Accelerate Learning …

Accelerate Machines…

Accelerate Knowledge…

ACC Automation

In this Covid-19 world, we are continuing to adapt. Social distancing, mask-wearing, hygiene, etc are the way we currently live. Video conferencing with Zoom, Teams, and Google Meet are the norm in business today. Information is knowledge, and everyone more than ever wants to be able to see, control and summarize production data on a regular basis. Open intuitive technologies are available to communicate like never before. Industrial plant data is rapidly changing. Factory 4.0 benefits are being seen and everyone wants to take advantage. We are looking forward to the New Year and new possibilities for implementing your control solution.

In this Covid-19 world, we are continuing to adapt. Social distancing, mask-wearing, hygiene, etc are the way we currently live. Video conferencing with Zoom, Teams, and Google Meet are the norm in business today. Information is knowledge, and everyone more than ever wants to be able to see, control and summarize production data on a regular basis. Open intuitive technologies are available to communicate like never before. Industrial plant data is rapidly changing. Factory 4.0 benefits are being seen and everyone wants to take advantage. We are looking forward to the New Year and new possibilities for implementing your control solution.

Each year we like to take a few minutes and reflect on the past, current, and future of ACC Automation. You have helped us to build the site that you see today through questions, comments, and suggestions. Thank you.

Each year we like to take a few minutes and reflect on the past, current, and future of ACC Automation. You have helped us to build the site that you see today through questions, comments, and suggestions. Thank you.

ACC Automation – Past 2021 Industrial Control

Starting off the year we look at the updated firmware and instructions for the BRX Do-More series of PLCs. This includes an added web server and dynamic web pages that can be programmed.

HTTP Web Server – Video

Dynamic Web Pages (REST API) – Video

File transfer protocol (FTP) was implemented using the FTP Client on the BRX Do-More. A windows PC was set up and used as the FTP server.

File transfer protocol (FTP) was implemented using the FTP Client on the BRX Do-More. A windows PC was set up and used as the FTP server.

FTP Client Get Put – Video

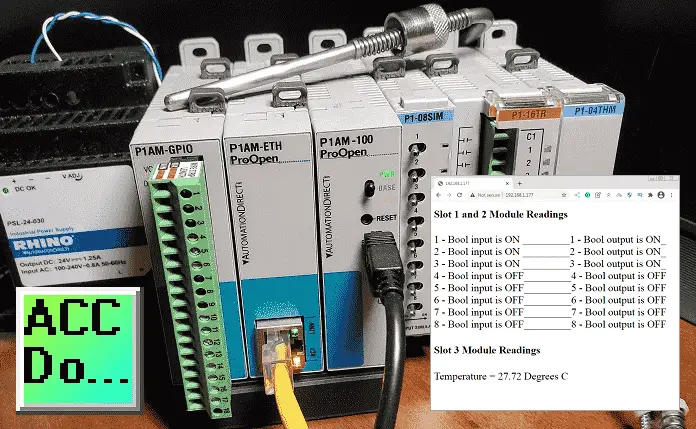

We finished our ACC Automation productivity open P1AM series by creating a web server. This industrial Arduino controller uses the input, output, and special IO from the Productivity 1000 Series as its own. The Arduino IDE or Productivity Blocks can be used to program this controller.

Arduino Web Server – Video

Arduino Modbus TCP Client to Click PLC – Video

Our Arduino Uno Super Starter Kit series was also finished with a post on LCDs. This Arduino Uno series took you through programming in C++ and how common electronic components work. It also helped to understand the programming of the industrial Arduino P1AM.

LCD Display – Video

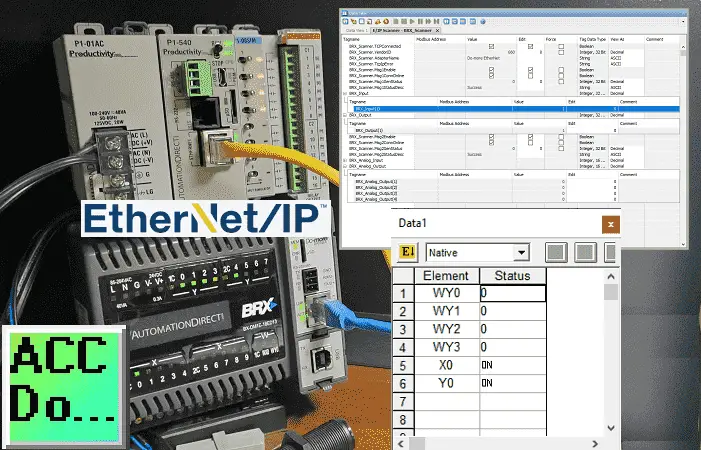

Remote inputs and outputs (IO) using other controllers were discussed. The ACC Automation Productivity Series PLC with its Ethernet/IP communication was used to communicate to a Click and BRX Do-More PLCs. Implicit Ethernet IP was used. The Productivity was set to be the Ethernet IP scanner and the other controllers were the Ethernet IP adapters.

Productivity 1000 Series PLC Click EtherNet/IP Remote I/O – Video

Productivity BRX Do-More EtherNet/IP Remote IO – Video

Node-RED is an enabling software for IoT. (Internet of Things) This means that we can communicate to control and read information from industrial equipment. This would include PLCs, temperature process controls, etc.

Logging of information to databases and analyzing this information is easily achieved. Through the following posts and videos on ACC Automation, we explained how Node-RED flows can be done.

Logging of information to databases and analyzing this information is easily achieved. Through the following posts and videos on ACC Automation, we explained how Node-RED flows can be done.

Installing the Windows Software – Video

Modbus RTU / TCP Communication – Video

User Interface – Dashboards – Video

SQL Database Log – Video

SQL Database Spreadsheet Connection – Video

Click Plus PLC MQTT Communication – Video

Click Plus Data Logging – Video

Do-More REST API – HTTP Request – Video

Installing Node-RED on Raspberry Pi 4 – Video

CH340/CH341 USB to Serial PC Installation – Video

Simple Click Data Logging – Video

Node-RED Modbus TCP Handling Errors – Video

Raspberry Pi Serial Port Programming – Video

Omron PLC Node-RED Serial Communication – Video

Node-RED is part of your Factory 4.0 control solution.

The Click PLUS PLC was introduced. This provided the following features to this still low-cost industrial controller.

The Click PLUS PLC was introduced. This provided the following features to this still low-cost industrial controller.

• Micro USB

• DHCP support

• DNS support

• Wi-Fi (programming and Modbus TCP)

• Bluetooth (Wi-Fi) provisioning

• SD Card (Data Logging)

• Data Logger

• Network Time Service

• MQTT (Publish/Subscribe)

• Required PLC Password

• Disable Ports

• Strong Password Support

• Disable Ping Response

• Encrypted Password Transfer

This new controller also came with improved software that is intuitive for new programmers. It now has a ribbon menu that is similar to all modern window interfaces. ACC Automation looked at some of the new features of this updated controller.

Installing the Software – Video

File Project – Click Retentive Registers Video

Click PLC Retentive Data Memory Registers – Video

Click PLUS – Establish Communication – Video

Click Plus Real-Time Clock – Video

Click Plus PLC MQTT Communication – Video

Click Plus Data Logging – Video

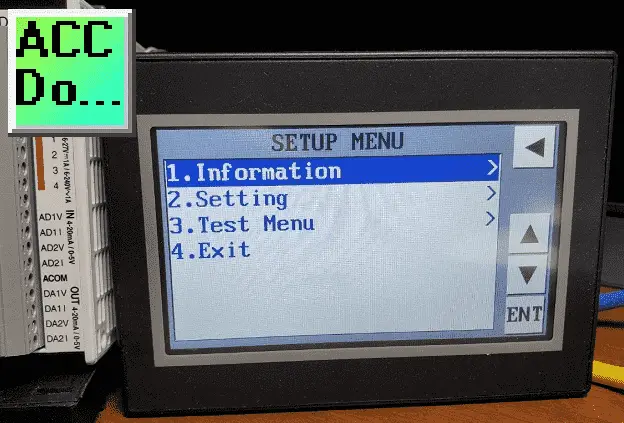

There were several other posts throughout the year that answered your questions or further explained a feature. The C-more micro quick start comes to mind that has helped understand how this human-machine interface (HMI) works. It demonstrates connecting this HMI to a PLC.

There were several other posts throughout the year that answered your questions or further explained a feature. The C-more micro quick start comes to mind that has helped understand how this human-machine interface (HMI) works. It demonstrates connecting this HMI to a PLC.

C-More Micro Program Quick Start – Video

ACC Automation – Industrial Control Current

Currently, we are in the process of our PLC Training Series and our EasyPLC Software Suite Series. Based on your information from a survey on our YouTube channel the PLC training series discusses the development of a PLC. The main components of the PLC controller are broken down and explained.

EasyPLC software suite is a complete PLC, HMI, and Machine Simulator Software package. We are currently looking at the machine simulator and connecting this to the Click PLC, BRX Do-More PLC, and Productivity Series PLCs. The machine simulator is a virtual 3D world with real-time graphics and physical properties. This will help in learning or testing PLC control.

EasyPLC software suite is a complete PLC, HMI, and Machine Simulator Software package. We are currently looking at the machine simulator and connecting this to the Click PLC, BRX Do-More PLC, and Productivity Series PLCs. The machine simulator is a virtual 3D world with real-time graphics and physical properties. This will help in learning or testing PLC control.

Easy PLC Installing the Software – Video

Click PLC – Easy Transfer Line Programming – Video

Productivity PLC Simulator – Chain Conveyor MS – Video

BRX Do-More PLC – Box Selection Program – Video

2022 Industrial Control – ACC Automation

2022 will prove to be an exciting time. We will continue with our two current series with additional examples of this 3D simulation of the process. This will be done with both the physical PLC hardware and the free PLC simulators from Do-More Designer or Productivity Suite.

The ACC Automation Productivity 2000 series PLC will show you how to implement this controller within the Productivity family of PLCs. (PACs)

The ACC Automation Productivity 2000 series PLC will show you how to implement this controller within the Productivity family of PLCs. (PACs)

Further Node-Red flow programming and implementation examples will be demonstrated. This will include a discussion of the “Data Hub”, “Unified Name Space”, etc. We will also continue by looking at the MQTT communication protocol used with the IIoT.

As always we will be answering your questions and applications so you can quickly implement your control solution.

As always we will be answering your questions and applications so you can quickly implement your control solution.

Watch on YouTube: ACC Automation 2021 Review – Industrial Control

If you have any questions or need further information, please contact me.

Thank you once again for supporting the website in 2021!

Garry

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimals, Hexadecimal, ASCII, and Floating Points.

To get this free article, subscribe to my free email newsletter.

Use the information to inform other people how numbering systems work. Sign up now.

The ‘Robust Data Logging for Free’ eBook is also available as a free download. The link is included when you subscribe to ACC Automation.