The productivity series of PLCs has a built-in data logger. This accessible data logger will log up to 64 tag values on a USB (Micro SD) storage device connected to the CPU. The logs will be stored in CSV (Comma Separated Values) file format. Logging can be triggered by the rising edge transition of a Boolean tag (event) or configured to occur at regular intervals (scheduled).

A USB storage device should be generally connected if logging data. The CPU maintains an internal 73KB buffer for temporarily logging data while no USB storage device exists. Data in the buffer will not be retained through a power cycle. Let’s get started.

Previously in this Productivity 2000 series PLC, we have discussed the following:

P2000 Hardware Features – Video

Productivity Suite Software Install – Video

Communication (System Configuration) – Video

First Program – Video

Debug Mode – Video

PLC Program Documentation – Video

PLC CPU Display – Video

PLC Online Programming – Video

PLC Tag Database – Video

Ladder Logic Contacts – Video

Ladder Logic Outputs – Video

Timers – Video

Counter – Video

Productivity 2000 PLC Ladder Logic Math – Video

Data Handling Instructions

Part 1 – Video

Part 2 – Video

Array Functions

Part 1 – Video

Part 2 – Video

Part 3 – Video

P2000 Program Control – Video

Drum Sequencer Instructions – Video

Data Logger – Productivity 2000

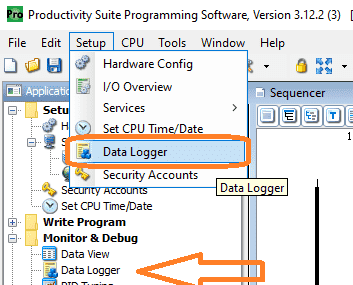

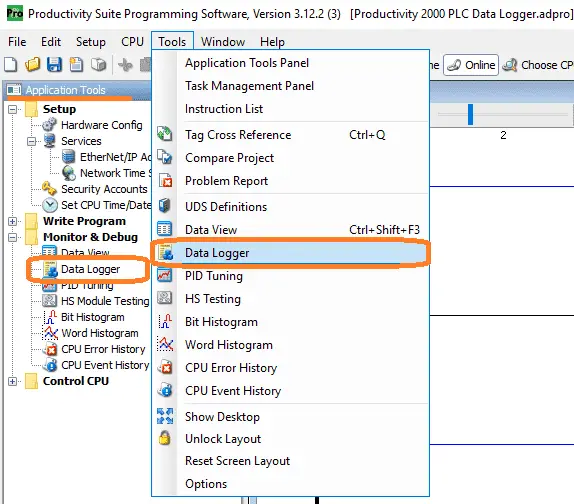

The data logger can be accessed in three different ways. Under the Monitor and Debug in the Applications Tools panel, you will see the Data Logger.

From the Main Menu, you can select Setup | Data Logger. The final method is also under the main menu, Tools | Data Logger.

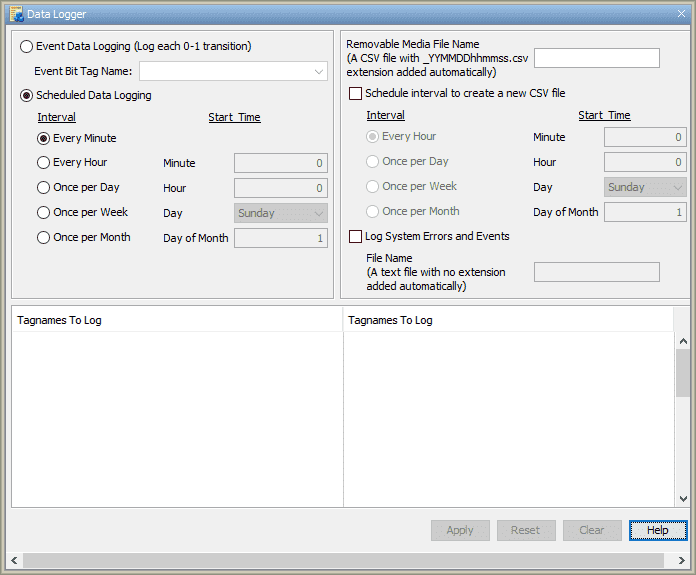

Event Data Logging – The logging will happen on the transition based on the ON status of the specific Boolean Tag (bit) specified in the Event Bit Tag Name.

Scheduled Data Logging – Select Scheduled Data Logging to log data based on a time interval. Select from the following:

Every Minute: Tag Data will be logged once per minute.

Every Hour: Tag Data will be logged once per hour at the designated minute (0 – 59).

Once per Day: Tag Data will be logged once per day at the appointed hour (0 – 23) and minute (0 – 59).

Once per Month: Tag Data will be logged once per month at the selected day (1 – 31), hour (0 – 23), and minute (0 – 59).

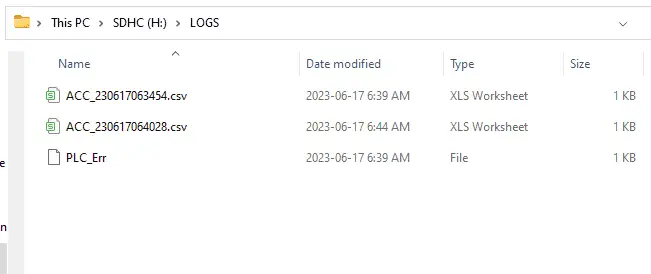

Removable Media File Name – Enter the prefix of the file name for the USB device. The name entered will always be appended by “-MMDDhhmm.csv,” where the time and date are the CPU time and date of the first entry. The CPU will create a “LOGS” folder and save the log file on the USB storage device.

Schedule interval to create a new CSV file – The name will be the same but with a new date and time stamp. A USB storage device must be installed during a scheduled CSV file name change to prevent buffered data loss. Select from the following:

Every Hour: A new CSV file will be created once per hour at the designated minute (0 – 59).

Once per Day: A new CSV file will be created once per day at the designated hour (0 – 23) and minute (0 – 59).

Once per Week: A new CSV file will be created once per week on the designated Day (Day of the week (Sunday … Saturday).

Once per Month: A new CSV file will be created once per month at the designated day (1 – 31), hour (0 – 23), and minute (0 – 59).

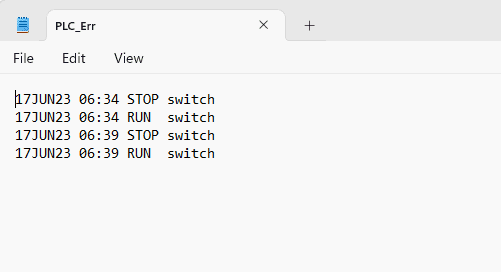

Log System Errors, Events & File Name – Select to log system errors and events and enter a file name for logging the systems errors and events. This function will create a text file containing system errors and events with the time and date the error or event occurred.

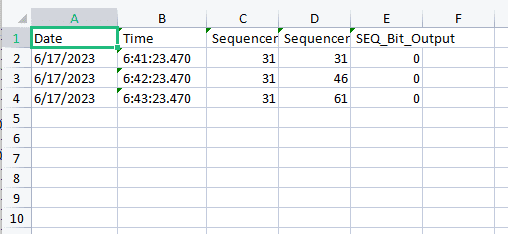

Tagnames To Log – Enter up to 64 Tag Names (32 per column) to be monitored. Each entry in the log file will include time and date fields.

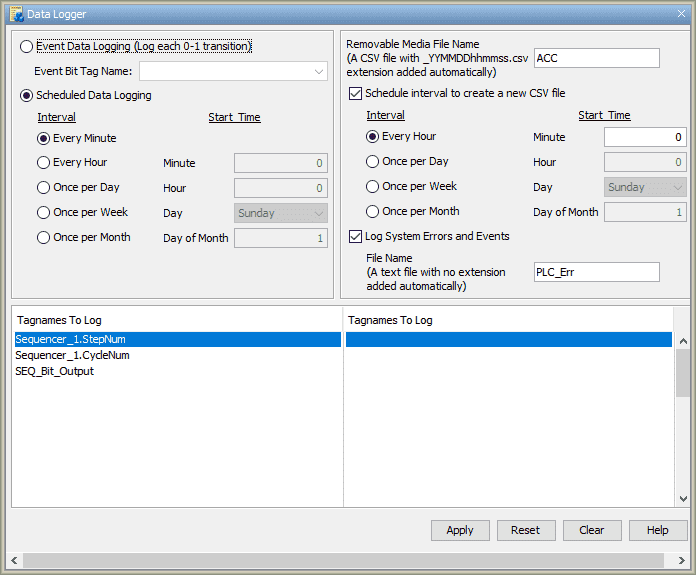

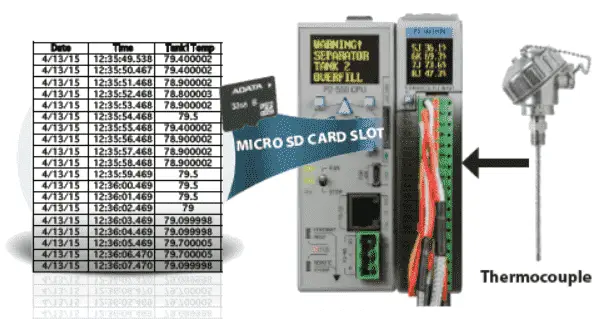

Our example will log the values every minute. (Scheduled logging) The file media name will be ACC. The _YYMMDDhhmmss.csv will be added to the file name. This represents the Year (YY), Month (MM), Day(DD), Hour (hh), Minute (mm), and Second (ss).

Every hour we will start a new CSV file. Log systems errors and events to a file called PLC_ERR.

Our tag names will be from our sequencer example discussed previously.

Hit Apply. We will then use the upper X in the corner to close the Data Logger window.

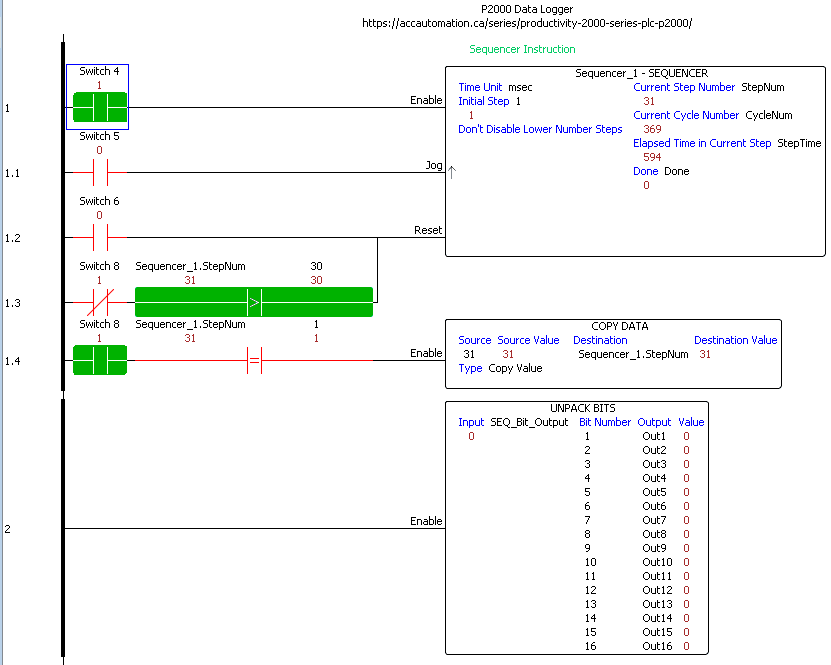

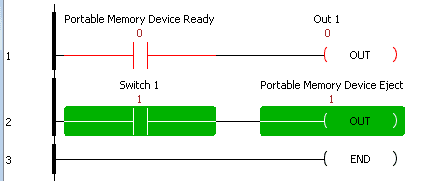

Here is the program that we created for the sequencer. Note: All of the logging is done without a lot of programming.

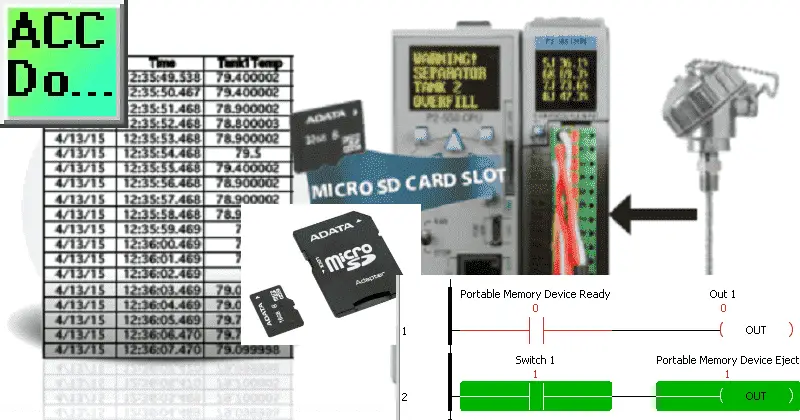

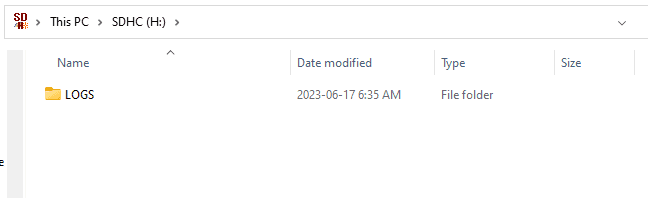

After running the program, we can turn the PLC to stop mode and remove the micro-SD card from the CPU unit. Looking at the files on the card, we will see the LOGS folder.

The logged information, error, and event files will be in the LOGS folder.

We see the three individual tags with the date and time stamp by opening the log file using a spreadsheet program like Excel.

Each record is separated by one minute, as we specified earlier.

The error and event file will show when the new program was put into the PLC, the RUN, and STOP events.

Portable Memory Device System Bits

There are two system bits for the portable memory device (PMD). The portable memory device ready is used to determine the status of the memory device.

The portable memory device eject is used to reject the memory device from the PLC without causing errors on the device.

This built-in feature easily accomplishes data Logging on the Productivity Series PLCs. You can access your log data securely from any connected web browser via the built-in web server or have the CPU email you the most current data logs directly with the Send Email instruction! This will be shown in future posts in the series.

Download the P2000 PLC program here.

Watch the video below for the data logger we created to run on our Productivity 2000 Series PLC.

Productivity 2000 Series PLC from Automation Direct

Overview Link (Additional Information on the Unit)

Configuration (Configure and purchase a system – BOM)

User Manual and Inserts (Installation and Setup Guides)

Productivity Suite Overview (Features of the fully functional free software package for the Productivity Family of PLC (PAC) controllers)

Productivity Suite Programming Software (Free Download Link)

This software contains all the instructions and helps files for the Productivity Series.

Watch on YouTube: Productivity 2000 PLC Data Logger and Logging

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, decimals, Hexadecimal, ASCII, and Floating points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is included when you subscribe to ACC Automation.