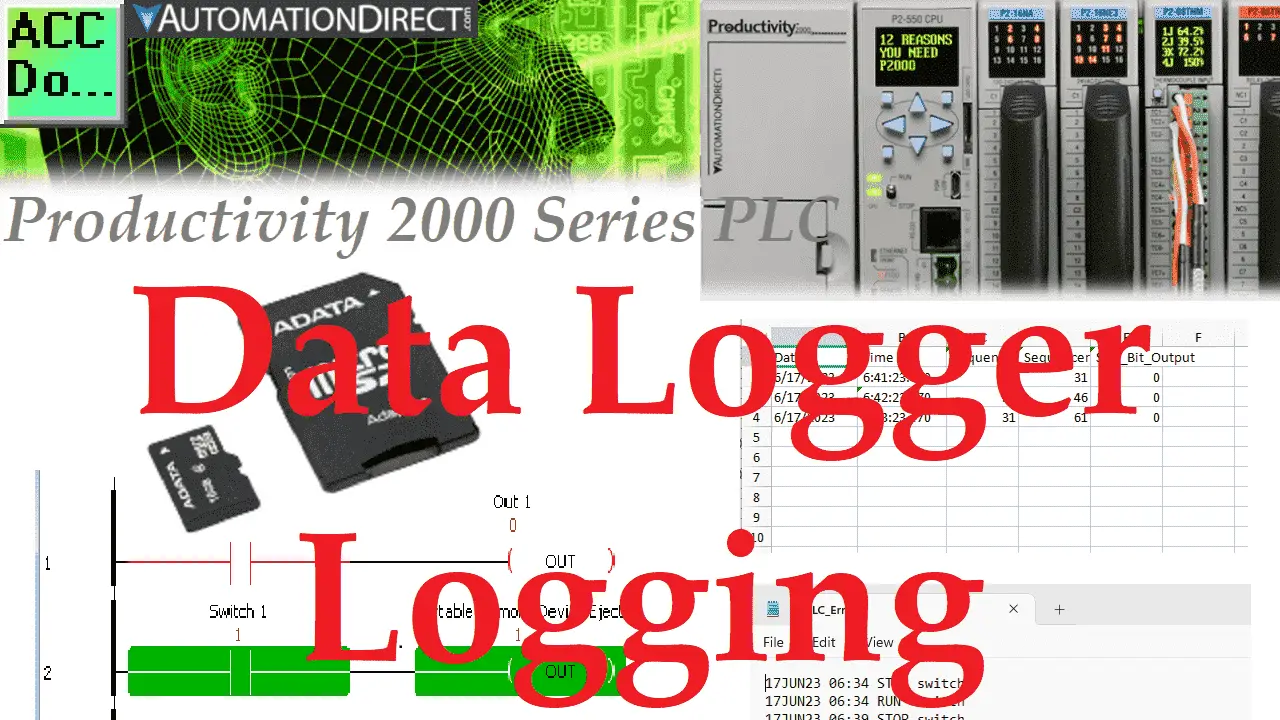

Productivity 2000 PLC Data Logger and Logging

The productivity series of PLCs has a built-in data logger. This accessible data logger will log up to 64 tag values on a USB (Micro SD) storage device connected to the CPU. The logs will be stored in CSV (Comma Separated Values) file format. Logging can be triggered by the rising edge transition of a … Read more