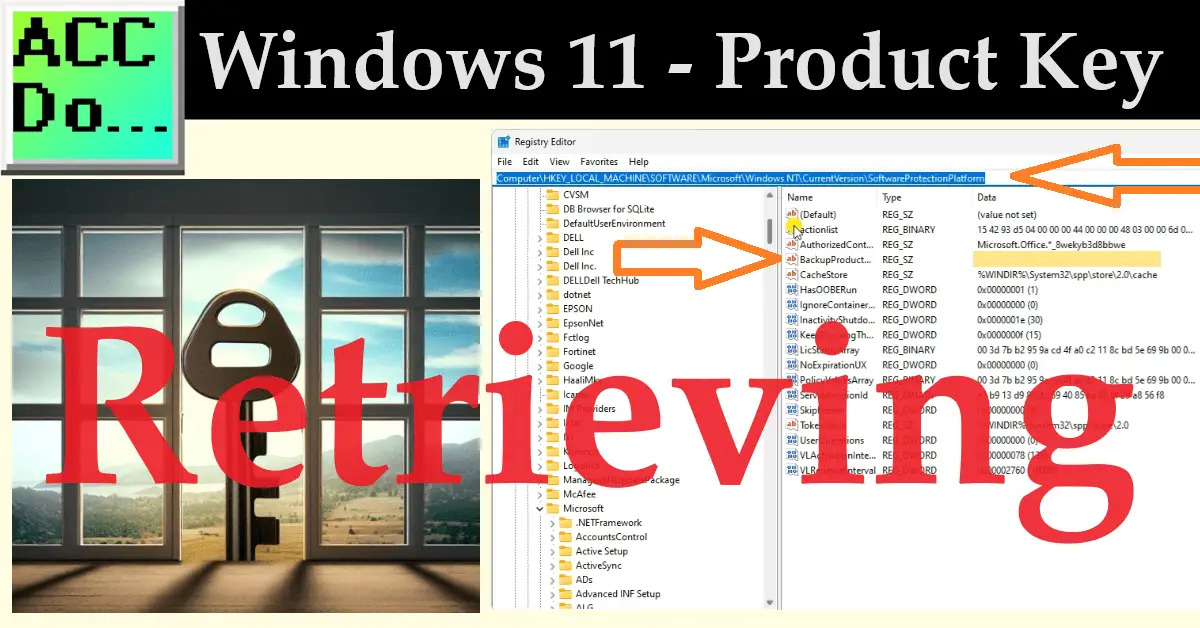

Retrieving Your Windows 11 Product Key

Retrieving your windows 11 product key is easily done using the windows registry editor. If you have a licensed version of Windows, it can be quite frustrating to not be able to find the product key when you need it. You may have purchased a new computer that comes with Windows 11 preinstalled, but the … Read more