The productivity series of PLCs has a built-in web server. This web server function can make a non-secure (HTTP) connection to the CPU. This is done with your browser. You can view read-only system tags and open, save, or delete files stored on the micro SD drive.

Previously we stored data-logged files on the USB (Micro SD) storage device. We will now start and configure the web server function. Look at the files from our data logger and view the system files available. Let’s get started.

Previously in this Productivity 2000 series PLC, we have discussed the following:

P2000 Hardware Features – Video

Productivity Suite Software Install – Video

Communication (System Configuration) – Video

First Program – Video

Debug Mode – Video

PLC Program Documentation – Video

PLC CPU Display – Video

PLC Online Programming – Video

PLC Tag Database – Video

Ladder Logic Contacts – Video

Ladder Logic Outputs – Video

Timers – Video

Counter – Video

Productivity 2000 PLC Ladder Logic Math – Video

Data Handling Instructions

Part 1 – Video

Part 2 – Video

Array Functions

Part 1 – Video

Part 2 – Video

Part 3 – Video

P2000 Program Control – Video

Drum Sequencer Instructions – Video

Data Logger and Logging – Video

Productivity Web Server Configuration

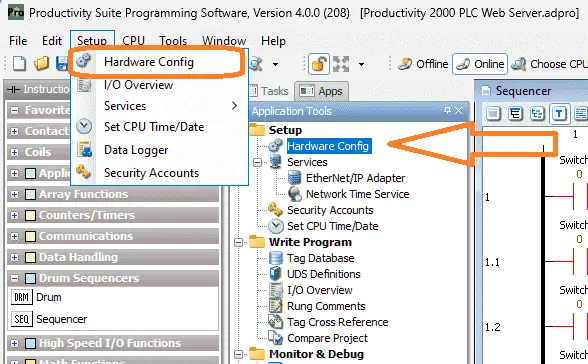

Ensure that you are online with the PLC. Under Setup in the Application Tools menu, select Hardware Config. You can also use the main menu | Setup | Hardware Config…

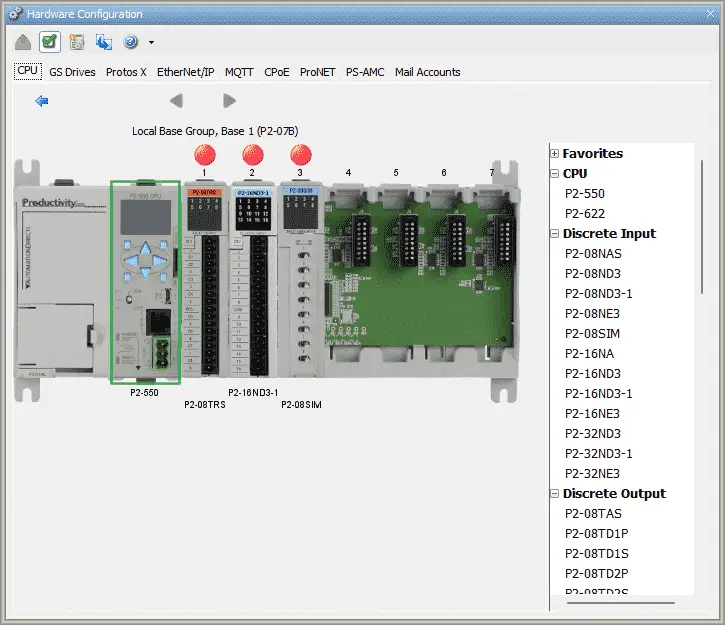

Double-clicking on the CPU module will bring up the CPU Module window.

This has four tabs along the top; Options, Ethernet Port, Remote Access, and Serial Ports. Configuration of the web server is done here.

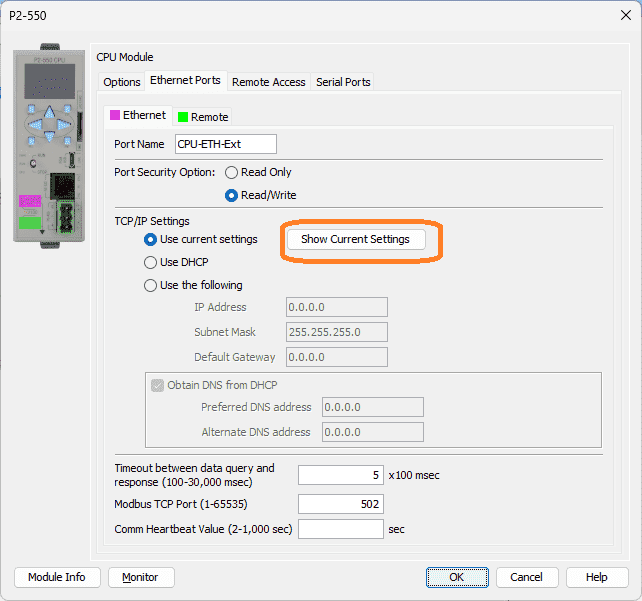

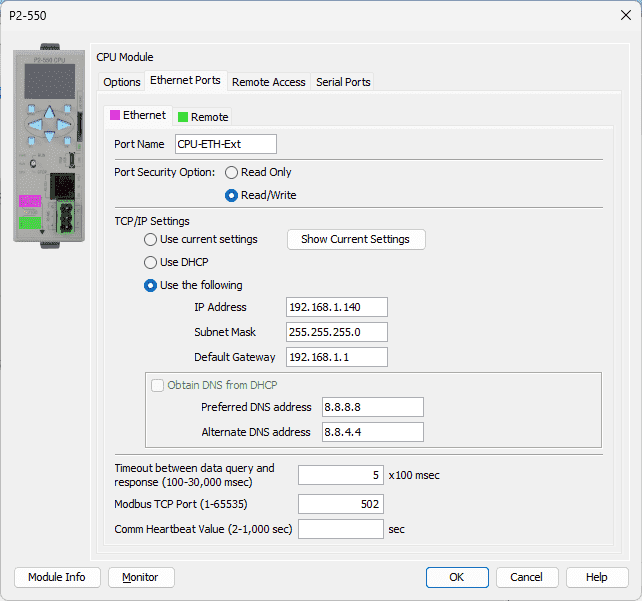

Select the Ethernet Port tab.

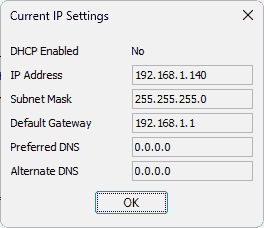

Under the TCP/IP Settings, we want to set our addresses for the PLC. This will ensure that the settings will not be changed when accessing the web server. Select the Show Current Settings button.

Note the settings and select OK.

Select the Use the following radio button and enter the settings noted above.

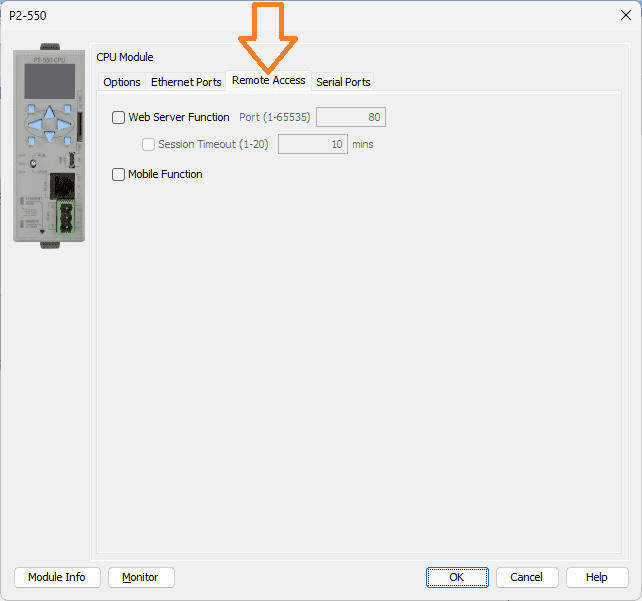

Select the Remote Access tab.

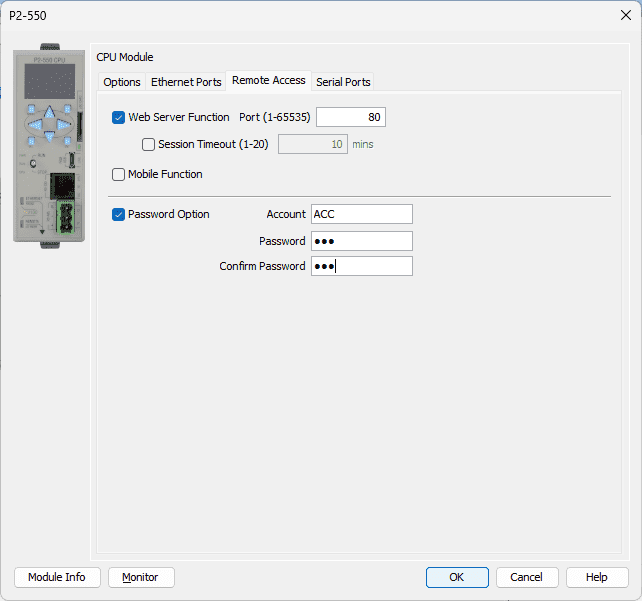

Select the Web Server Function box. We will leave the default port as 80. Port 80 is the port number assigned to the commonly used internet communication protocol, Hypertext Transfer Protocol (HTTP).

Note: I would suggest turning on the Session Timeout if this was on a network. This will automatically log the user out after the set amount of minutes.

Select the Password Option. The account name in our example is ACC, and the password is acc. Select OK once you have entered the information.

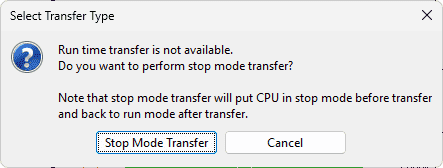

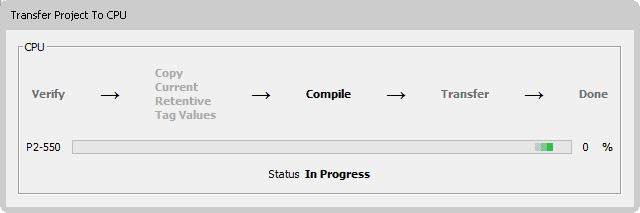

Since we have changed the configuration of the CPU, we perform a program transfer.

This is a stop-mode transfer because of our configuration change.

Once the information is transferred, the PLC can be put into run mode. Our web server should now be available through our browser.

Running the Productivity Web Server

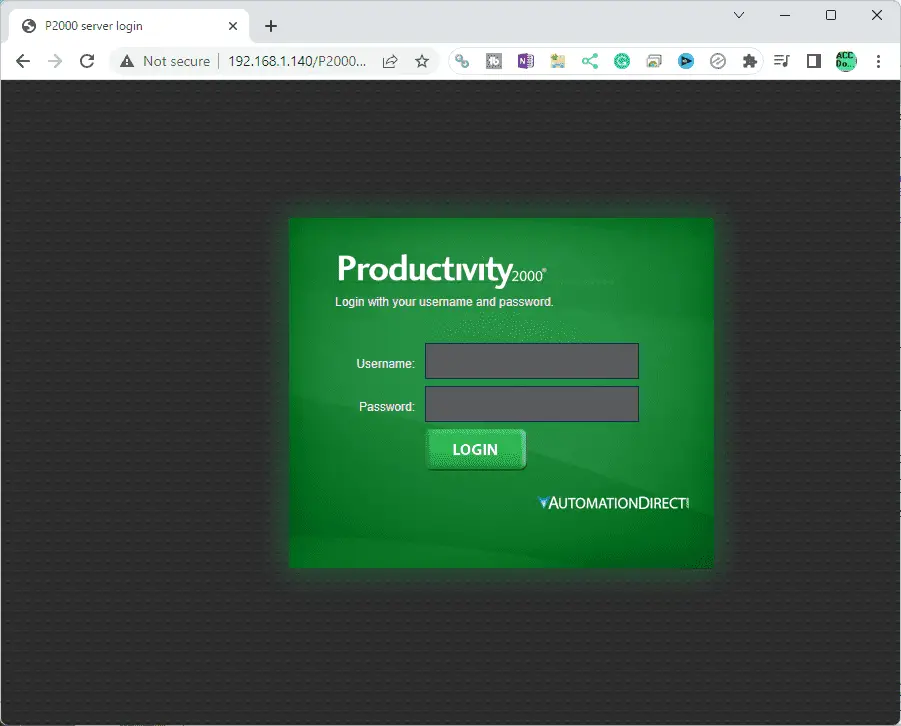

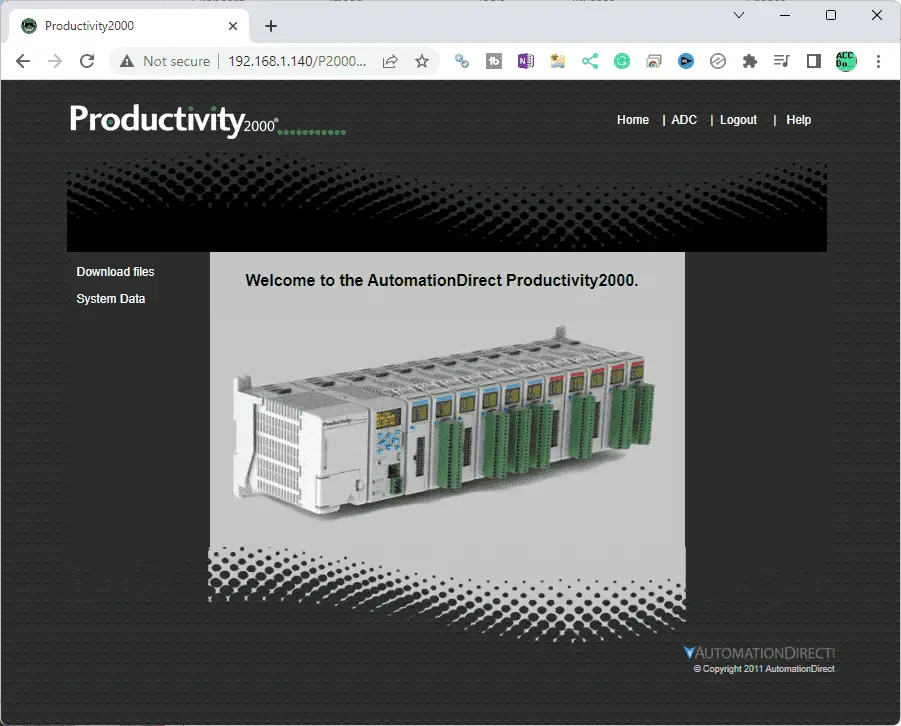

Start your browser. In our case, this is Google Chrome. Enter the IP address of the web server. (192.168.1.140)

This should automatically show you the login screen.

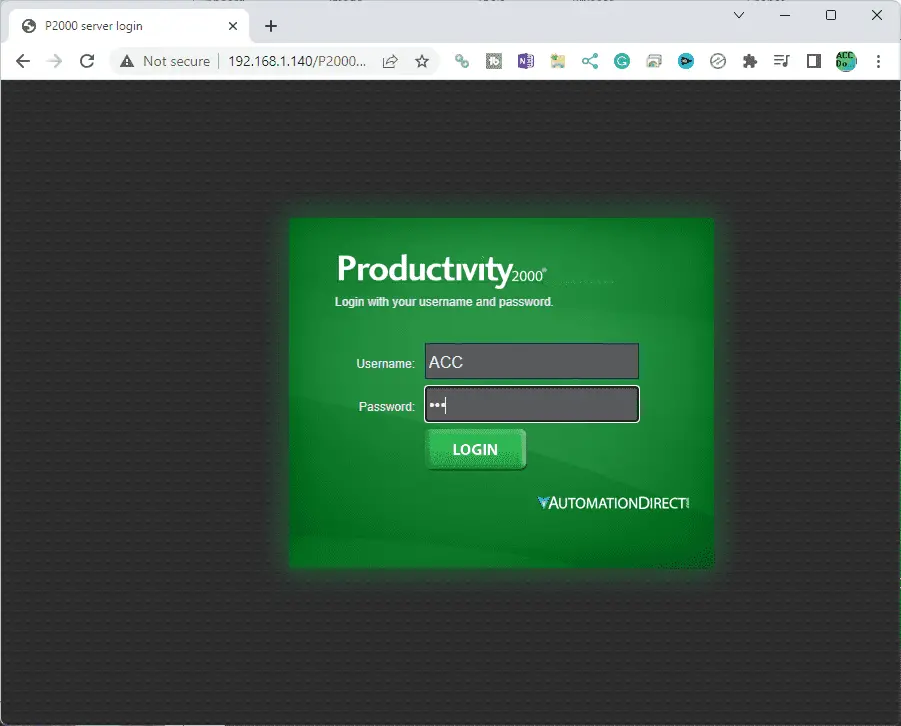

Enter the credentials that we configured for our example. (ACC – acc) Press the LOGIN button.

Home – This is the page that you see above.

ADC – This is a link that will open the Automation Direct website.

Logout – This will log you out of the web server.

Help – This is a link that will open the Productivity 1000 User Manual Online

Download Files – This will allow you to open, save or delete files on the micro SD card.

System Data – This is a read-only of the system data in the PLC.

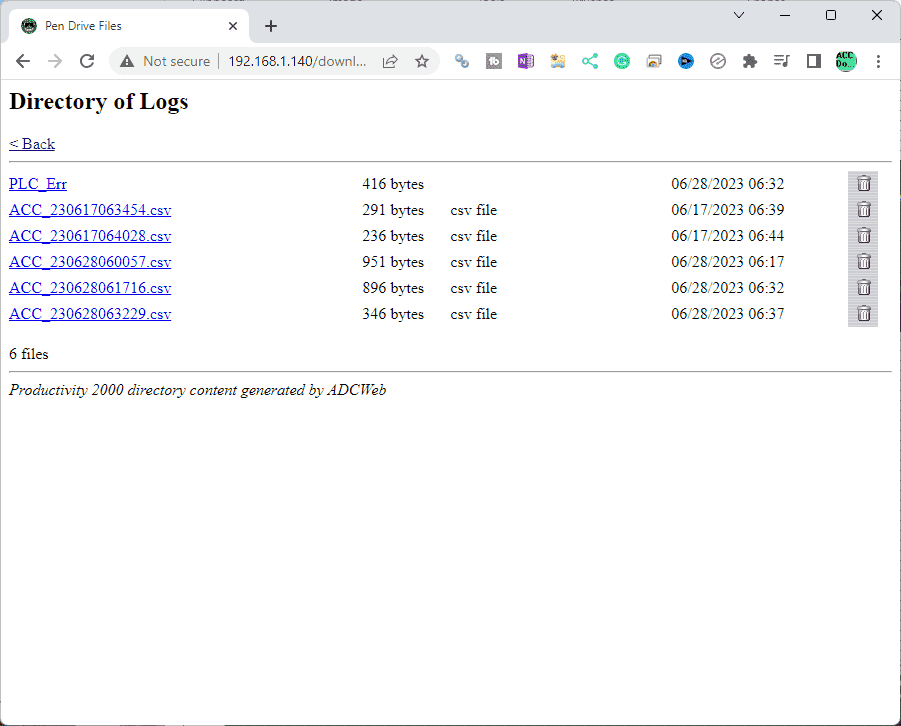

Download Files – Productivity Web Server

Selecting the download files will open the above web page. Here you can click on the file to download it to your computer. Once downloaded, you can call it up in Notepad or a spreadsheet program like Excel to read the contents. The garbage can icon to the right of the file will delete the file off of the micro SD card.

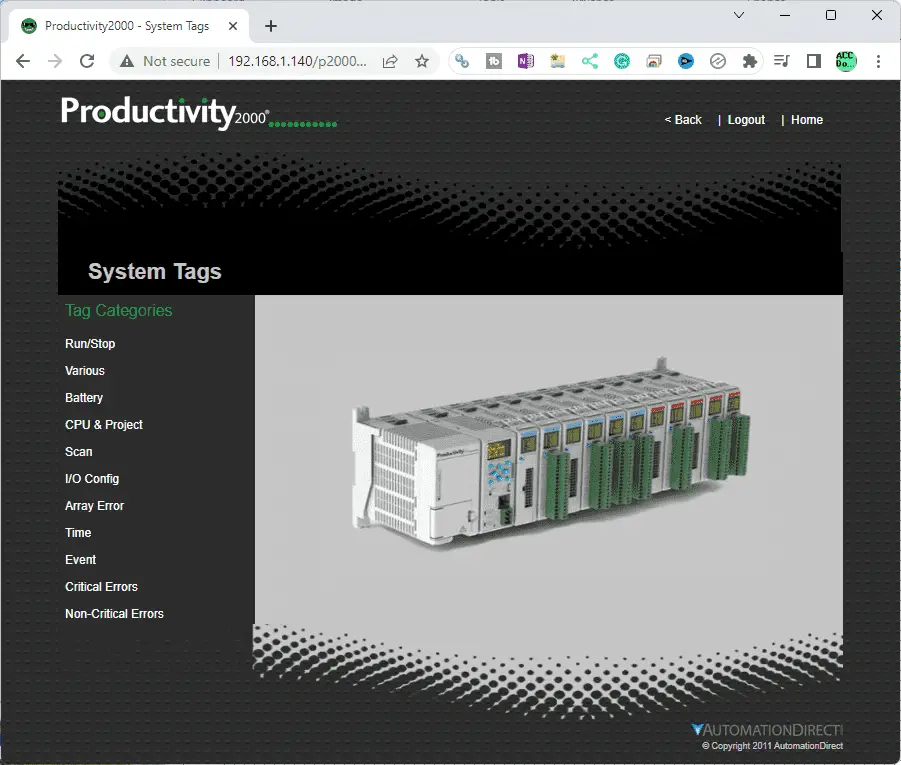

The System Data – Productivity Web Server

When the system data web page is displayed, you can choose several read-only memory information about the PLC.

Run/Stop – Current status of the PLC.

Various – Forces, I/O Error, Watchdog Timeout, Portable Memory Device Ready, Portable memory device Eject

Battery – Information on the battery in the PLC

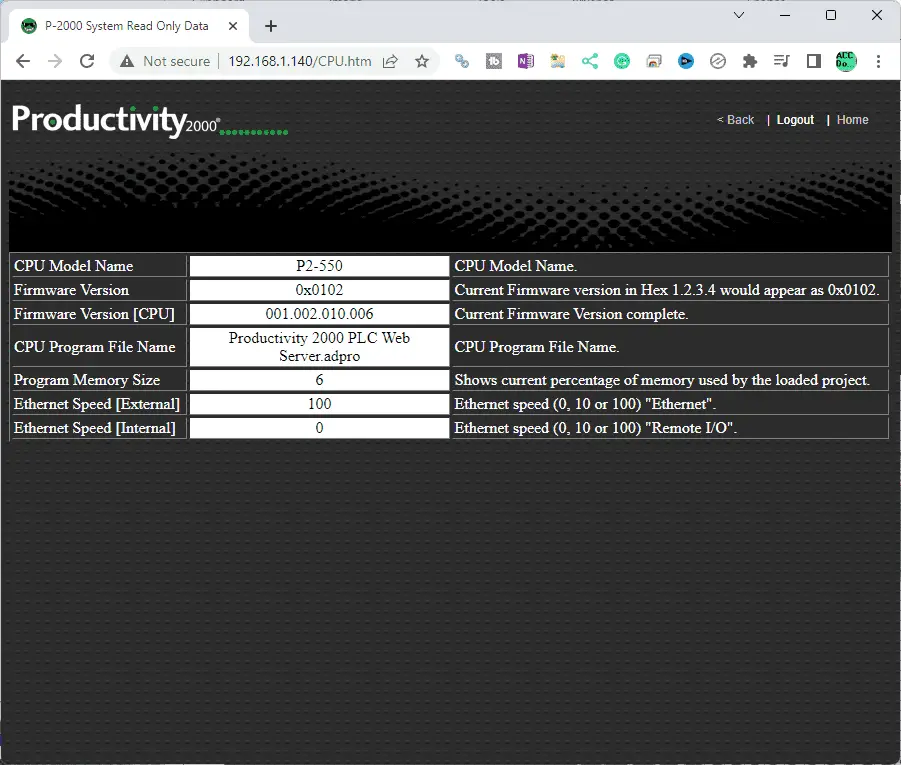

CPU & Project – Information on the CPU, Firmware, Current Program File Name, Program Memory Size, Ethernet Speeds

Scan – This will give you various information on the PLC scan

I/O Config – This will indicate if you have errors in the input, or output configuration

Array Error – This will show errors associated with arrays.

Time – Current real-time clock in the PLC.

Event – List events in the PLC like STOP, RUN, and New Programs Transferred.

Critical Errors – Current and previous critical errors that would stop the scan of the PLC.

Non-Critical Errors – Current and previous non-critical errors that would give an alarm on the PLC.

Here is an example of the CPU & Project web page information.

Download the P2000 Sample PLC program here.

Watch the video below to see the running and configuration of the web server on our Productivity 2000 Series PLC.

Productivity 2000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Overview (Features of the fully functional free software package for the Productivity Family of PLC (PAC) controllers)

Productivity Suite Programming Software (Free Download Link)

This software contains all the instructions and helps files for the Productivity Series.

Watch on YouTube: Productivity 2000 PLC Web Server (HTTP)

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, decimals, Hexadecimal, ASCII, and Floating points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.