ACC Automation

We would like to take a few minutes and reflect on the past, current and future of ACC Automation. 2017 has been our best year yet thanks to you. Your questions, comments and suggestions have helped us to build the site that you see today.

Thank you.

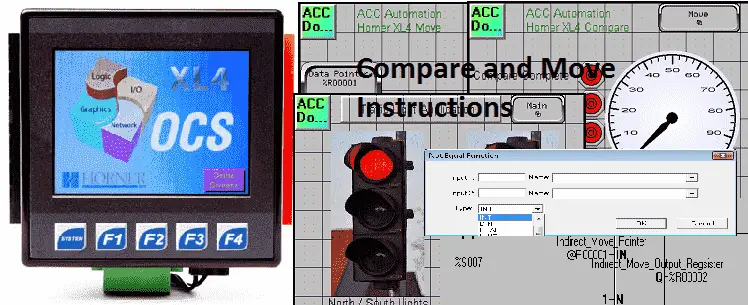

Starting off the year we finished our series on the Horner XL4 :

Horner APG XL4 Series

YouTube playlist: Horner XL4 All-in-one Controller (PLC + HMI)

https://accautomation.ca/horner-xl4-system-hardware/

This series on the Horner XL4 all-in-one controller (PLC) will go step by step through learning how to use this innovative unit.

There are several reasons why we are using the Horner XL4 Controller. Here are just a few.

– Investment is low for the hardware and the software is free

– Standalone PLC with built in I/O and HMI

– Communication ability – Ethernet Port, RS232, RS485 – support for protocols such as Modbus RTU, Modbus TCP, etc.

– Built in data logging functions

– Ability to expand the system with a variety of modules

Microsoft SQL Server Express 2014

Microsoft SQL Server Express 2014 is a free, edition of SQL Server this is ideal for learning and developing desktop, web and small server applications. The database size can be 10 gigabytes in size. SQL Server Express 2014 release includes the full version of SQL Server 2014 Management Studio. We used SQL Server 2014 to share the database on a network. The SQL Server database is ideal for applications such as data acquisition (data logging) from our PLC applications. We configured the SQL Server database so other computers can access this on the LAN (Local Area Network).

Here are the following post that were published:

Installing SQL Server Express 2014

Creating a Database in SQL Server Express 2014

Sharing a Database in SQL Server Express 2014

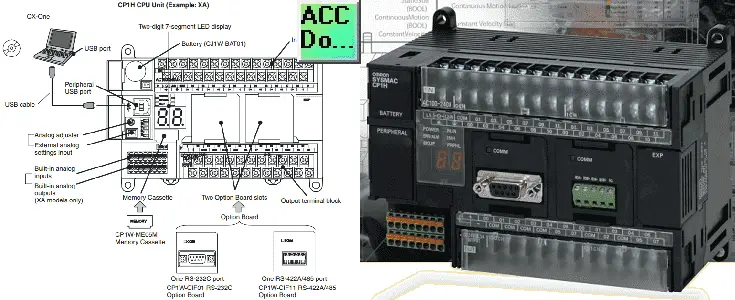

Omron CP1H Series PLC

YouTube playlist: Omron CP1H Series

https://accautomation.ca/omron-cp1h-system-hardware/

There are several reasons why we used the Omron CP1H Controller. Here are just a few.

– Standalone PLC with built in I/O

– Communication ability

– Ethernet Port, RS232, RS485

– support for protocols such as Modbus, Host Link, ASCII (No Protocol)

– Built in Analog inputs and outputs

– 4 axis control of motion

– 4 high speed counters

– powerful instruction set (similar to CS anc CJ series)

– Ability to expand the system with a variety of modules

The Omron CP1 series of programmable logic controllers consist of three different units. CP1E is the cost effective unit, CP1L is the high performing controller that can come with embedded Ethernet and the CP1H is the position control and comprehensive programmable logic controller. We will be looking a the CP1H for this series, but a majority of the information can be applied to the CP1E and the CP1L controllers as well.

During the year we also looked at the following additional items:

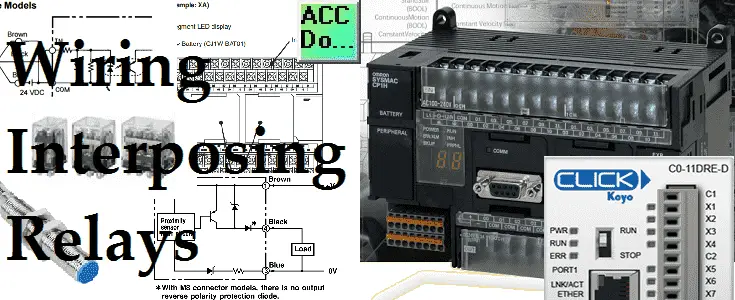

Wiring Interposing Relays

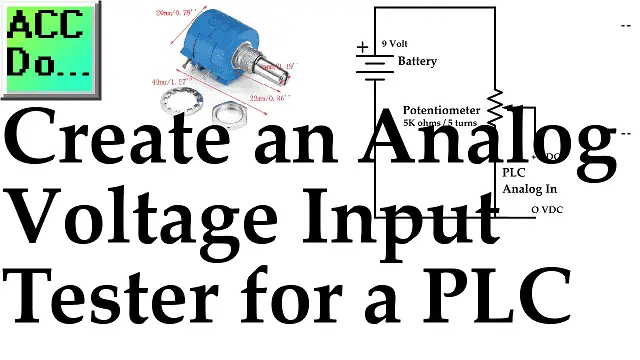

Create an Analog Voltage Input Tester for a PLC

Implementing the Omron Host Link Protocol (VB.Net)

Factory IO Introduction

FACTORY I/O is a 3D simulation for advanced PLC training. It works with a wide range of automation technologies including PLC, SoftPLC, PLC simulators, Modbus, OPC, and others. Here are some examples that we looked at in 2016:

PLC Fiddle – Online Editor and Simulator in your Browser

YouTube Video: PLC Fiddle

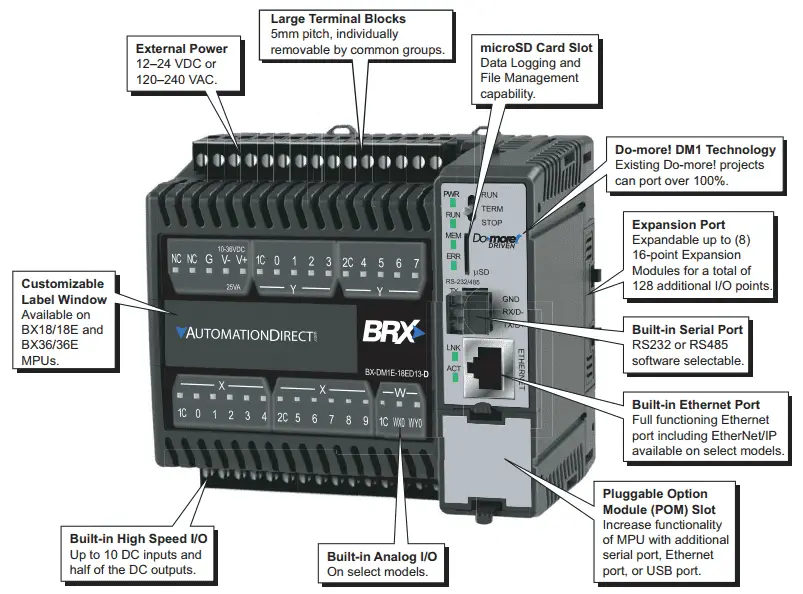

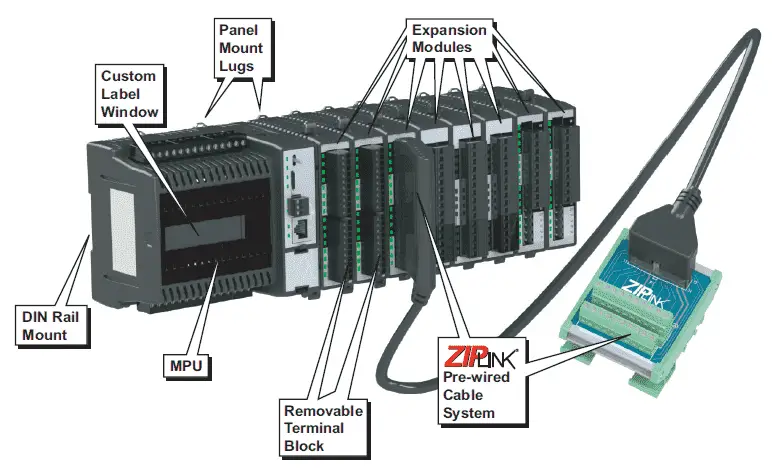

BRX Series PLC

YouTube playlist: BRX Series PLC – Automation Direct

https://accautomation.ca/brx-plc-system-hardware/

Currently we are in the process of this Automation Direct BRX Series PLC. We will continue in the New Year with additional communication and special function of this award winning controller.

2018 will prove to be an exciting time. We will look at a couple of new series.

Automation Direct Productivity 1000 Series

AdvancedHMI – Free VB.Net Human Machine Interface that will run on Visual Studio

More examples of Factory IO – 3D simulation of your process

As always we will be answering your questions and applications so you can quickly implement your control solution.

Watch on YouTube: ACC Automation 2017 Review

If you have any questions or need further information please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLC’s are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII and Floating Point.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.