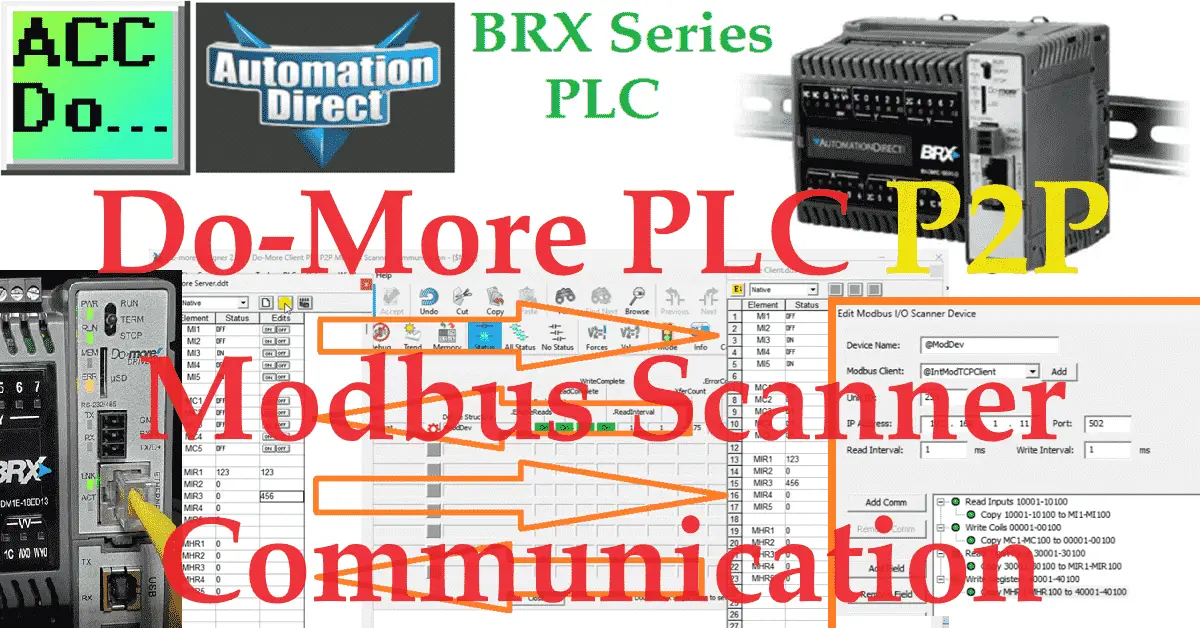

C2-NRED to BRX Do-More & Click PLCs: Modbus TCP!

We will now establish communication using Modbus TCP from the C2-NRED module to the Ethernet ports of the BRX Do-More and Click PLCs. Previously, we installed version 5.31.0 of the node-red-modbus-contrib package. We utilized the C2-NRED Package Compatibility Finder to locate and download this Node-RED package. Efficient PLC communication is essential for seamless operations. In … Read more