fail? Do we need redundancy?

This step is where you will spend most of your time. Understanding everything about the operation will save you time. It will help prevent you from continuously re-writing the PLC program logic. Knowing all these answers to how the system is to react is vital in developing the PLC program. This does not have to be a formal document. You have to have a method to account for every condition in the machine being programmed.

Our machine has a control panel and beacon lights. If the machine is stopped and ready to be started, the start pushbutton light will flash. If the machine is running, the red stop light will be on. The beacon lights will display green if the machine is running and red when it is stopped. If the door is opened, the yellow light will be on.

The machine is reset by pressing the stop button twice within 0.8 seconds.

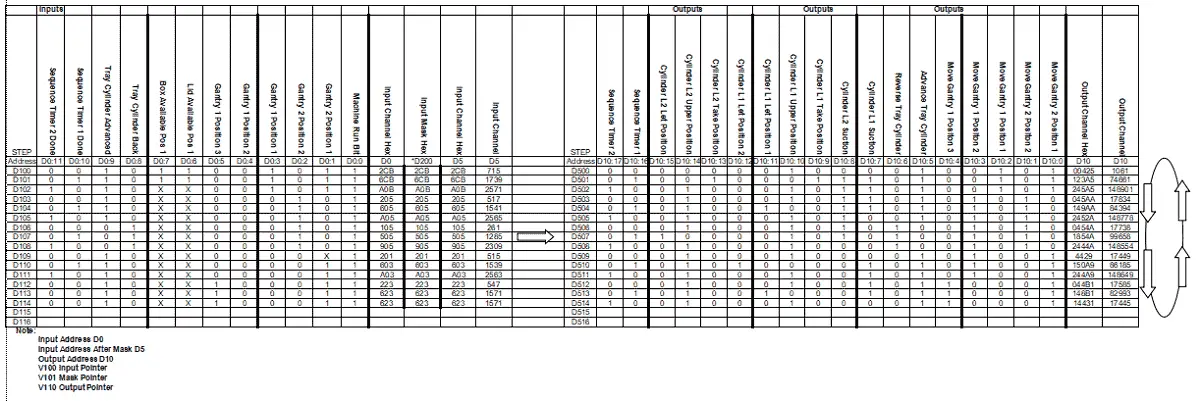

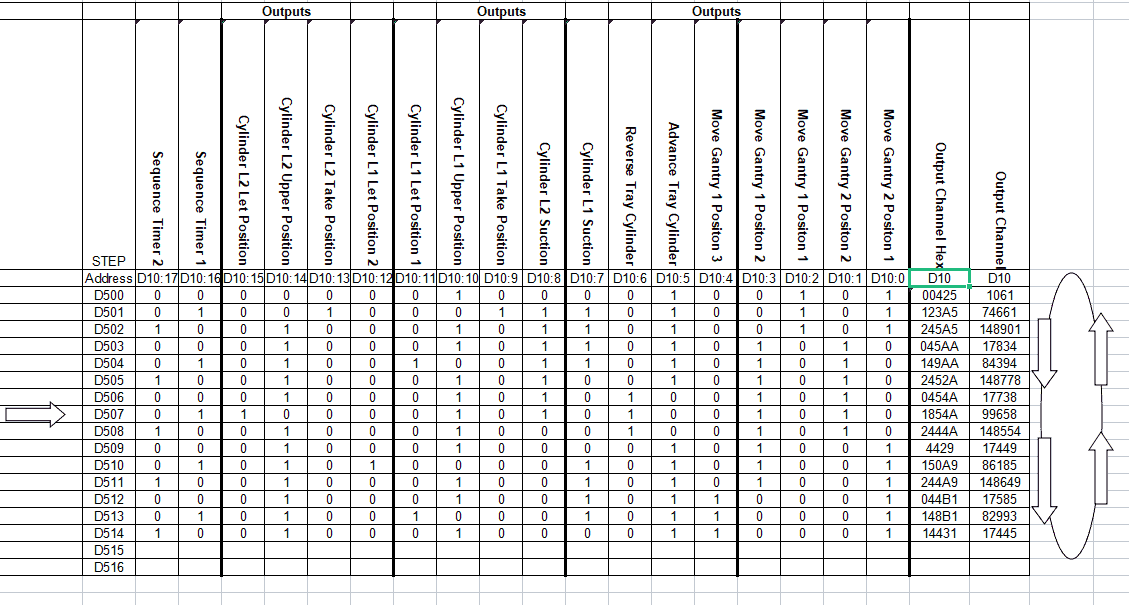

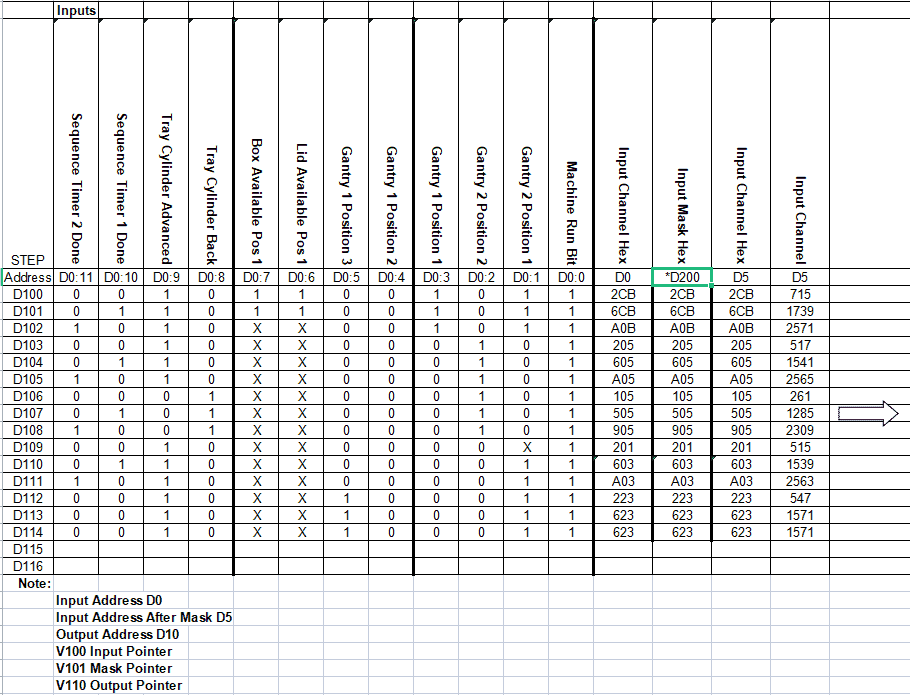

Our EasyPLC pneumatic synchronization operation can easily be viewed using a sequence table.

At first, this may seem confusing; however, the sequence table is read from left to right. If the input conditions are met, the output conditions are set. Let’s look at the output table.

This will show you the output sequence for the machine. The gantry positions are a discrete output in the table. We want to coordinate the movements, so we show the possible gantry positions.

Each gantry position output will have a corresponding input position. This will be used to move on to the next step of the sequence.

The pneumatic cylinders do not have sensors when they extend or retract, so timers are used. One timer is used for extending the cylinder, and one is for retracting the cylinder.

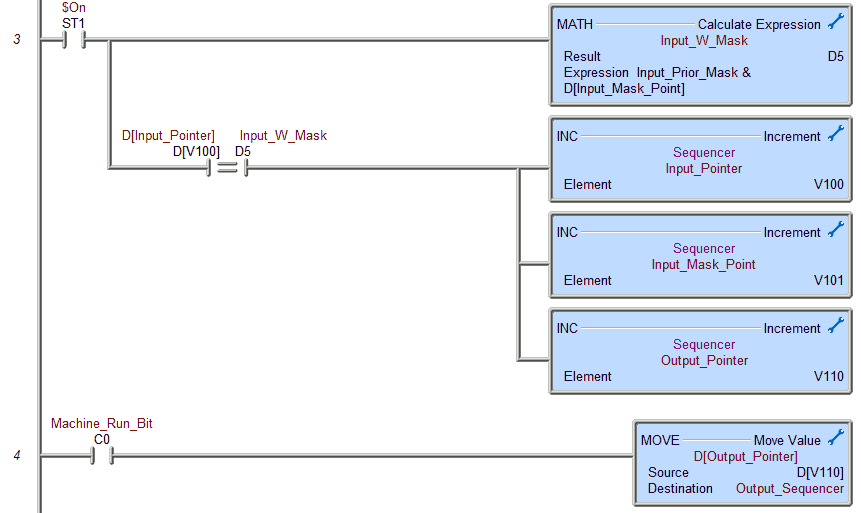

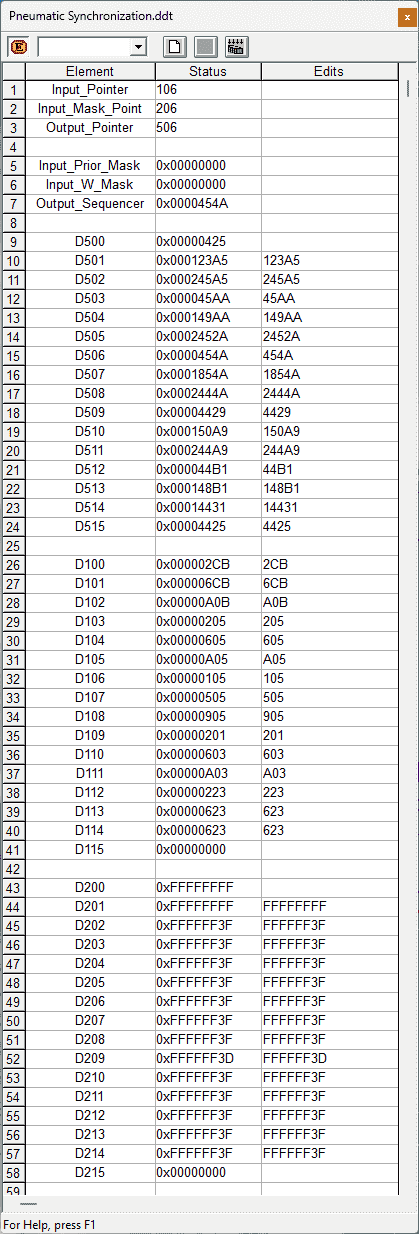

The input sequence table will show all of the possible inputs. A mask allows the sequence to continue if the input is unknown or does not matter. This is accomplished by ANDING the input channel. This will ensure that the input point is always 0 or off. The PLC programming will involve address pointers. This is sometimes referred to as indirect addressing. V100 will be the pointer to addressing the input table starting at D100. V101 is the mask pointer starting at address D200. The output table will begin at D500, and the pointer will be V110.

A PLC programmer must know how everything about the sequence and operation of the machine before programming.

Ensuring you know what has to happen will help clarify what is required in the PLC program. Ask questions or view existing documentation to ensure that you know the logical steps to the machine’s operation. This may involve speaking with the manufacturer, operators, engineers, etc.

Develop the Do-More PLC program: (Step 4 – EasyPLC Pneumatic Synchronization)

Using the information from the previous step, we can now program our Do-More PLC Simulator. The BRX Do-More PLC Series will take you through installing the program, communicating with the controller, providing instructions, and addressing the controller.

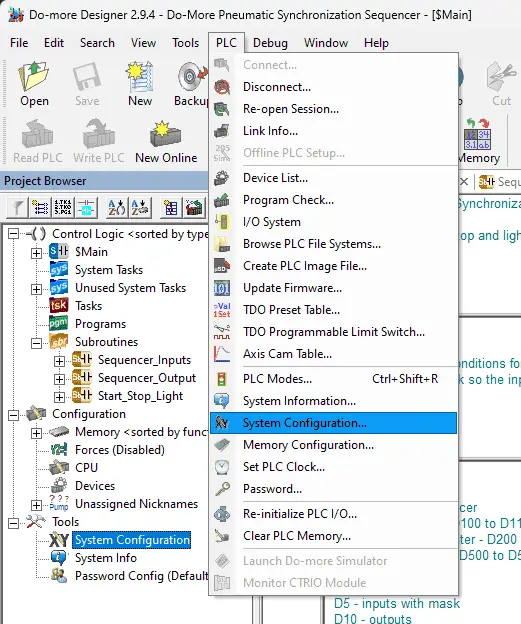

Select the system configuration under PLC on the main menu. You can also call this up by selecting system configuration under the tools menu in the project browser window.

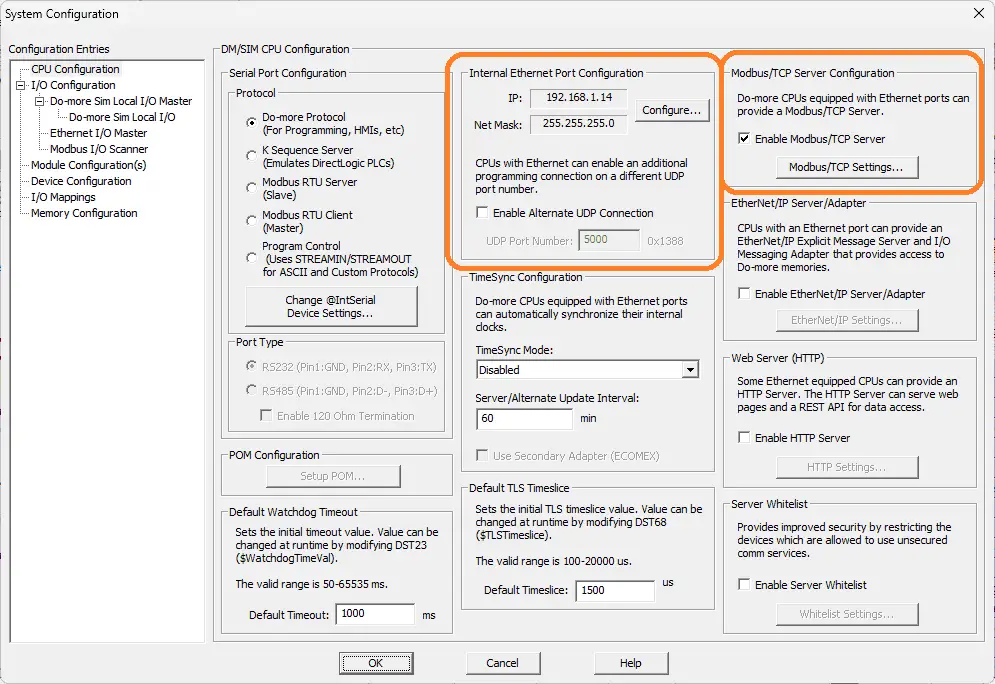

The computer’s IP address can be seen under the “Internal Ethernet Port Configuration.”

Modbus TCP Server is selected by default; however, we can also ensure this is the case in the system configuration window.

Our PLC is now a Modbus TCP Server to the EasyPLC Modbus TCP Client. Please make a note of the static IP address that we are using for the BRX Do-More PLC. This will be used later to connect to the EasyPLC machine simulator.

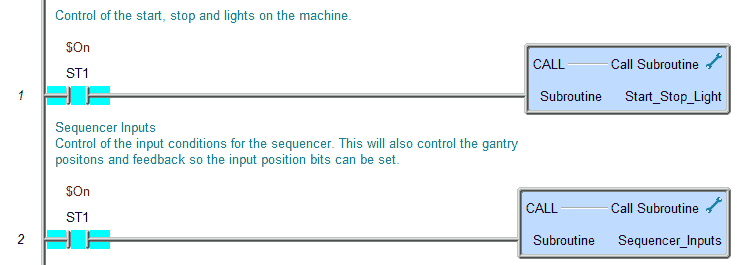

The ladder logic plc programming is split up so that it is easier to read and program. We have subroutines for the sequencer inputs, outputs, and start/stop lights. The main program will control calling these subroutines and the sequencer using indirect addressing.

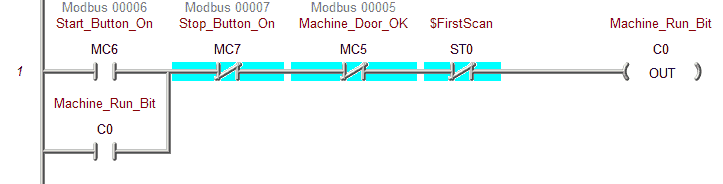

Start_Stop_Light Subroutine

This rung will control the machine run bit.

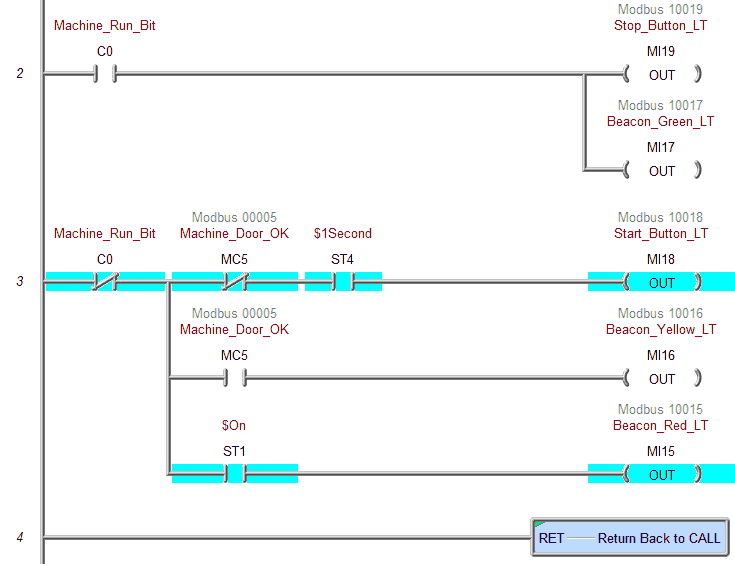

The beacon and pushbutton lights are controlled based on the machine run bit.

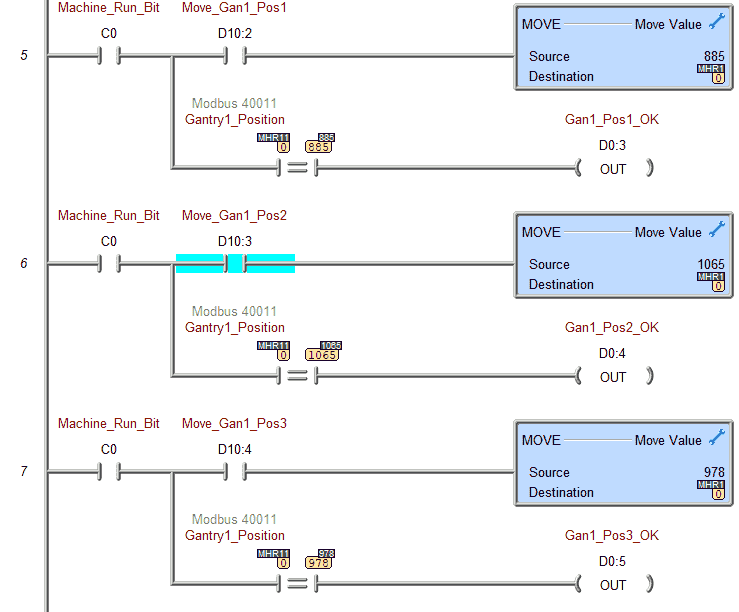

Sequencer_Inputs Subroutine

This section of PLC programming will set the individual bits in word D0 for our sequencer input.

Gantry 2 positions 1 and 2 are being controlled. If the gantry position is requested, the output for the gantry is set. Once the analog input feedback is the same, the positional input bit is turned on. If the machine stops, the set position comes from the feedback position. This will prevent the gantry movement.

Here are the Gantry 1 positions 1, 2, and 3.

This will stop the gantry one movement when the machine run bit is not on. The work part of creating the lids and boxes is on all of the time unless the corresponding input from the inductive switches is activated. This would mean that a part is present.

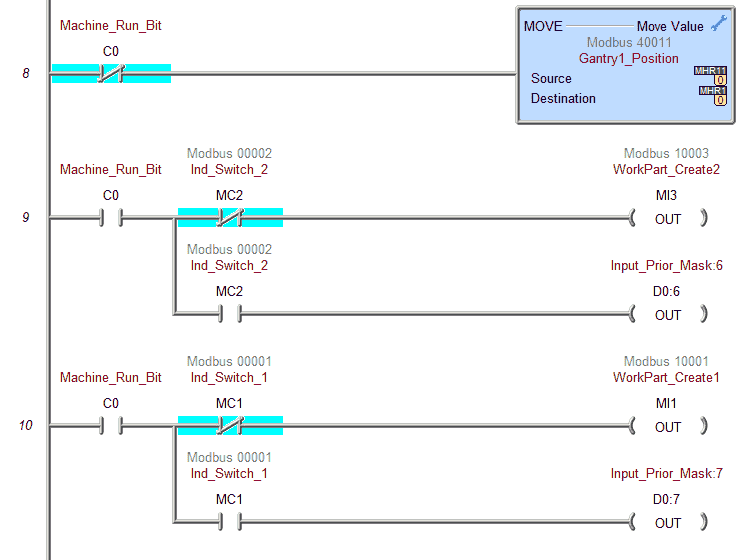

The last of our inputs will be from the tray cylinder and timers.

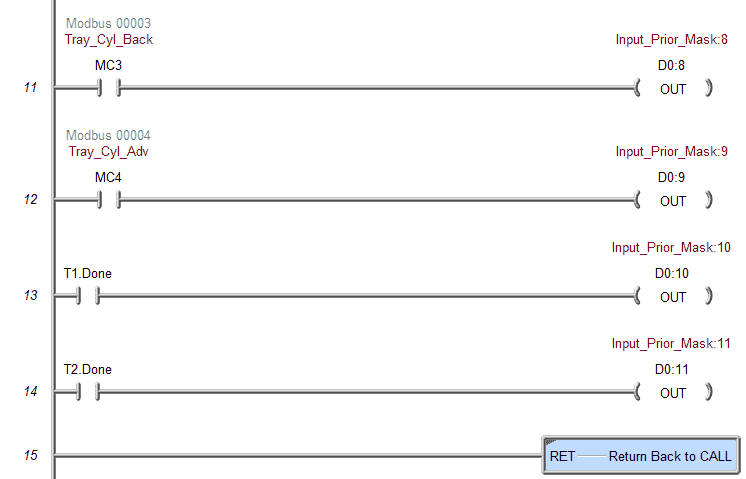

Sequence_Outputs Subroutine

This section of PLC programming will control the outputs from the sequencer output word D10.

Our exit conveyor will be on as long as the machine run bit is on.

Main Ladder Logic

The start-stop and light subroutine are called first. Once this is complete, the sequencer input subroutine is called.

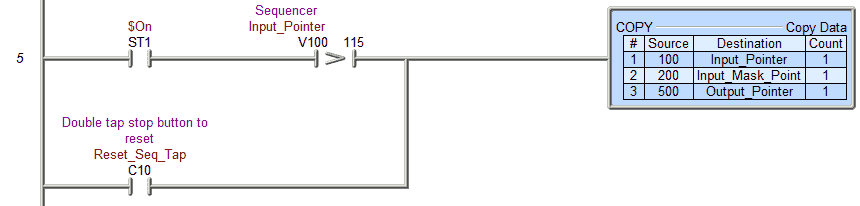

Here is the actual sequencer. The inputs (D0) are masked (ANDED) by D[V101], and the output is sent to D5. The input table D[V100] is compared to D5; if they are equal, the pointers are incremented by 1.

If the sequencer pointer is greater than the end of the table, the pointers are reset. The pointers can also be reset by double-tapping the stop button.

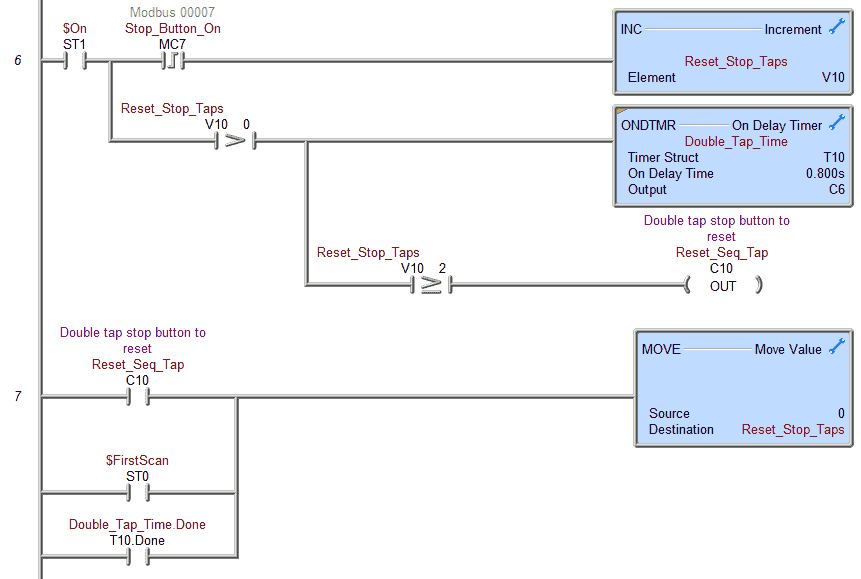

Reset the sequencer pointers if V10 is greater than or equal to 2. The leading edge of the stop button increments a count in V10. If V10 is greater than 0, a timer is started for 0.8 seconds. The next rung will reset the number in V10 if the timer times out, a reset is activated, or the first scan bit of the PLC comes on.

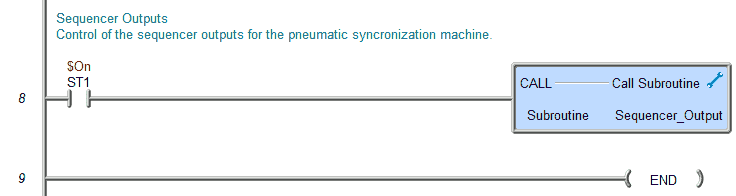

The last subroutine is called the sequencer output. This will then set our actual outputs.

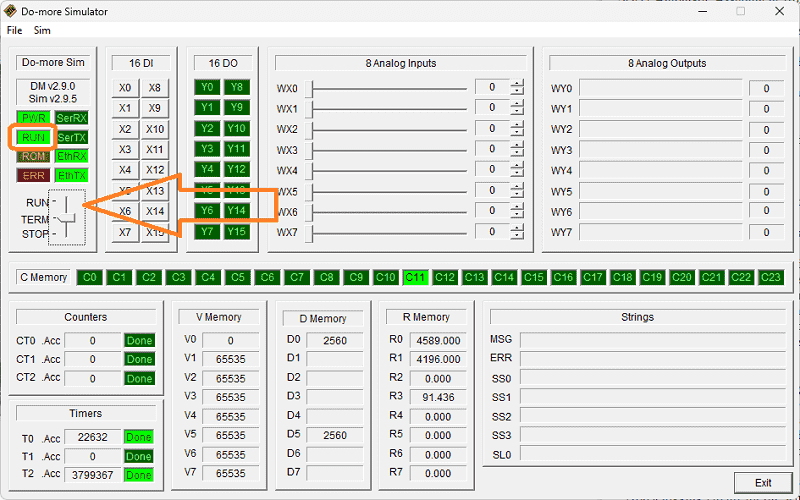

Our ladder logic program is complete. Download the program to the BRX D0-More PLC. Ensure that the controller is in run mode.

We can set the input, output, and mask tables using the Data View.

Watch the video below to see this BRX Do-More PLC program in action.

Test the program: (Step 5 – EasyPLC Pneumatic Synchronization)

We will use Modbus TCP on our Do-More PLC simulator to communicate with the EasyPLC Machine Simulator.

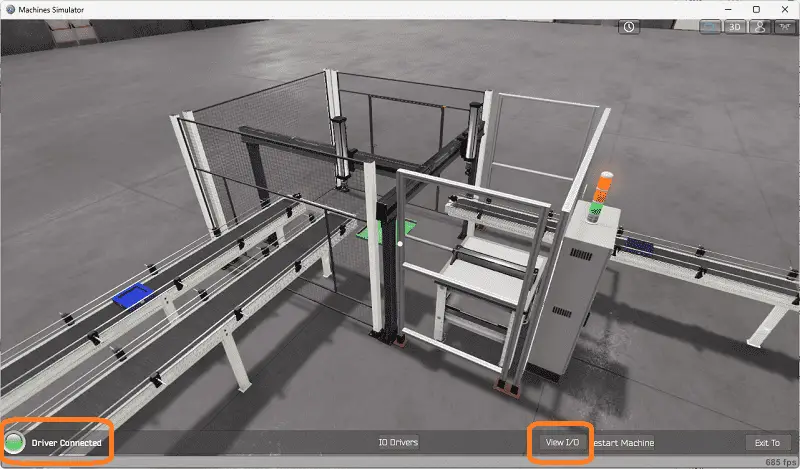

Call up the pneumatic synchronization machine in start mode.

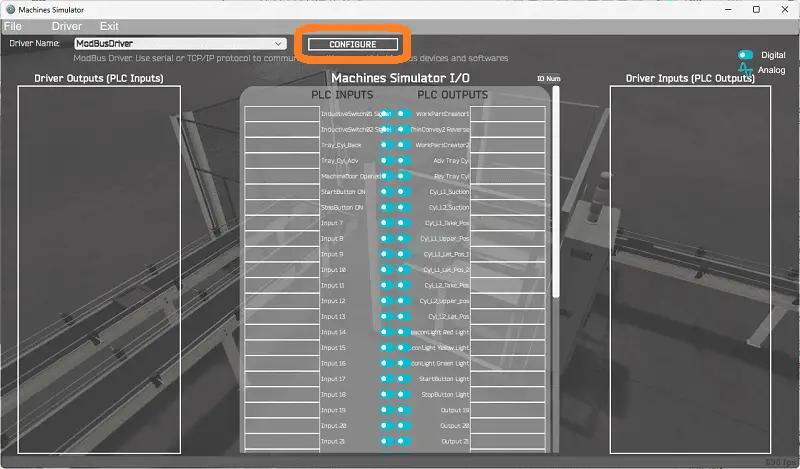

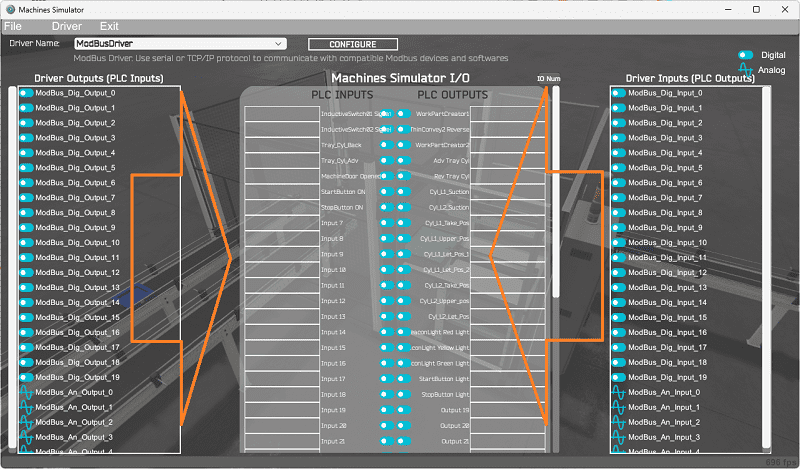

The status of the machine simulator will be at the bottom of the screen. Currently, we have no PLC connected. Select IO Drivers on the bottom middle of the screen.

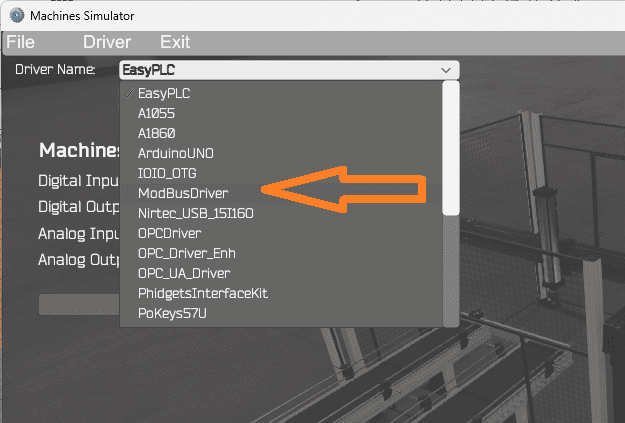

The EasyPLC driver is selected by default. Under the driver pull-down menu, select “ModBusDriver.” This driver will communicate Modbus TCP (Ethernet) and Modbus RTU (Serial). Select the down arrow on the driver’s name.

Select the configure button.

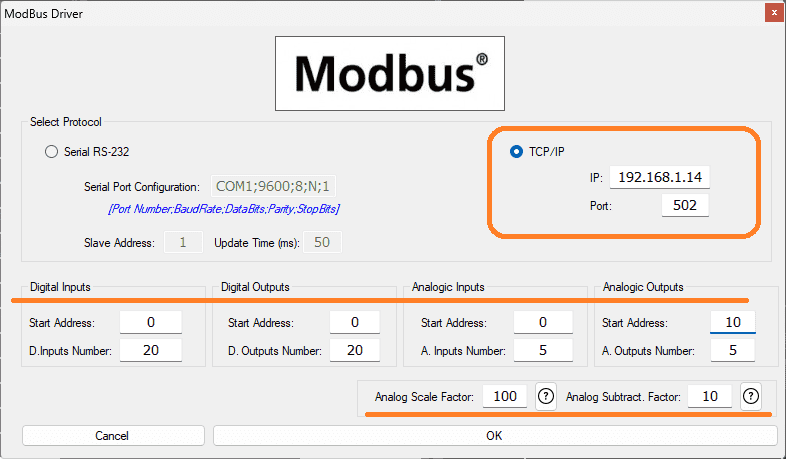

We can now enter the information for our Modbus driver. Select TCP/IP. This means the Ethernet port on the computer will communicate with the PLC.

The digital inputs from MS to the Do-More PLC will be MC1 to MC19. This will start at address 0 due to the offset of 1. Digital outputs from MS to the Do-More PLC will be MI1 to MI7. This will begin at address 0 due to the offset of 1. We are indicating 20 digital inputs and outputs. This is fine because it is more than our EasyPLC machine simulator will require.

Analog inputs from MS to the Do-More PLC will be MHR1 and MHR2. The outputs will be MHR11 and MHR12. Due to the offset of 1, the PLC analog will start at addresses 0 and 10, respectively.

Select the OK button.

You will now see the inputs and outputs specified for the Modbus driver. We can manually assign the driver outputs to the PLC inputs and the driver inputs to the PLC outputs. However, the automatic assignment works well and will save you time.

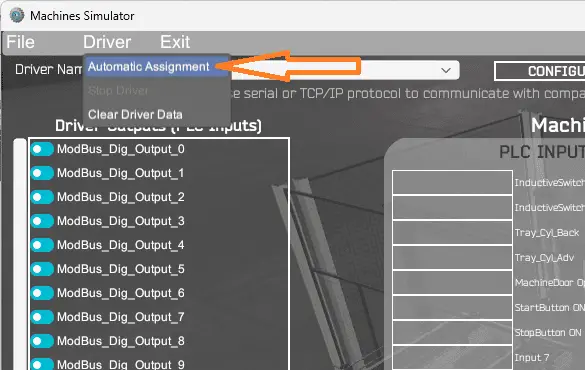

Select Automatic Assignment from the driver option in the main menu.

This will automatically assign the PLC IO to the Machine Simulator IO. Select start driver and exit from the main menu.

On the bottom left side of the window, you will see that the driver communicates to the PLC with the green light. Select view IO to know the input and output status of the machine simulator.

We can also view the analog inputs and outputs.

Ensure that the PLC is in run mode. We can now operate our EasyPLC pneumatic synchronization machine.

Ensure that the PLC is in run mode. We can now operate our EasyPLC pneumatic synchronization machine.

Using the Data View window of the Do-More Designer programming software, we can also watch the inputs and outputs operate.

Watch the video below to see this operation.

If your program works correctly, it’s time to move on. If not, you’ll need to debug. Since we are using indirect addressing, troubleshooting and modifications can easily be accomplished. This can be as simple as re-downloading and re-uploading your program or as complicated as re-designing your logic altogether. Amendments to the sequence table and the corresponding PLC sequence tables will quickly change how your logic works. If the sequencer stops at a location, you can quickly see what inputs should be enabled and what is currently set. This can be displayed on an HMI for troubleshooting.

When using EasyPLC, debugging is quickly done with no damage to any equipment. You may modify your logic several times before you get everything right! That’s okay—it’s all part of learning. After all: trial and error are often easier said than done! To learn more about developing logic, check out our tutorials on the five steps to PLC program development.

You can practice your modification and debug by modifying the pneumatic synchronization in the following way:

– Calculate the cycle time in parts per minute for the machine.

– Add a jogging circuit for the sequencer. This will allow the operator to manually step through the sequence to troubleshoot the logic and machine.

Let me know how you make out in the comments below. These additional exercises will enhance your PLC knowledge and ladder logic programming.

Download the Do-More PLC sample program here.

Watch the video below to see the five steps of program development applied to the pneumatic synchronization machine. The machine simulator is one of the best applications to help you learn PLC programming.

EasyPLC Software Suite is a complete PLC, HMI, and Machine Simulator package. This PLC learning package includes the following:

Easy PLC – PLC Simulation allows programming in Ladder, Grafcet, Logic Blocks, or Script.

HMI System – Easily create a visual human-machine interface (HMI)

Machine Simulator – A virtual 3D world with real-time graphics and physical properties. PLC programs can be tested using EasyPLC or through other interfaces. (Modbus RTU, TCP, etc.)

Machine Simulator Lite – Designed to run on Android Devices.

Machine Simulator VR – Virtual Reality comes to life so you can test, train or practice your PLC programming.

Purchase your copy of this learning package for less than USD 75 for a single computer install or less than USD 100 to allow different computers.

Receive 10% off the price by typing in ACC in the comment section when you order. http://www.nirtec.com/index.php/purchase-price/

Learn PLC programming the easy way. Invest in yourself today.

Watch on YouTube: PLC Programming with Pneumatic Synchronization

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, decimals, Hexadecimal, ASCII, and Floating points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.