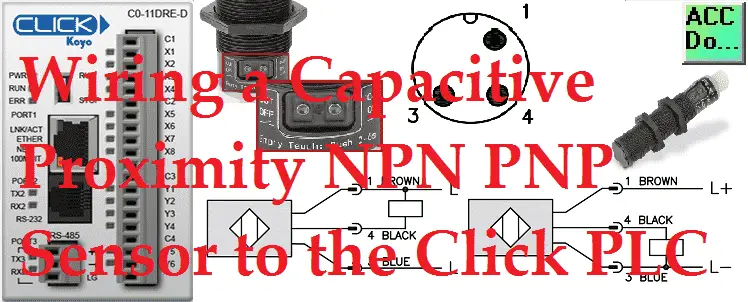

Capacitive Pushbutton Sensor Switch /Indicator

We will now look at the capacitive pushbutton sensor switch and indicator. Normal pushbuttons on a panel are usually a mechanical device. They can become “sticky” when too much dirt or oil is present. Capacitive push buttons do not have moving parts to stick, so the life expectancy is increased. Disinfectant sprays can be applied … Read more