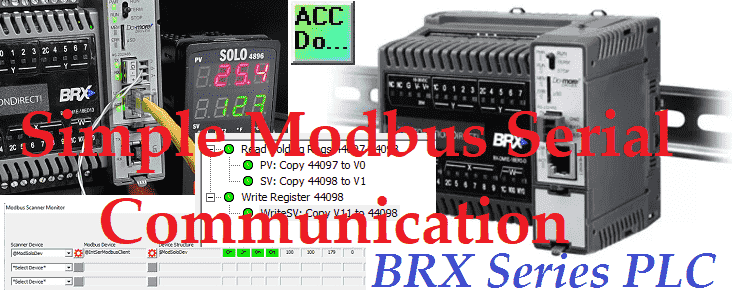

The newest Do-More Designer Programming Software (2.9) version includes a Modbus I/O Scanner. This Modbus scanner will simplify Modbus RTU serial communications to any device. Communications are done independent of the PLC scan time and will have little or no ladder logic for the program.

We will be communicating to a Solo process temperature controller via Modbus RTU RS485. (twisted pair) Setting up the Modbus IO scanner and reading the present value (PV) and set value (SV) of the Solo. We will also write the set value (SV) located within the BRX Do-More controller. Communications will happen without using any ladder logic code. Let’s get started.

We will be communicating to a Solo process temperature controller via Modbus RTU RS485. (twisted pair) Setting up the Modbus IO scanner and reading the present value (PV) and set value (SV) of the Solo. We will also write the set value (SV) located within the BRX Do-More controller. Communications will happen without using any ladder logic code. Let’s get started.

Previously in this BRX series PLC, we have discussed:

System Hardware – Video

Unboxing – Video

Installing the Software – Video

Establishing Communication – Video

Firmware Update – Video

Numbering Systems and Addressing – Video

First Program – Video

Monitoring and Testing the Program – Video

Online Editing and Debug Mode – Video

Timers – Video

Counters – Video

High-Speed IO – Video

Compare Instructions – Video

Math Instructions – Video

Program Control – Video

Shifting Instructions – Video

Drum Instruction – Video

Serial Communication – Modbus RTU to Solo Process Temperature Controller – Video

Data Logging – Video

Email – Text SMS Messaging Gmail – Video

Secure Email Communication Video

AdvancedHMI Communication – Modbus TCP – Video

Analog IO – System Configuration – Video

HTTP JSON Instructions – Video

Analog Dusk to Dawn Program – Video

INC DEC 512 Registers for DMX512 – Video

PID with PWM Output – Video

PID Ramp Soak Profile – Video

Do-More Simulator MQTT Publish / Subscribe – Video

BRX Do-More PLC MQTT Communications – Video

Stride Field Remote IO Modules Modbus TCP Ethernet

– Unboxing SIO MB12CDR and SIO MB04ADS Video

– Powering and Configuring Video

BRX Do-More PLC to Stride Field IO Modbus TCP – Video

BRX Do-More PLC Ethernet Remote IO Controller BX-DMIO

– Unboxing BX-DMIO Video

– Configuration and Programming Video

Modbus RTU TCP Remote IO Controller BX-MBIO

– Hardware Video

– Powering and Configuring Video

BRX Do-More PLC to Modbus Remote IO Controller BX-MBIO – Video

Modbus ASCII Protocol – Video

Peerlink Ethernet Communication – Video

HTTP Web Server – Video

Dynamic Web Pages – Video

BRX Do-More PLC FTP Client Get Put – Video

Do-More Designer Element Browser – Video

BRX Do-More PLC High-Speed Input Counter – Video

BRX Do-More PLC High-Speed Input Timer – Video

BRX Do-More PLC High-Speed Input Pulse Catch – Video

Our entire BRX Do-More series can be found here.

The programming software and manuals can be downloaded free from the Automation Direct website.

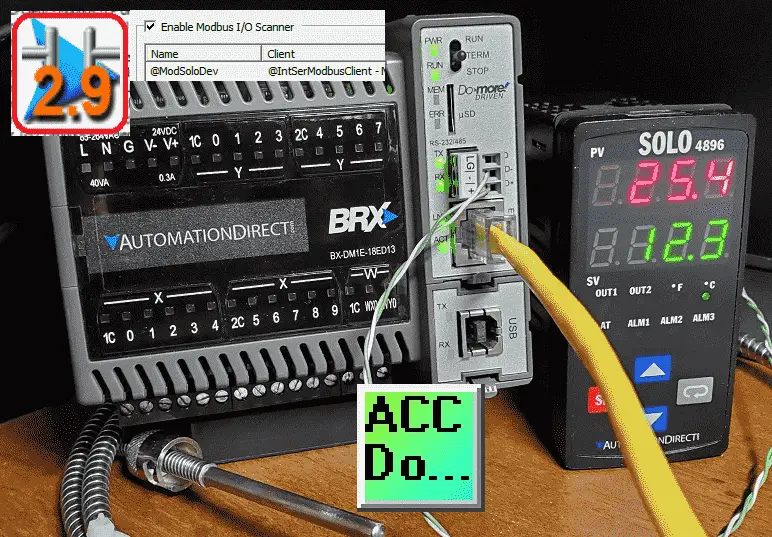

Watch the video below to see the operation of the Modbus IO scanner on the BRX Do-More PLC. This will be Modbus RTU (RS485) to a Solo Process Temperature Controller.

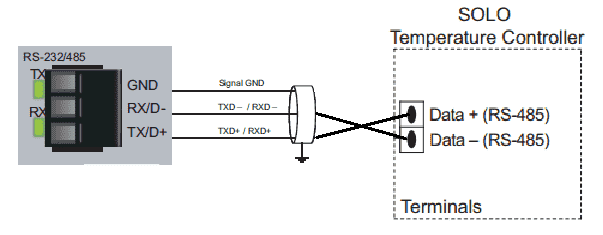

Communication RS485 Wiring Solo to BRX Do-More PLC

RS485 is a two-wire serial communication media, and Modbus RTU will be the protocol used. This protocol is a master/slave type of configuration. The BRX will be the master and will communicate with the Solo slave. There can be only one master on the serial network and up to 247 slaves with a repeater. Without a repeater, you can connect 32 slaves with RS485. These can be different devices.

RS485 is a two-wire serial communication media, and Modbus RTU will be the protocol used. This protocol is a master/slave type of configuration. The BRX will be the master and will communicate with the Solo slave. There can be only one master on the serial network and up to 247 slaves with a repeater. Without a repeater, you can connect 32 slaves with RS485. These can be different devices.

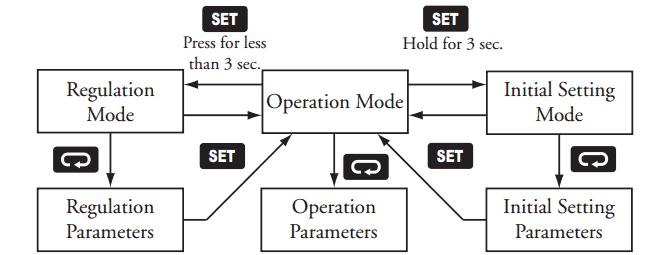

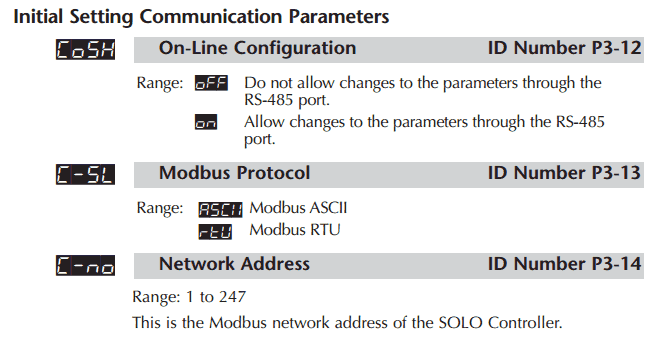

Communication Setting for the Solo Process Temperature Controller

The solo process temperature controller needs to be set up before we can communicate with it. The default setting is ‘Off’ for the On-Line Configuration. Here is the way to change into the different modes in the Solo.

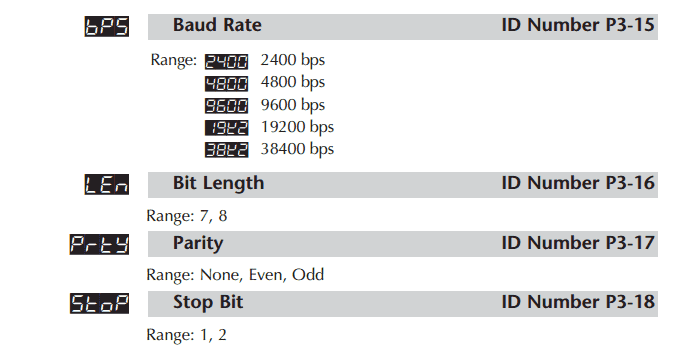

In the Initial Setting Mode, we will change the on line configuration to on and make the changes to the Modbus settings: 9600 Baud, Even, 8 Data Bits, 1 Stop Bit, Modbus RTU Format. We will leave the default unit number as 1.

In the Initial Setting Mode, we will change the on line configuration to on and make the changes to the Modbus settings: 9600 Baud, Even, 8 Data Bits, 1 Stop Bit, Modbus RTU Format. We will leave the default unit number as 1.

Our controller is now set to communicate.

Our controller is now set to communicate.

Download the documentation, configuration, and monitoring software at the following URL link:

http://support.automationdirect.com/products/solo.html

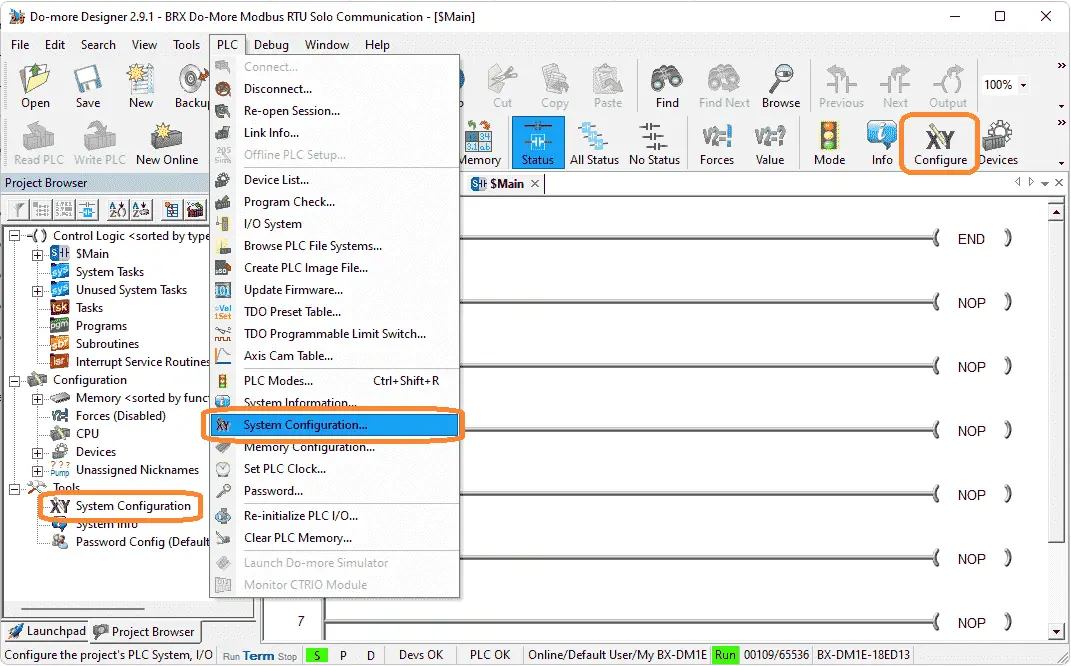

Configuration of the BRX PLC Serial RS485 Port

We will now set up the RS485 serial communication port with the specifications that match the setting of the Solo controller.

Select System Configuration… under the main menu | PLC, or select the icon on the main menu. Alternatively, you can also choose System Configuration under the Tools menu of the Project Browser window.

Select System Configuration… under the main menu | PLC, or select the icon on the main menu. Alternatively, you can also choose System Configuration under the Tools menu of the Project Browser window.

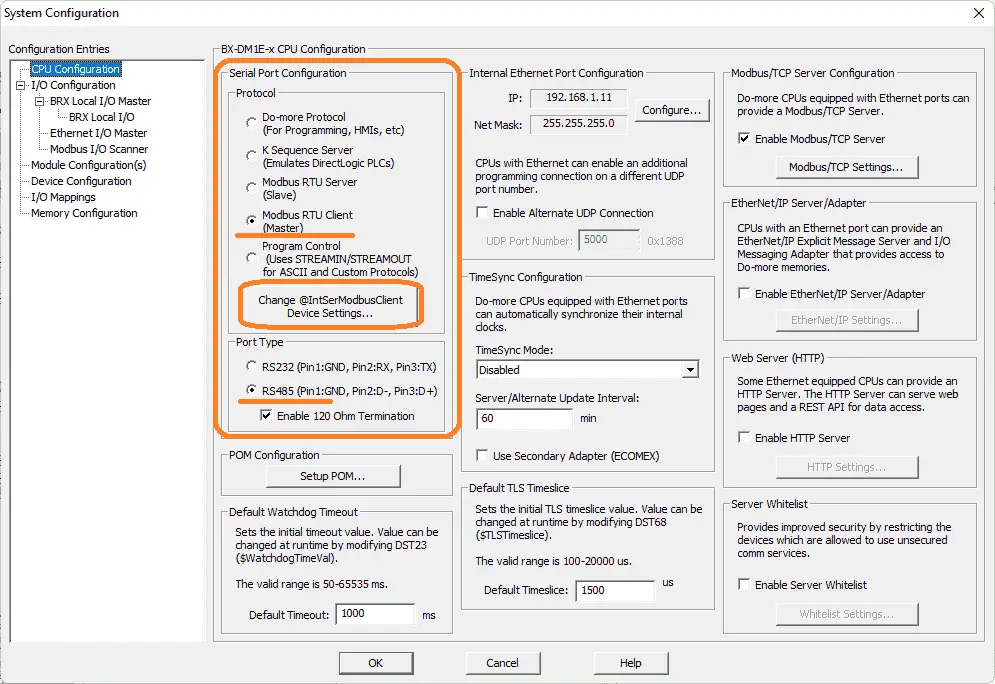

The CPU Configuration will be selected as the default display under configuration entries on the left side of the system configuration window.

The CPU Configuration will be selected as the default display under configuration entries on the left side of the system configuration window.

Select Modbus RTU Client (Master) as the protocol. Select RS485 as the port type and enable the 120 Ohm termination resistor.

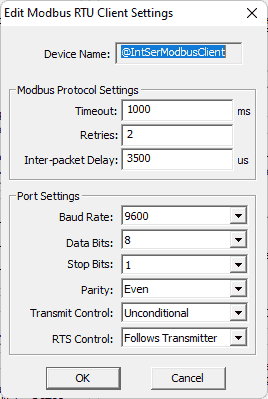

@IntSerModbusClient is the default name for this Modbus Client in the BRX PLC. Select the Change @IntSerModbusClient Device Settings… button.

Enter the Modbus settings: 9600 Baud, Even, 8 Data Bits, 1 Stop Bit to match our Solo Process Temperature Controller. Select OK. This will bring us back to our system configuration window.

Enter the Modbus settings: 9600 Baud, Even, 8 Data Bits, 1 Stop Bit to match our Solo Process Temperature Controller. Select OK. This will bring us back to our system configuration window.

Modbus IO Scanner Configuration

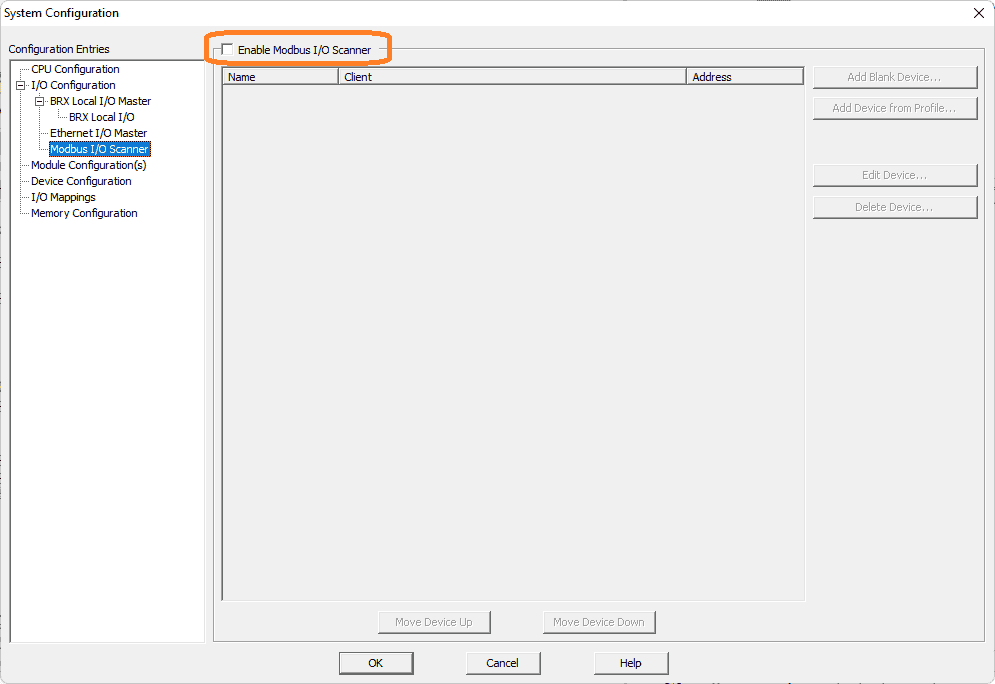

Select the Modbus I/O Scanner. This is located under the BRX Local IO Master in the IO Configuration of the system configuration window.

Select enable Modbus I/O Scanner.

Select enable Modbus I/O Scanner.

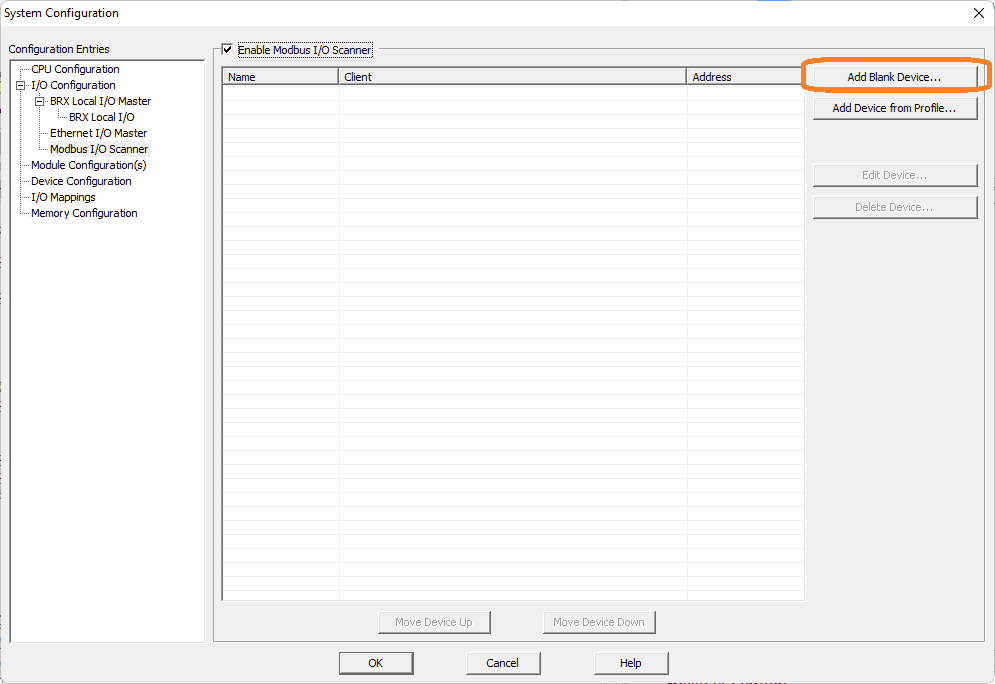

Several profiles have been set up in the software. These profiles will allow you to use what has been proven in the field. The Solo Process Temperature Controller does not currently have a profile. Select Add Blank Device…

Several profiles have been set up in the software. These profiles will allow you to use what has been proven in the field. The Solo Process Temperature Controller does not currently have a profile. Select Add Blank Device…

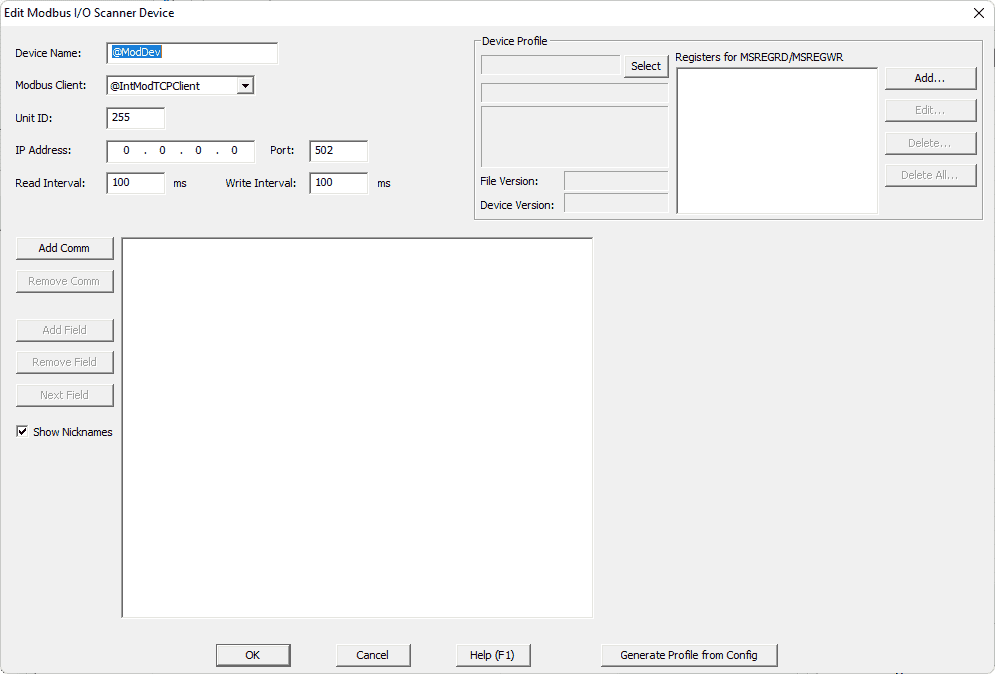

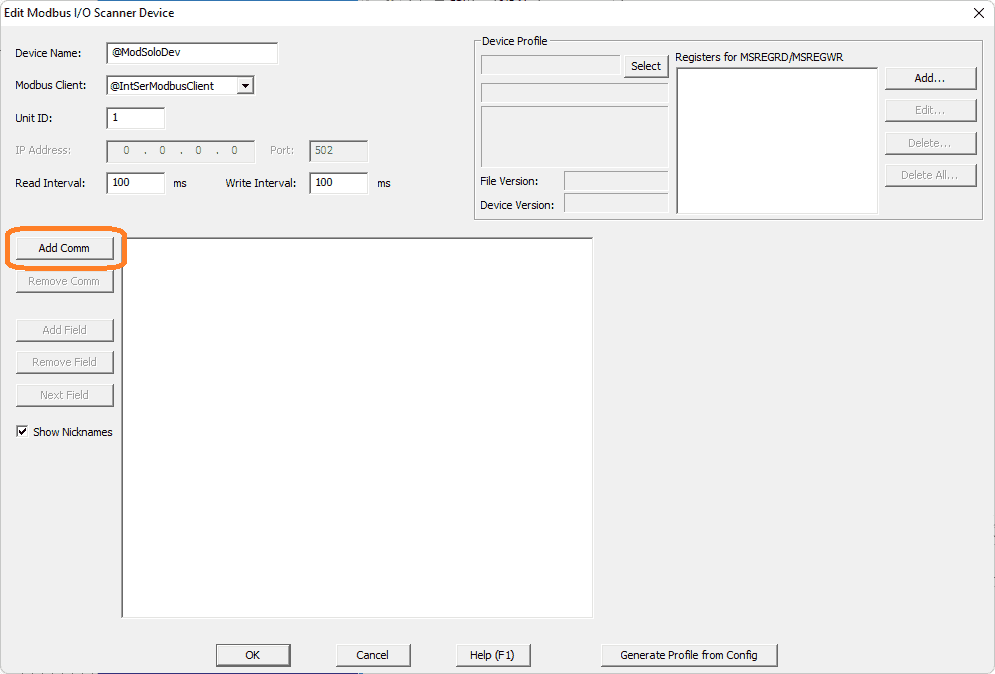

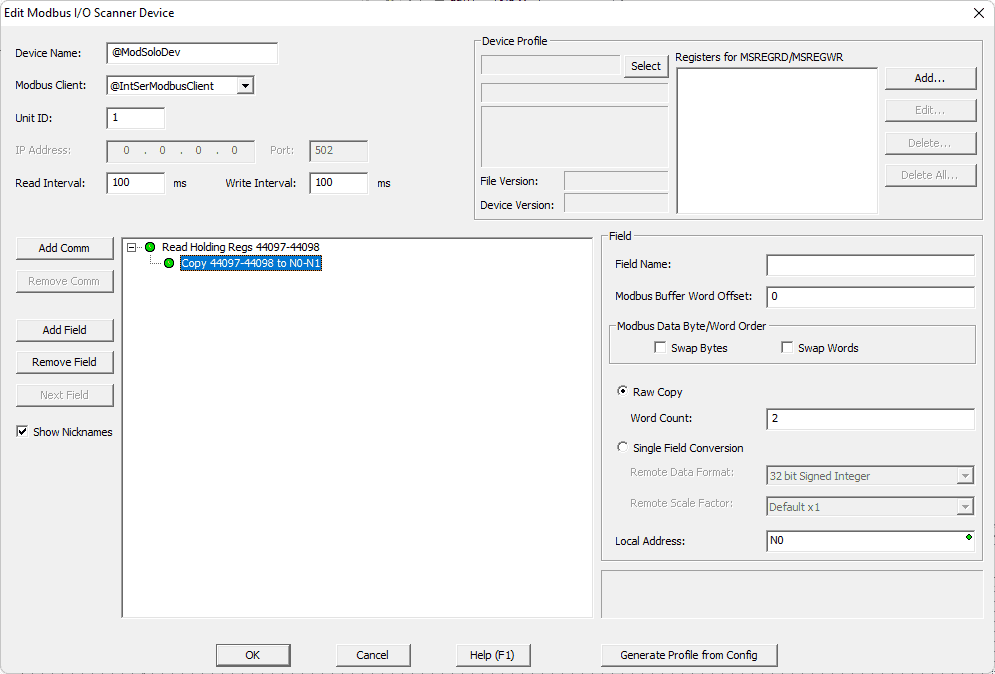

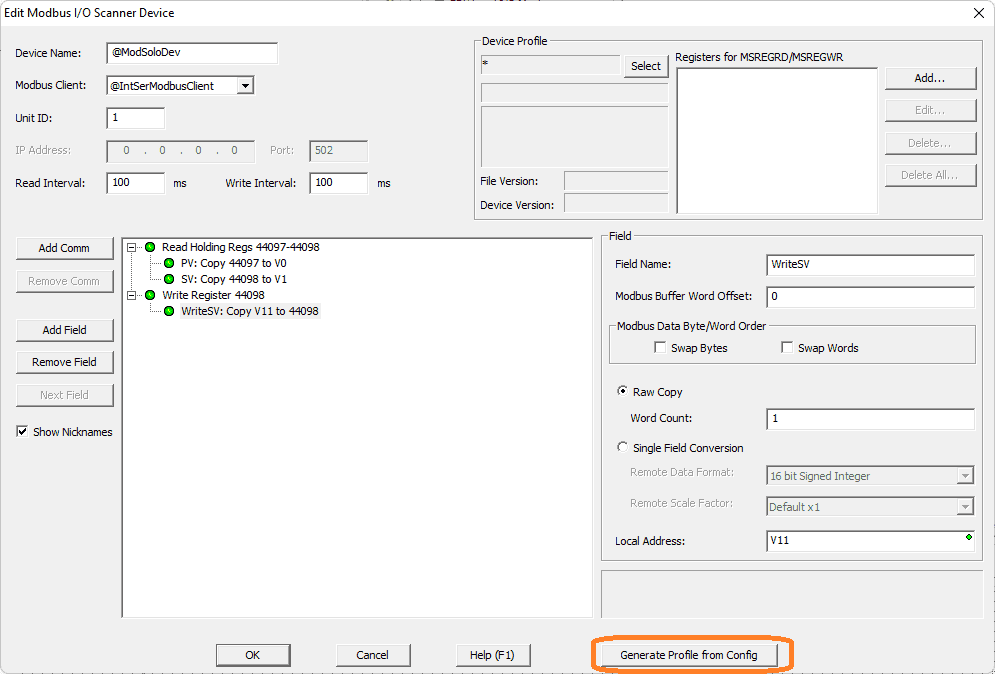

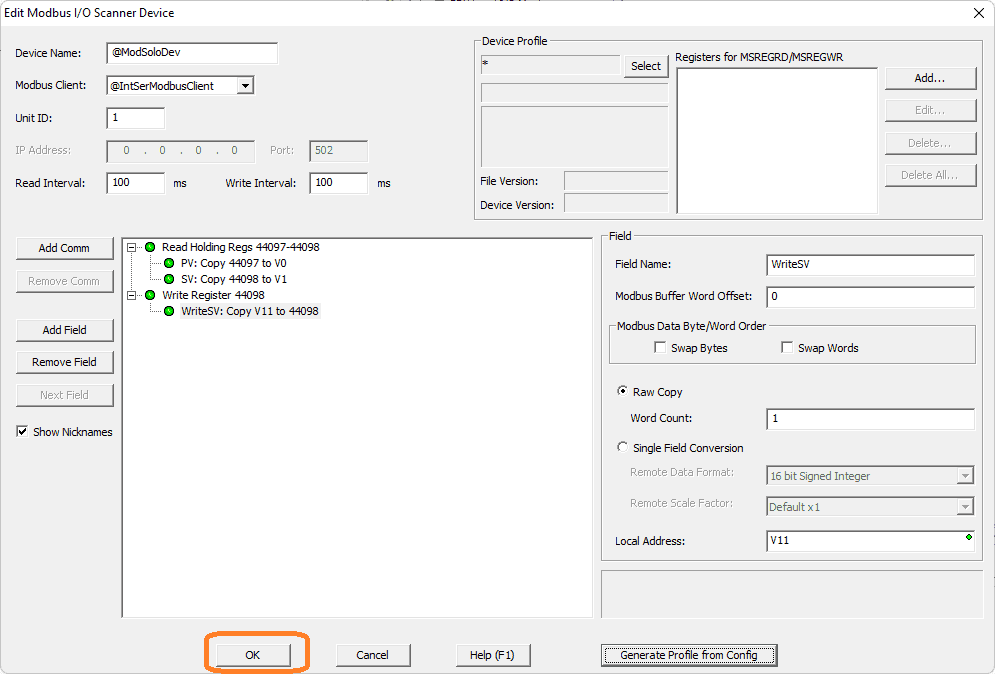

Device Name: We will change this to @ModSoloDev, so we know what it is doing.

Device Name: We will change this to @ModSoloDev, so we know what it is doing.

Modbus Client: Change this to the @IntSerModbusClient port that we set up above.

Unit ID: 1 – This is set for our Solo controller.

Read Interval: 100 ms – This is the reading interval independent of the BRX PLC scan time. We will leave this a 100-millisecond default. (10 times per second)

Write Interval: 100 ms – This is the writing interval independent of the BRX PLC scan time. We will leave this a 100-millisecond default. (10 times per second)

Select the Add Comm button.

Select the Add Comm button.

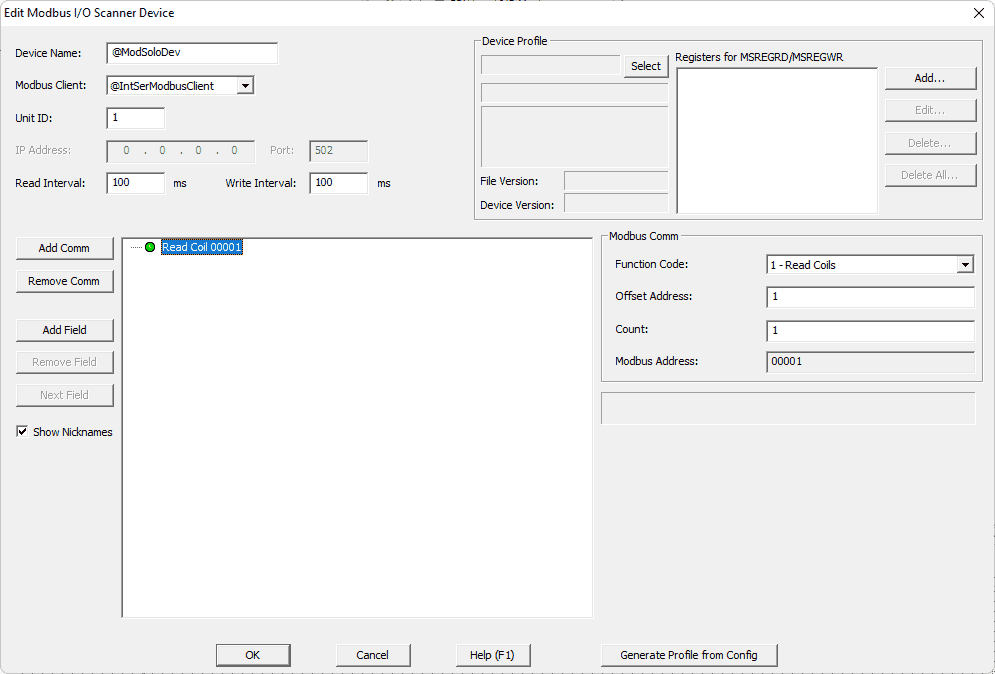

The Read Coil 00001 shows up as a default. The settings on the right-hand side will set the Modbus communication. The links below will explain these Modbus function codes. The Modbus addresses for the Solo process temperature controller can be found in chapter 7 of the manual. See the link below.

The Read Coil 00001 shows up as a default. The settings on the right-hand side will set the Modbus communication. The links below will explain these Modbus function codes. The Modbus addresses for the Solo process temperature controller can be found in chapter 7 of the manual. See the link below.

Set the function code to 3 – Read Holding Registers

Set the function code to 3 – Read Holding Registers

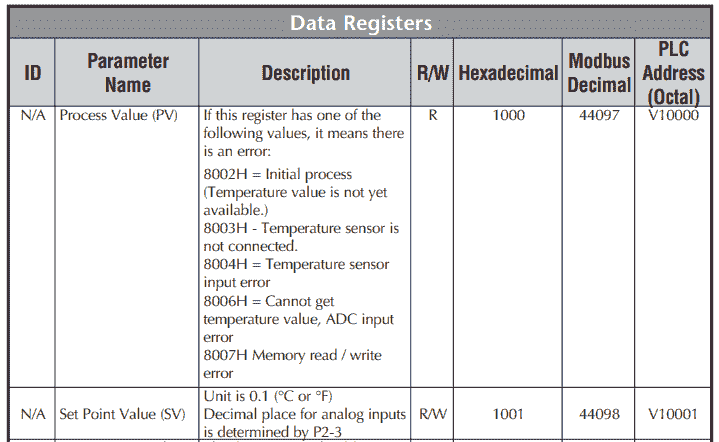

The Offset Address will be 4097.

The count is the number of registers to read. Set this for two so we will read both the present value (PV) and set value (SV).

Based on the function code, you will see the Modbus address of 44097-44098. This matches the Modbus Decimal address from the chart above.

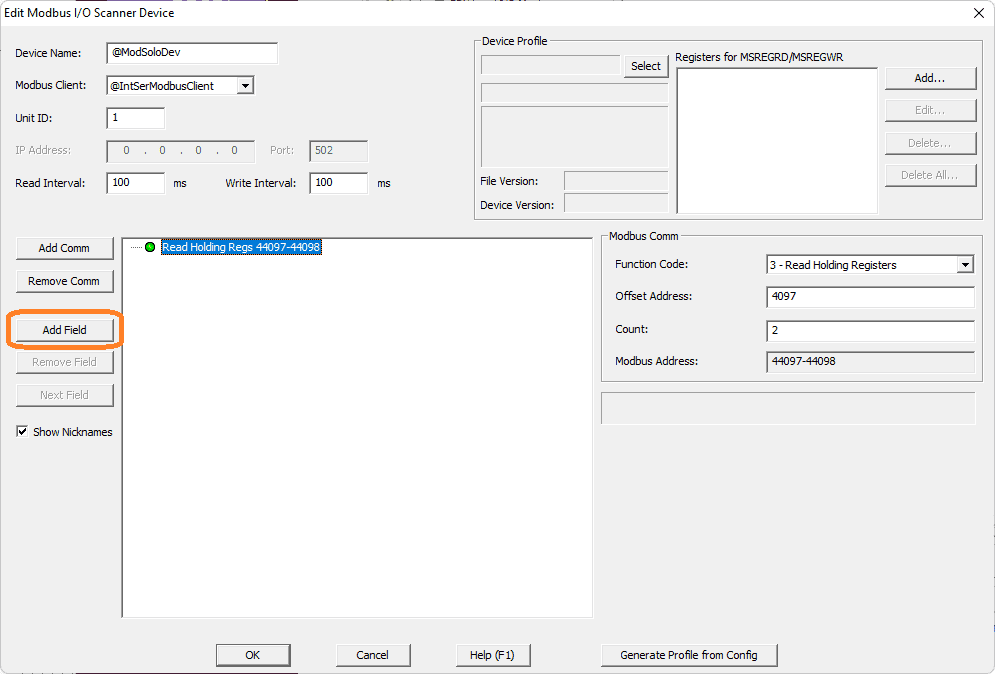

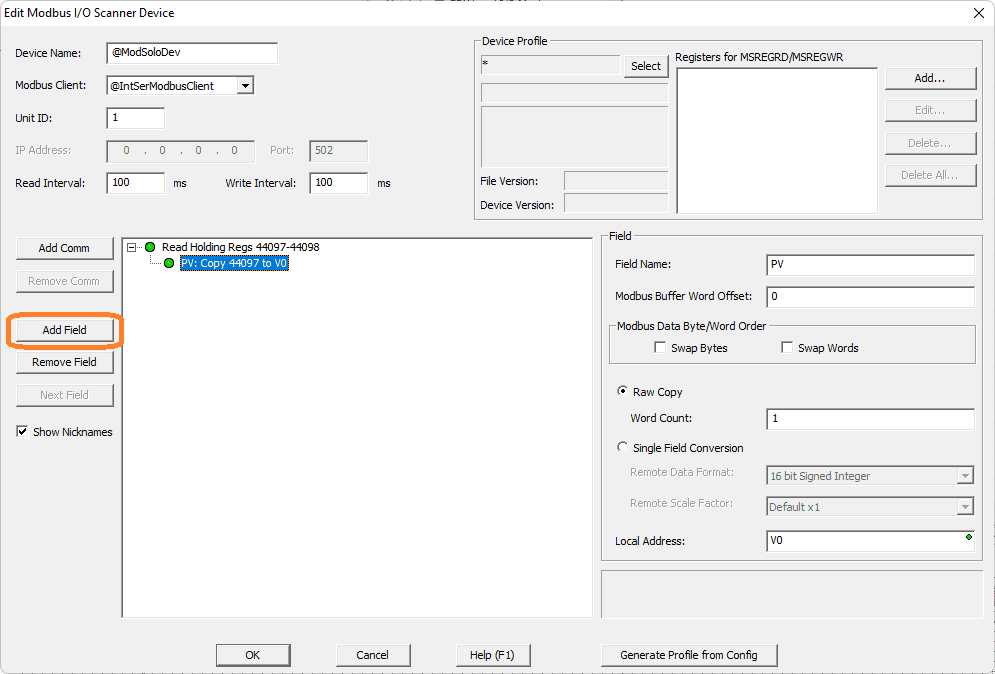

Select Add Field. The field will manipulate the data read from the Modbus Solo.

Select Add Field. The field will manipulate the data read from the Modbus Solo.

Set the field name to PV (Present Value). Since the PV value is a 16-bit single word, we will put the word count as one and keep the raw copy. The Modbus buffer word offset will be left as the default 0 because this is the first word being read from the Solo.

Set the field name to PV (Present Value). Since the PV value is a 16-bit single word, we will put the word count as one and keep the raw copy. The Modbus buffer word offset will be left as the default 0 because this is the first word being read from the Solo.

Note: Depending on the information coming from the Modbus device, we can modify it to suit the data it represents. Example: 32-bit float number.

Set the local address to V0.

Select the Add Field button again.

Select the Add Field button again.

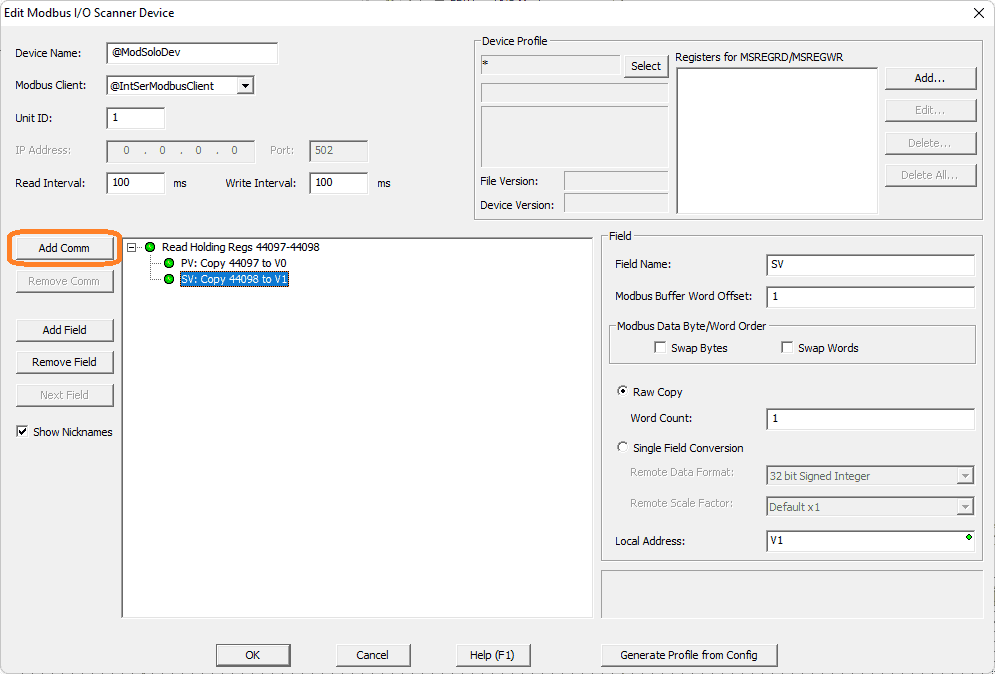

Our second Modbus address is the set value SV. We will place this in address V1 of the BRX PLC. The Modbus buffer word offset is 1, and we have a raw copy of the 1-word count.

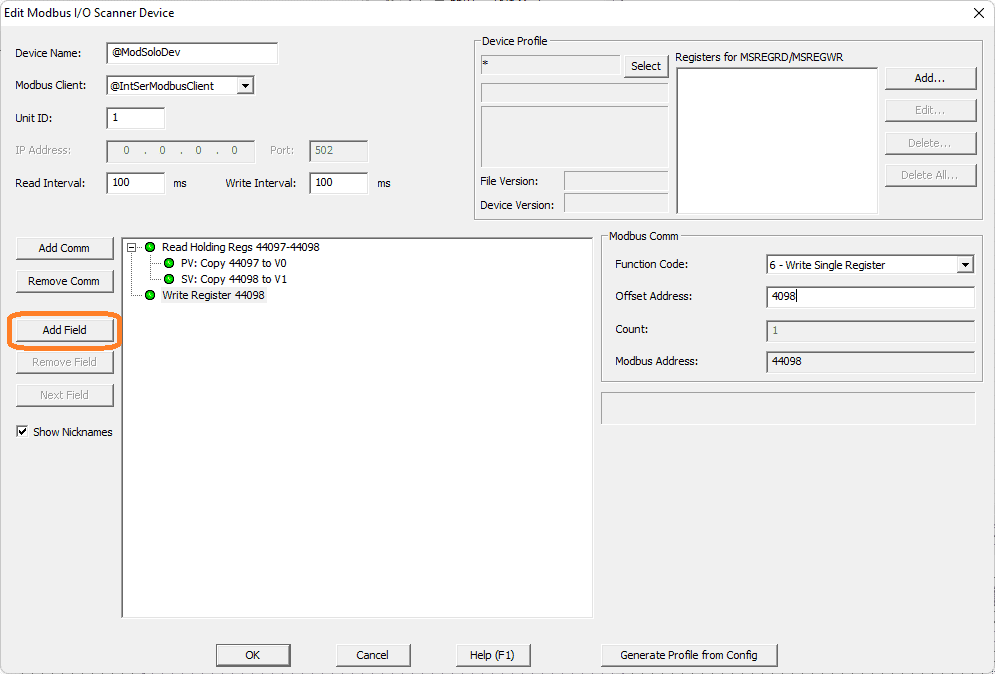

Select the Add Comm button again. We want to use the function code 6 – Write Single Register. The offset will be 4098, making the Modbus Address 44098.

Select the Add Comm button again. We want to use the function code 6 – Write Single Register. The offset will be 4098, making the Modbus Address 44098.

Select Add Field.

The field name will be “WriteSV.” Using the raw copy word count of 1, we will use the value in V11 to write to our Solo controller.

The field name will be “WriteSV.” Using the raw copy word count of 1, we will use the value in V11 to write to our Solo controller.

Select the Generate Profile from the Config button.

Select the Generate Profile from the Config button.

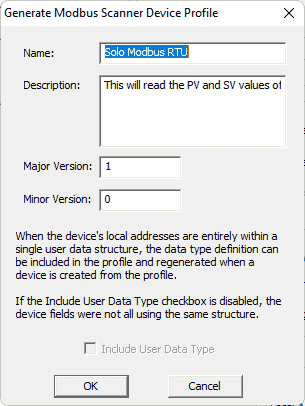

You can provide a name and description of the configuration. Select OK.

You can provide a name and description of the configuration. Select OK.

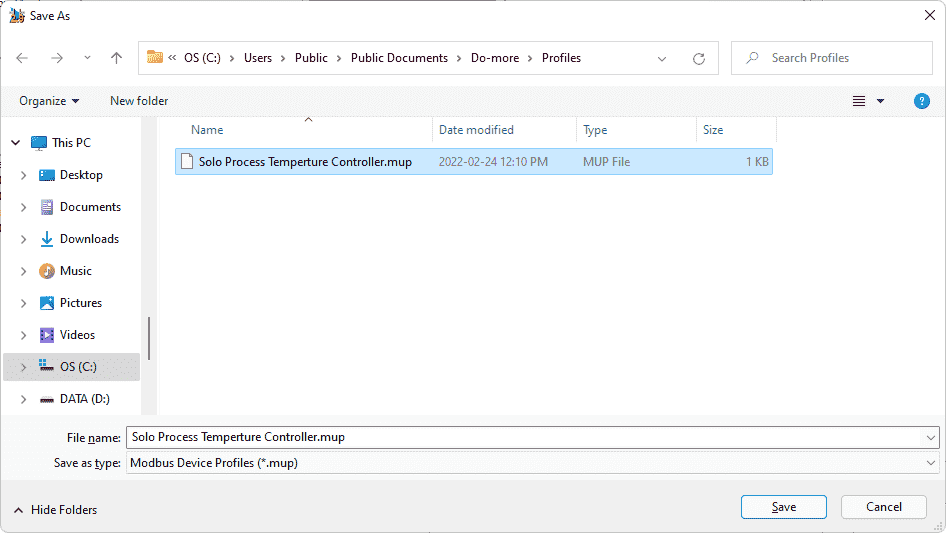

Name the Modbus Device Profile. The extension will have a “.mup.” Select Save.

Name the Modbus Device Profile. The extension will have a “.mup.” Select Save.

Our configuration has now been saved.

Our configuration has now been saved.

Select OK.

Select OK.

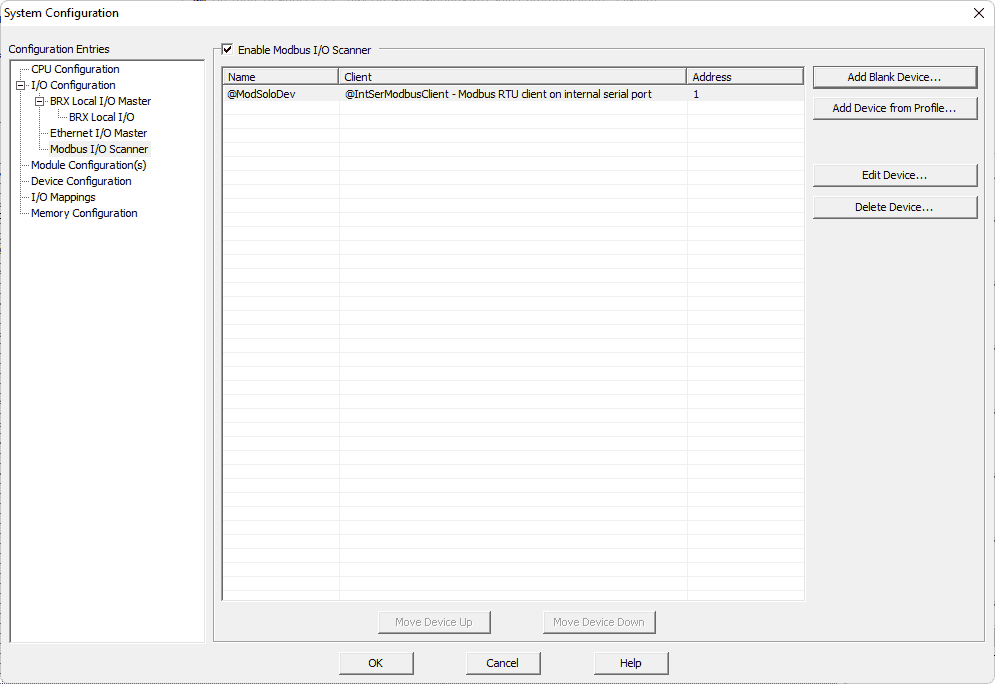

Our Modbus I/O Scanner can now be seen in the system configuration window.

Our Modbus I/O Scanner can now be seen in the system configuration window.

Select OK to close the window.

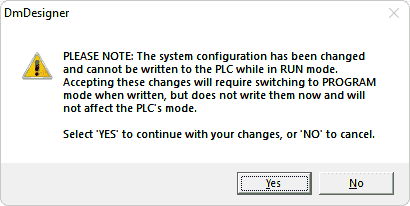

Since we have changed the BRX PLC system configuration, a warning message will be displayed. Select Yes.

Since we have changed the BRX PLC system configuration, a warning message will be displayed. Select Yes.

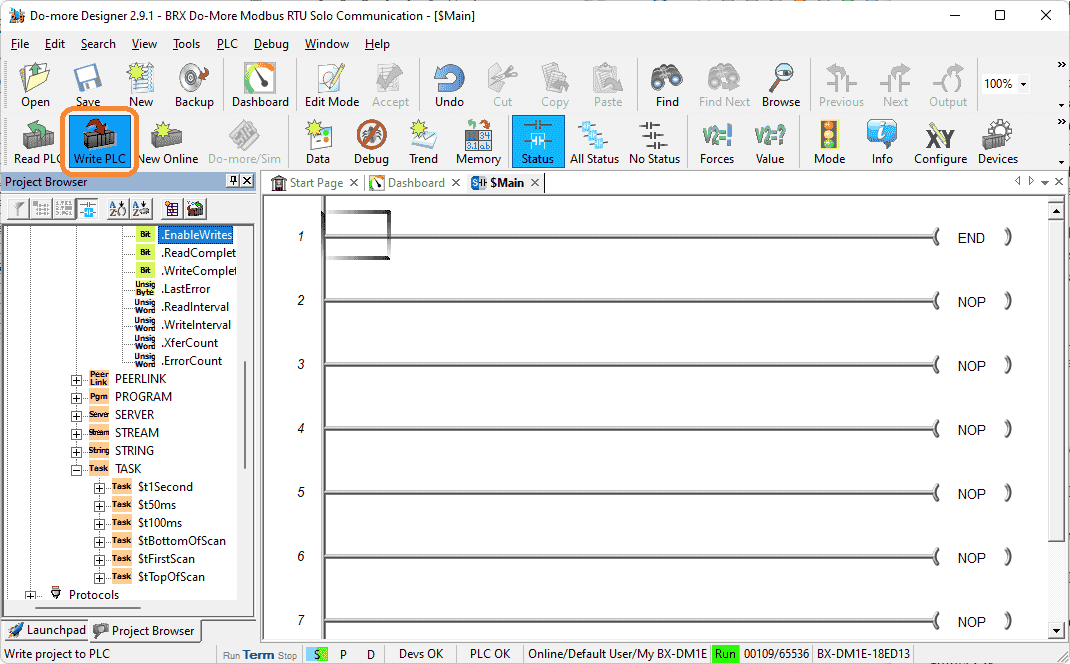

Write the PLC project and configuration to the connected PLC.

Write the PLC project and configuration to the connected PLC.

Monitoring the Modbus IO Scanner

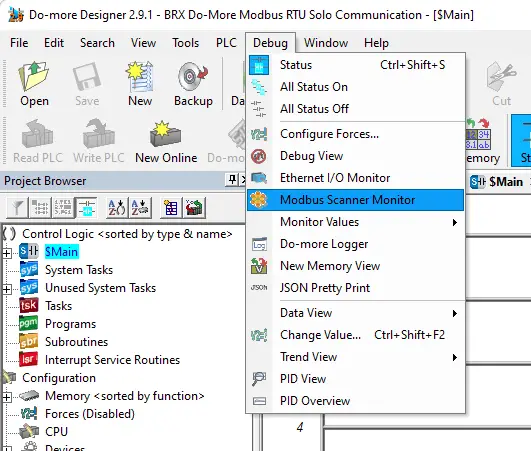

Select Modbus Scanner Monitor from the main menu | Debug.

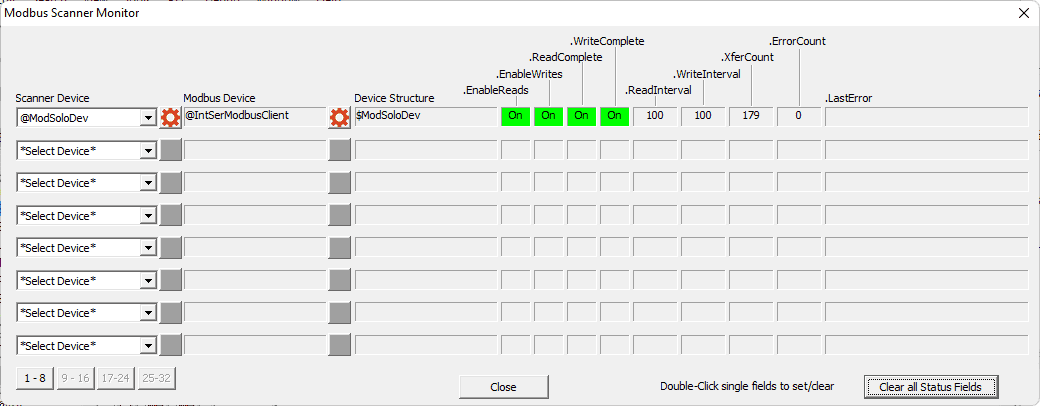

We can quickly see our Modbus Scanner working.

We can quickly see our Modbus Scanner working.

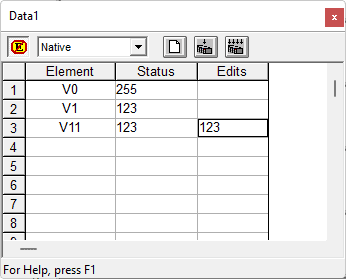

Using the Data View, we can all up the registers that we specified to see the PV and SV of the Solo temperature controller.

Using the Data View, we can all up the registers that we specified to see the PV and SV of the Solo temperature controller.

Change the value in V11. This will automatically send the new SV of the Solo. All done without the need for ladder logic or a unique timing code.

Change the value in V11. This will automatically send the new SV of the Solo. All done without the need for ladder logic or a unique timing code.

Watch the video below to see how to communicate using a Modbus IO scanner to the Solo Process Temperature Controller.

Download the BRX Do-More program here.

BRX Series PLC from Automation Direct – Power to deliver

Overview Link (Configure and purchase a system)

Manuals and Product Inserts (Installation and Setup Instruction)

Do-More Designer Software (Free Download Link) – The software will contain all the instruction sets and help files for the BRX Series PLC.

Watch on YouTube: BRX Do-More Simple Modbus Serial Communication

If you have any questions or need further information, please contact me.

Thank you,

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not challenging to learn and understand. We will walk through the numbering systems used in PLCs. These numbering systems include Bits, Decimal, Hexadecimal, ASCII, and Floating Point. To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now. The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is shown when you subscribe to ACC Automation.

The ‘Robust Data Logging for Free’ eBook is also available for free download. The link is shown when you subscribe to ACC Automation.