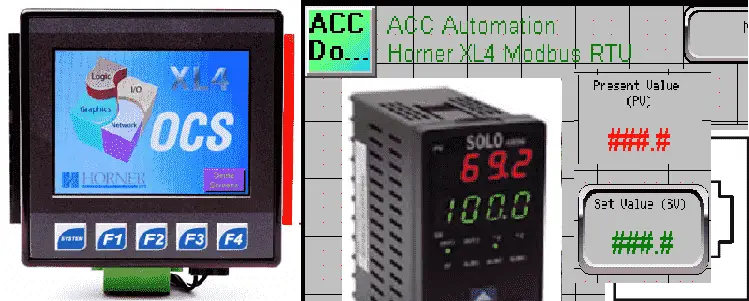

Horner XL4 Modbus RTU Instructions

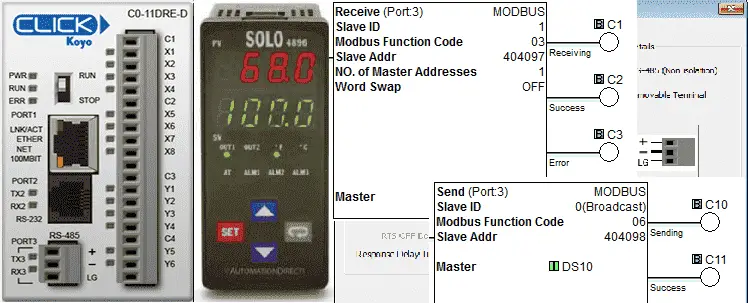

We will now communicate Modbus Serial RS485 from the Horner Master controller to the Solo process temperature controller. The Horner APG XL4 all in one controller has several different ports for communications. We have both serial and Ethernet-type ports that can be used for many different protocols. These protocols can be downloaded from the Horner … Read more