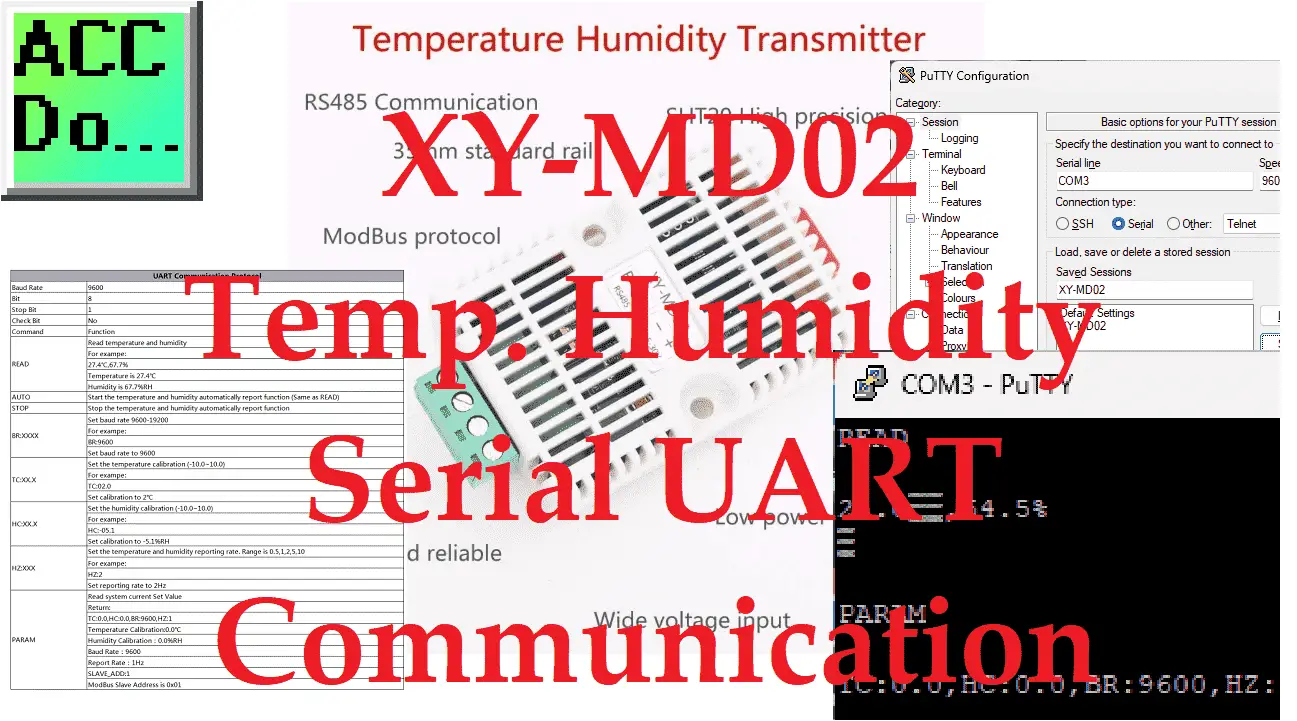

XY-MD02 Temp Humidity Serial UART Communication

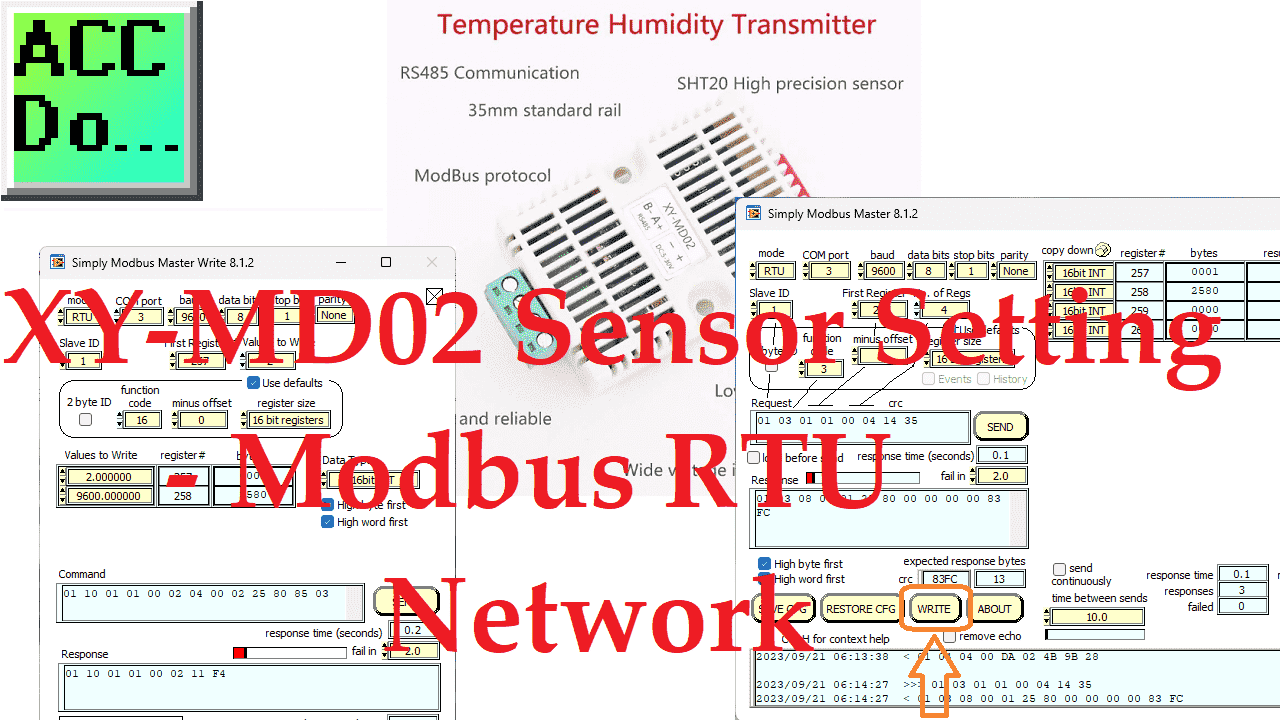

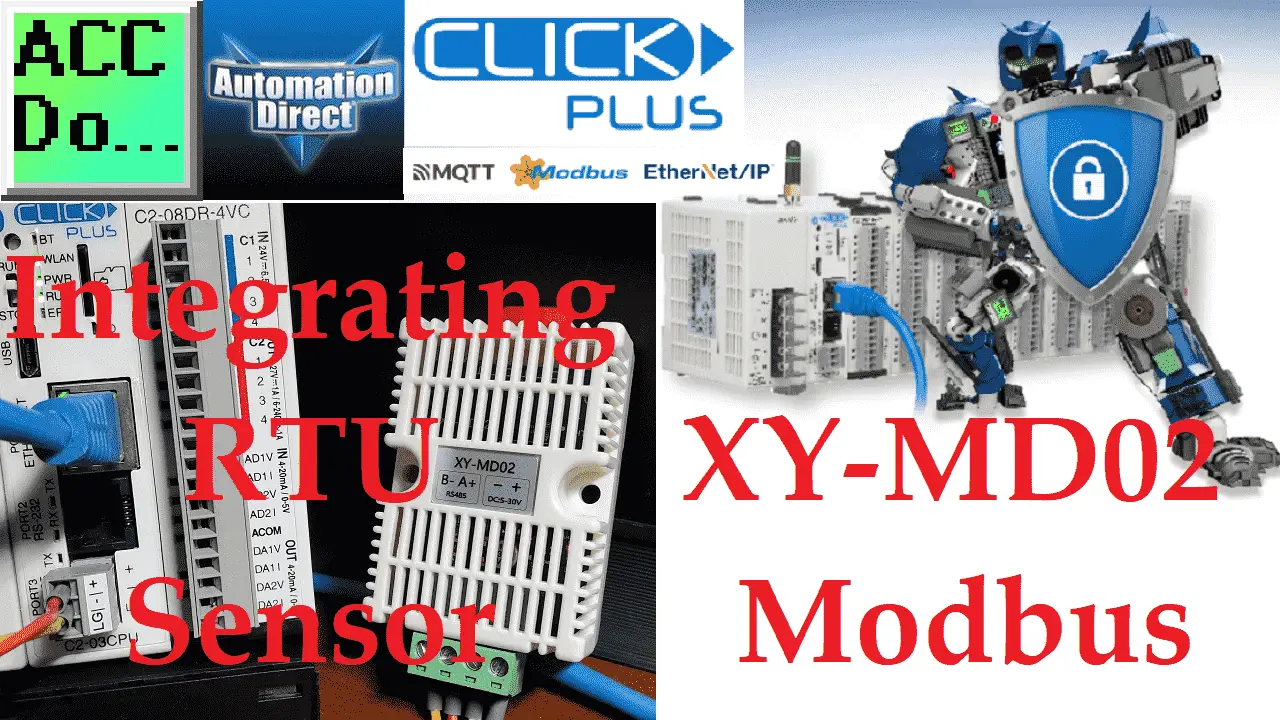

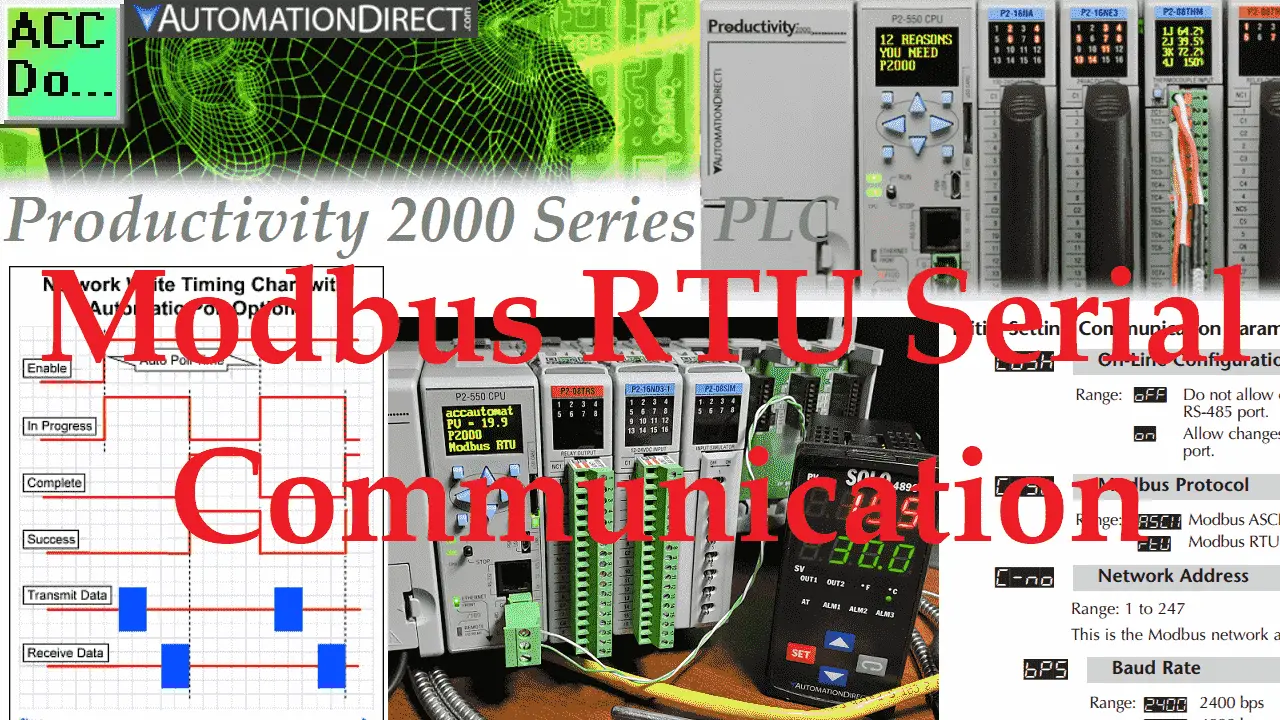

To get started with the XY-MD02 temperature and humidity sensor, we will be using the program PuTTY for serial communication. We will use RS485 serial communication to establish a connection and show how to read the values and parameters of the XY-MD02 sensor effectively. Additionally, we will explore the automatic polling feature, which allows for … Read more