Master Industrial Temperature Control with Modbus Magic

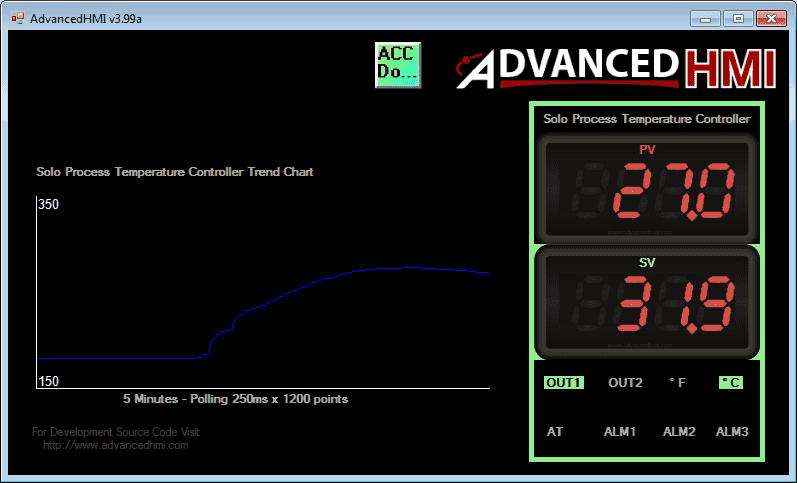

Modbus RTU will be the serial (RS485) method in which we will communicate between the AdvancedHMI Screen and the Automation Direct Solo Process Temperature Controller. We can address up to 247 (Solo 1 to 247) devices on this master-slave protocol. A maximum of 32 devices (Nodes) on the network can communicate to the master. A … Read more