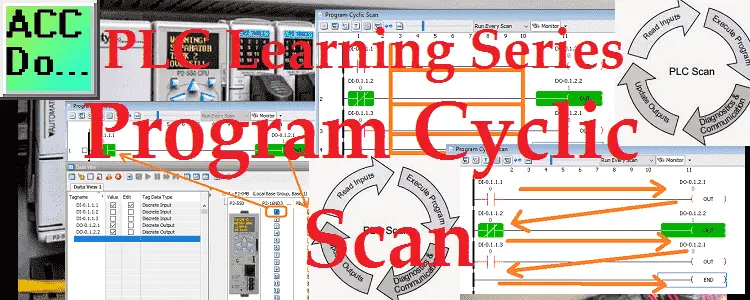

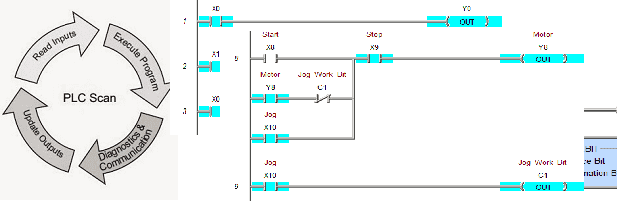

PLC Learning Series – Program Cyclic Scan

Programmable logic controllers (PLC) use a cyclic scan. The time that it takes to complete one scan is called Scan Time. Typical scan times range from 10 milliseconds to 10 microseconds. This translates from 0.01 to 0.0001 seconds per PLC scan. Understanding how the program scan will help us in programming and troubleshooting the PLC. … Read more