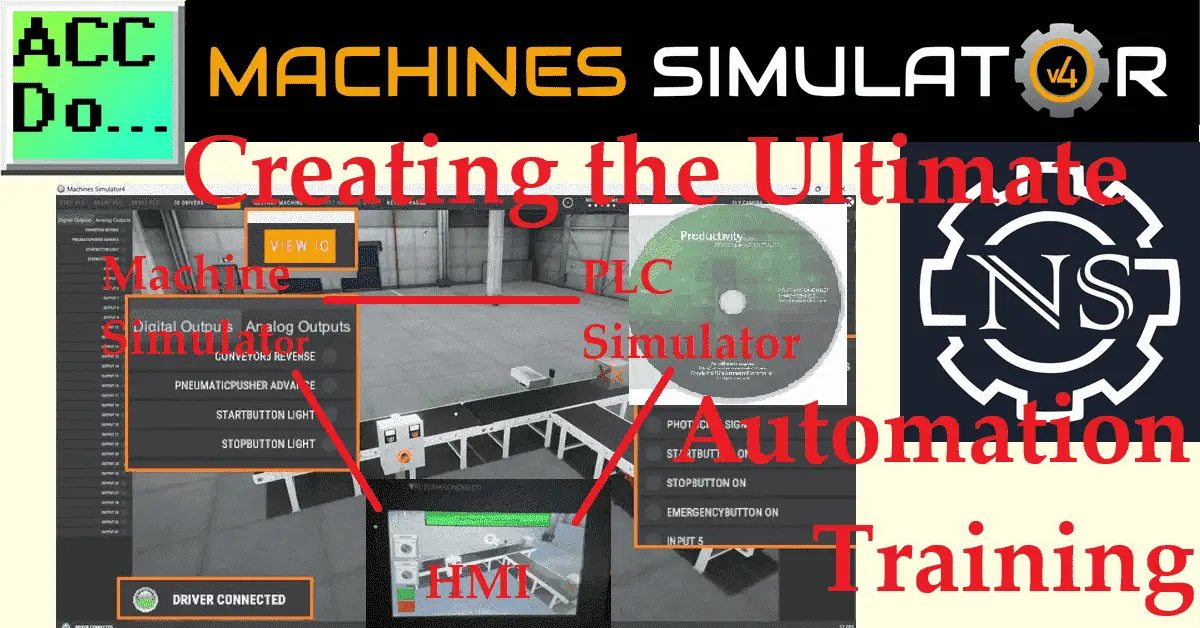

Creating the Ultimate Automation Training Setup1

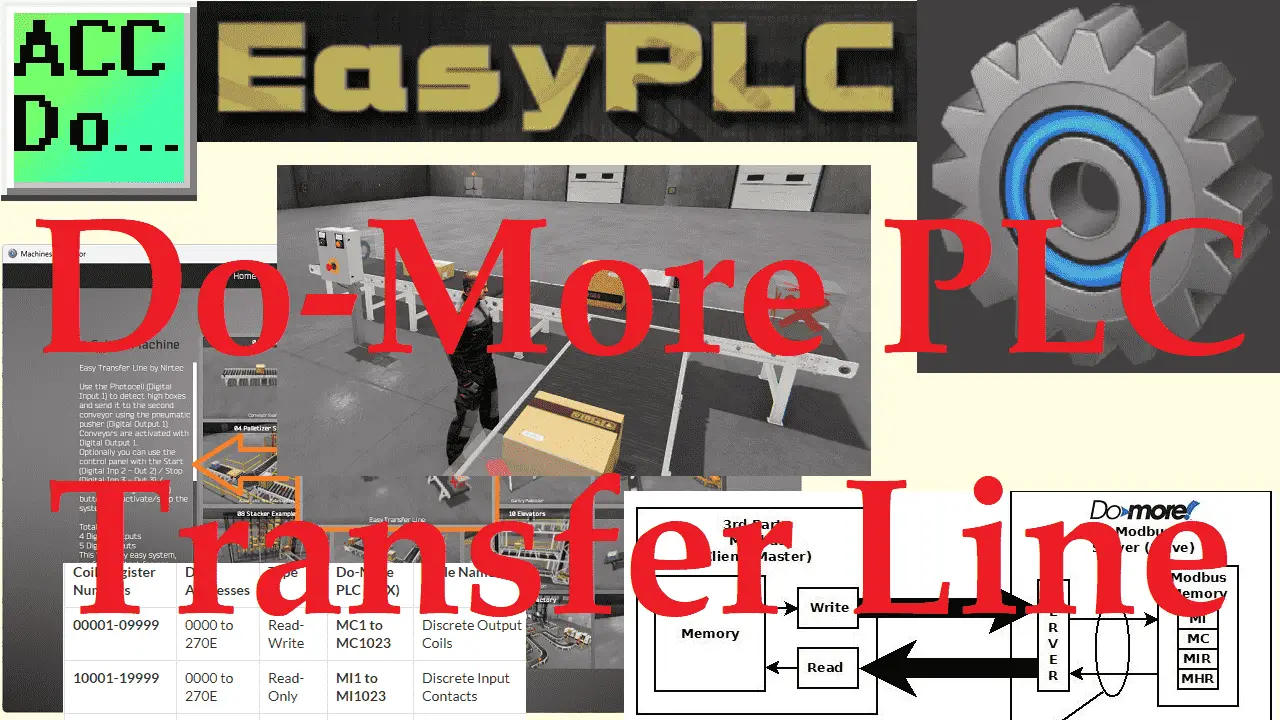

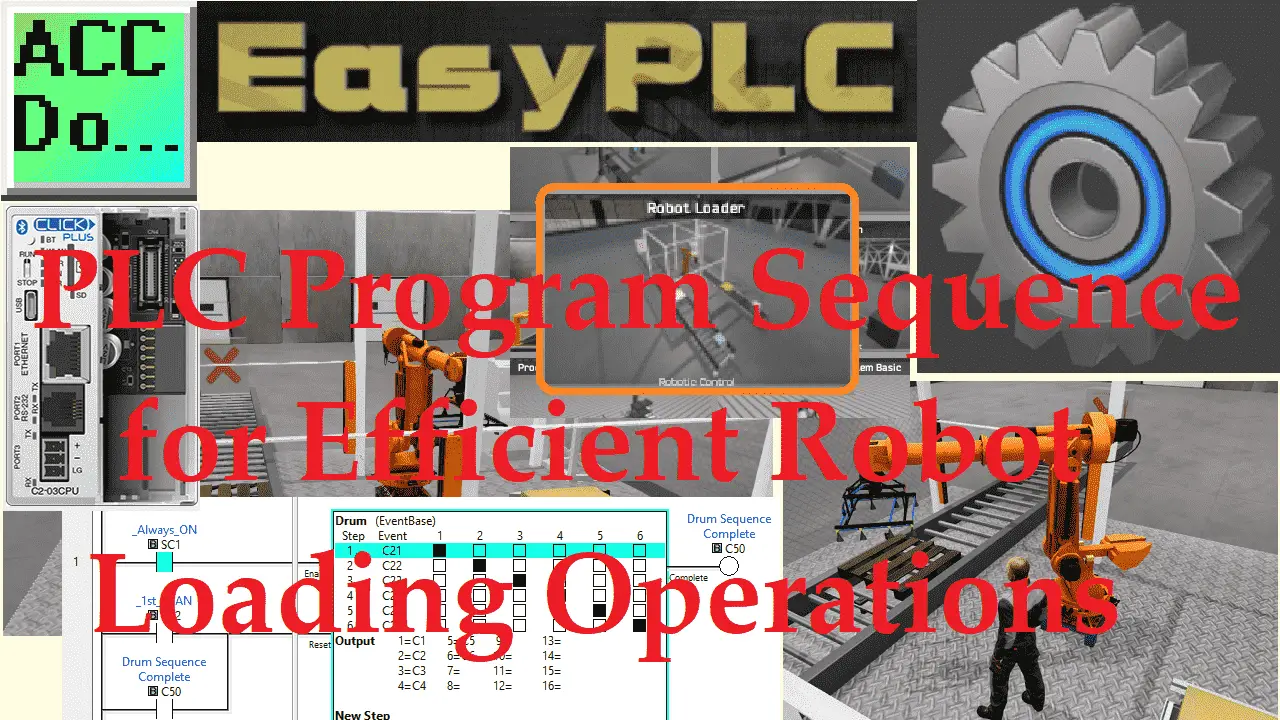

Only 31% of businesses have fully automated at least one function (McKinsey). This means a huge demand for automation and creating a training environment exists. Typically, automation training and hands-on programming take time and a lot of resources, but this is no longer the case. Creating an effective automation training environment tailored to your industry … Read more