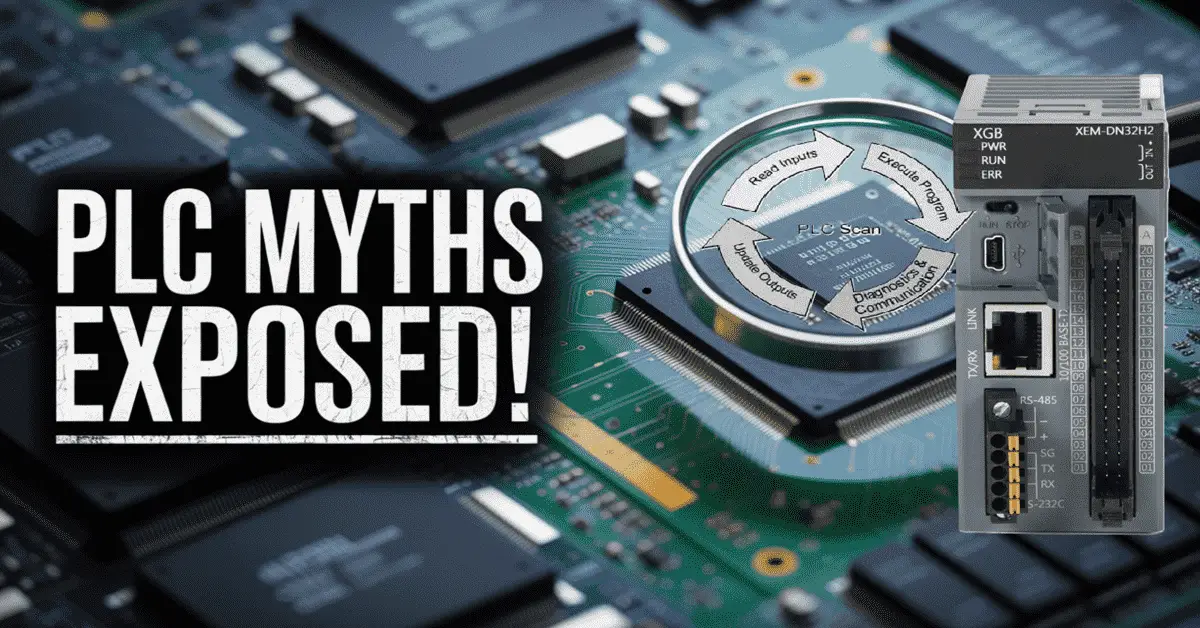

Exposing the Secrets of PLC Programming Myths!

In today’s rapidly evolving world of manufacturing and automation, it’s essential to understand how Programmable Logic Controllers (PLCs) operate. However, many common misconceptions about PLCs can create confusion. We will clarify five widespread myths about PLCs, focusing on their unique functions, programming challenges, and the need for a thorough approach to their use. By addressing … Read more