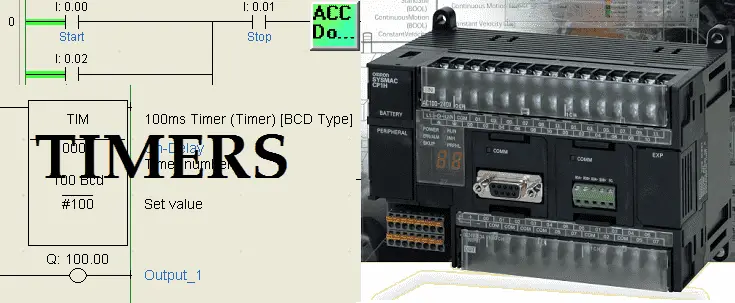

Master Omron CP1H Timer Secrets: 4096 Timers Unleashed!

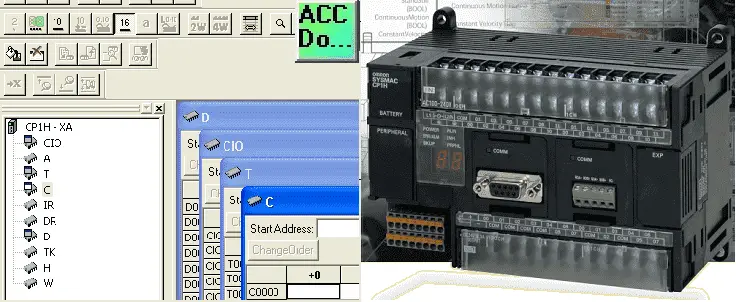

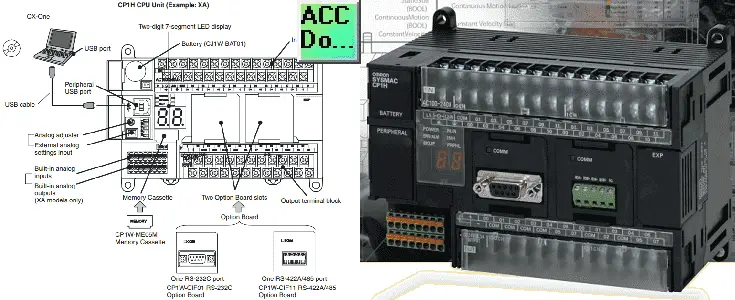

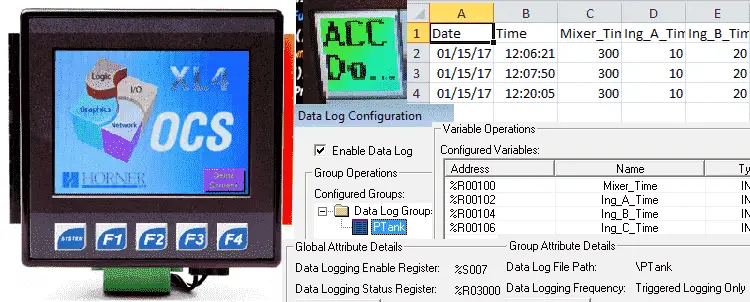

The Omron CP1H series of programmable logic controllers are capable of having 4096 timers. There are twelve different timing instructions in the PLC. Six binary and six BCD instructions for the set values of the timers separate the six basic instructions. The memory area for timers has separate areas for the Timer PVs (Present values) … Read more