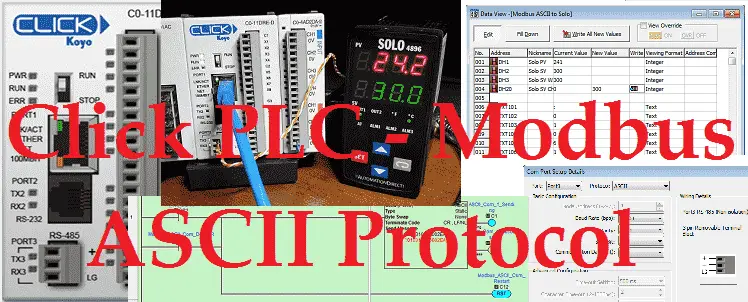

Click PLC Serial Communication Timing

Many questions come from serial communications using the Click PLC. Most of these questions deal with communication timing when using multiple send-and-receive instructions. We will show you how to deal with serial communication timing in the Click PLC. Receive and Send instructions will allow you to send and receive serial data to an external device. … Read more