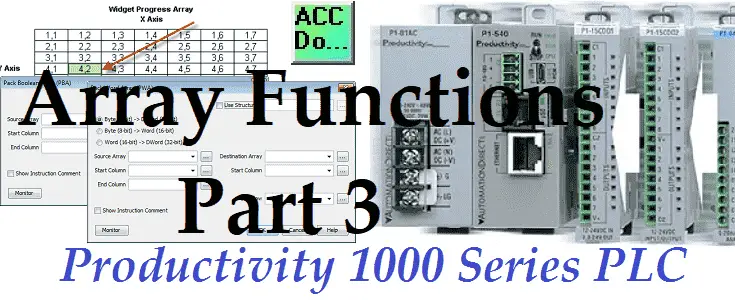

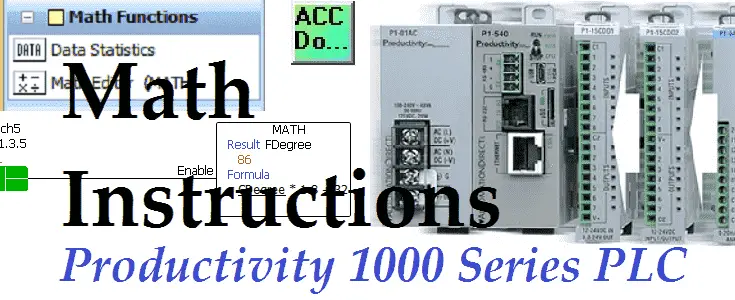

Productivity 1000 PLC Array Functions Part 3

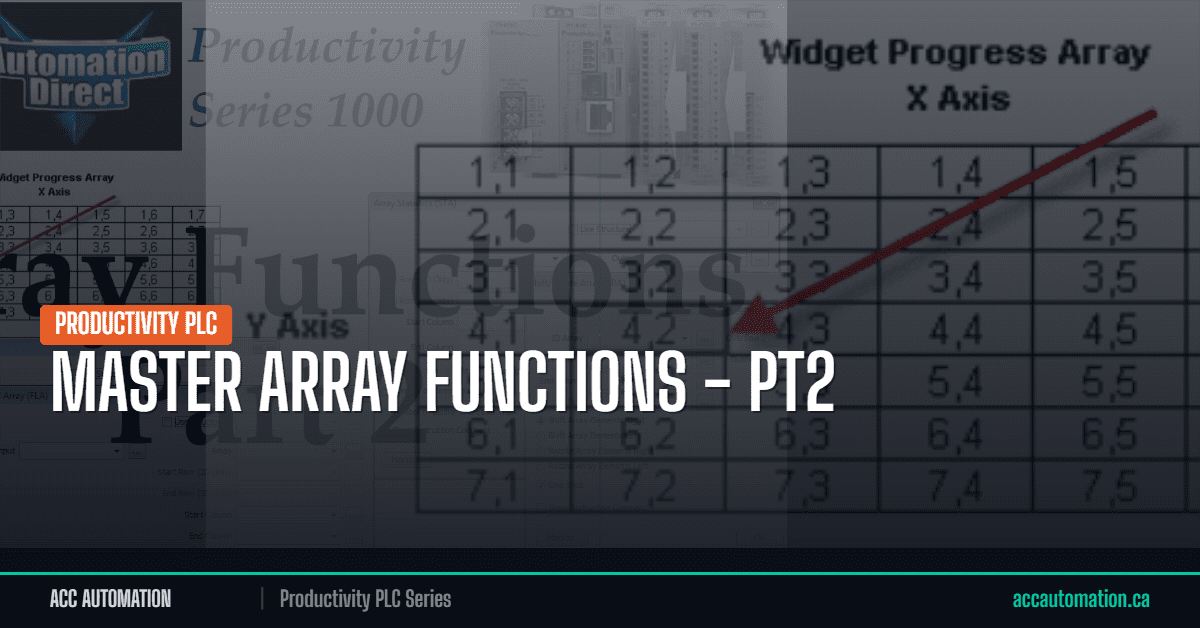

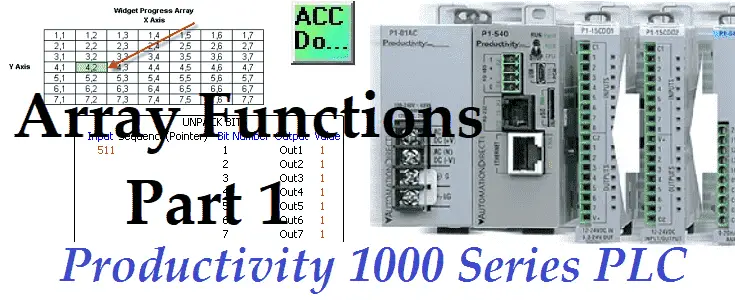

An array is a storage area for a group of common data type tags. They usually have some relationship with each other and need to be manipulated as a group. Previously we defined an array and use this in an indirect addressing program. It sequenced bits in an output card indirectly. We then looked at … Read more