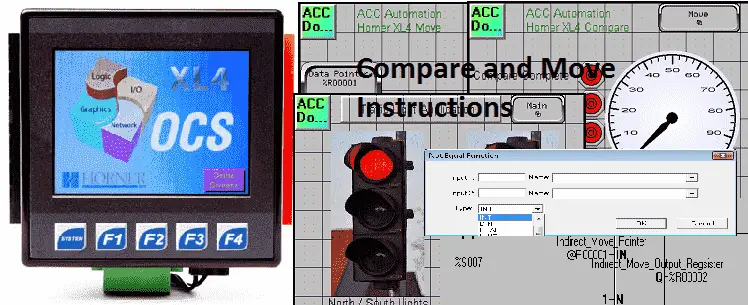

Horner XL4 Compare and Move Instructions

Compare and move instructions in the Horner XL4 OCS all-in-one controller can be very powerful. We will be looking at how to use these compare and move instructions. Combining these two instructions to build a sequencer, we will apply this to an application example. Our application will be a simple traffic light. The HMI screen … Read more