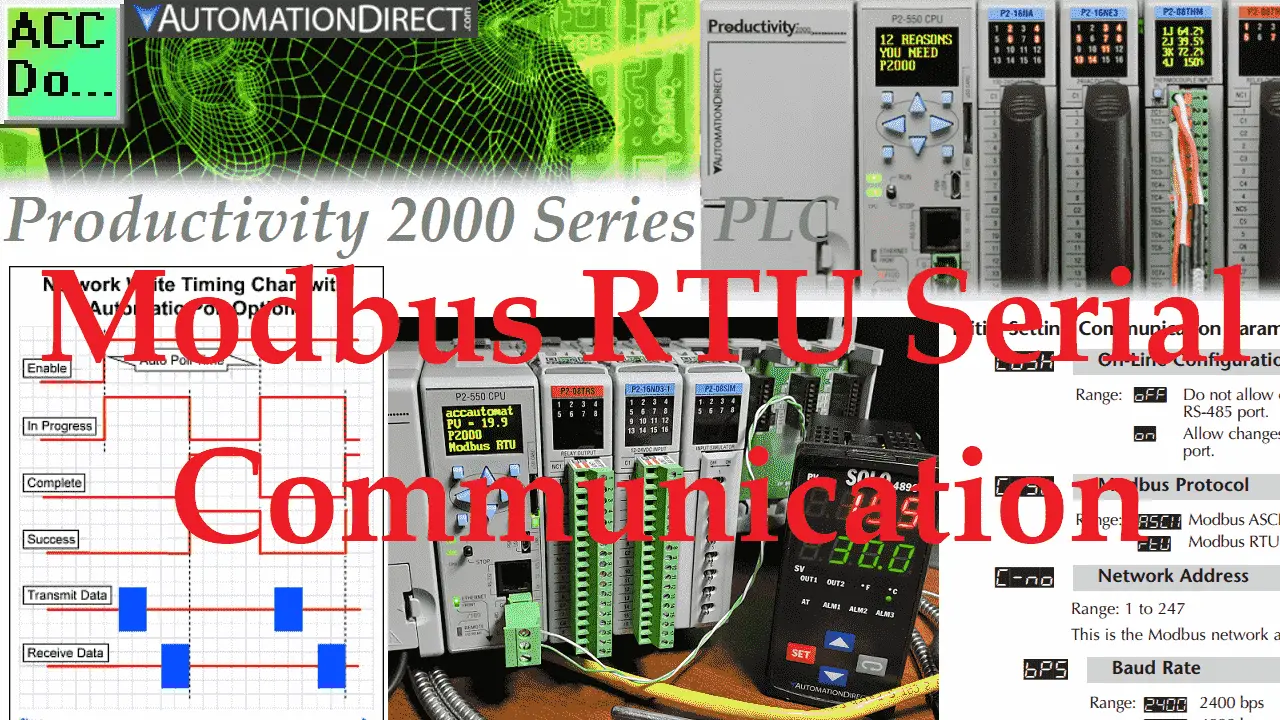

Productivity 2000 Series PLC Modbus RTU Serial

The Productivity 2000 series of PLCs has five built-in communication ports for easy connectivity to your PC or various industrial networks. Serial protocols like Modbus RTU can be utilized with the RS232 or RS485 ports on this PLC. Modbus RTU (Serial) is an open (published) protocol that uses the Master / Slave architecture. It’s a … Read more