FREE CLICK PLC Software: Is It REALLY That Easy?

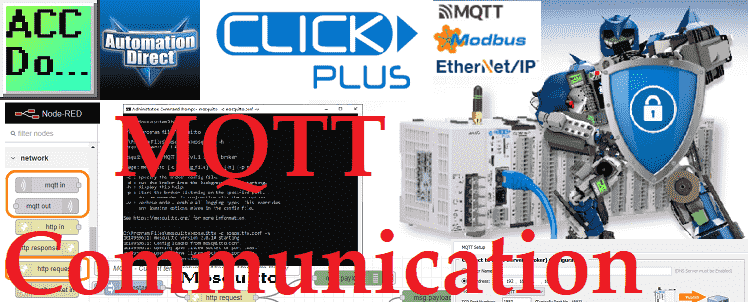

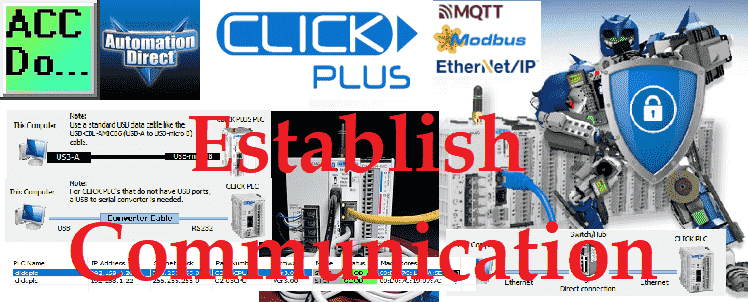

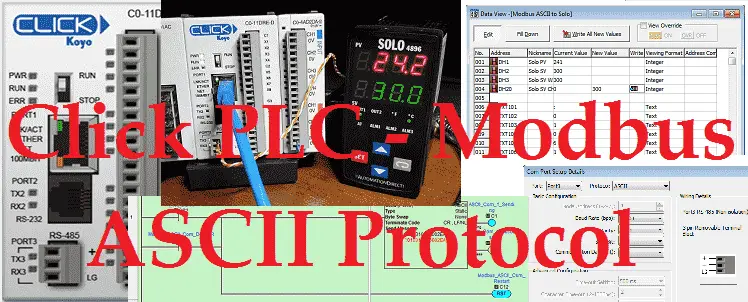

FREE CLICK PLC Software: Is It REALLY That Easy? This industrial-proven hardware and software have been around for 16 years. It has been regularly modified and updated to ensure it remains current and relevant. A Programmable Logic Controller (PLC) is a type of industrial control system used to automate machinery and processes. It is designed … Read more