ACC Automation 2016 Review

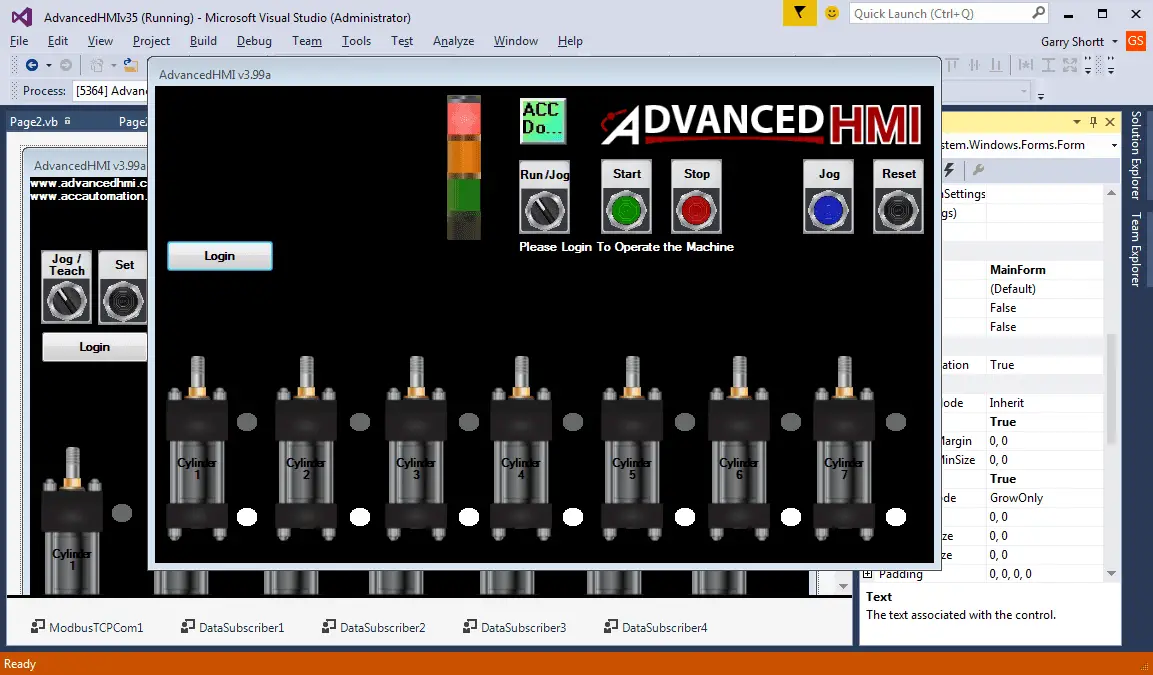

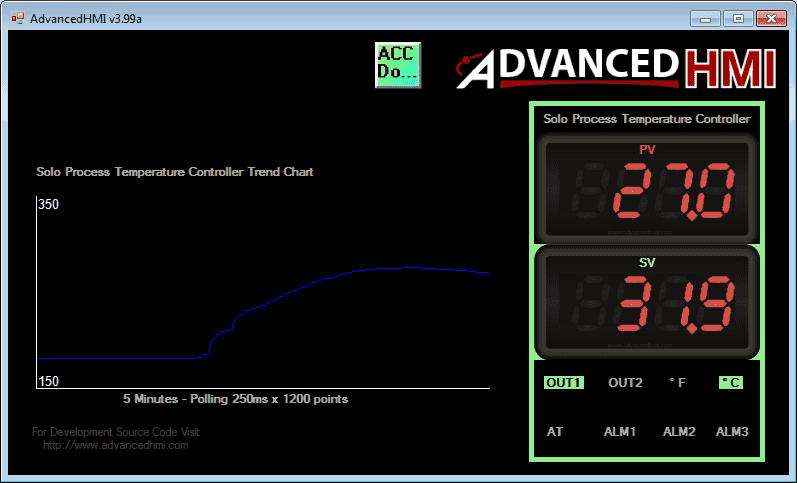

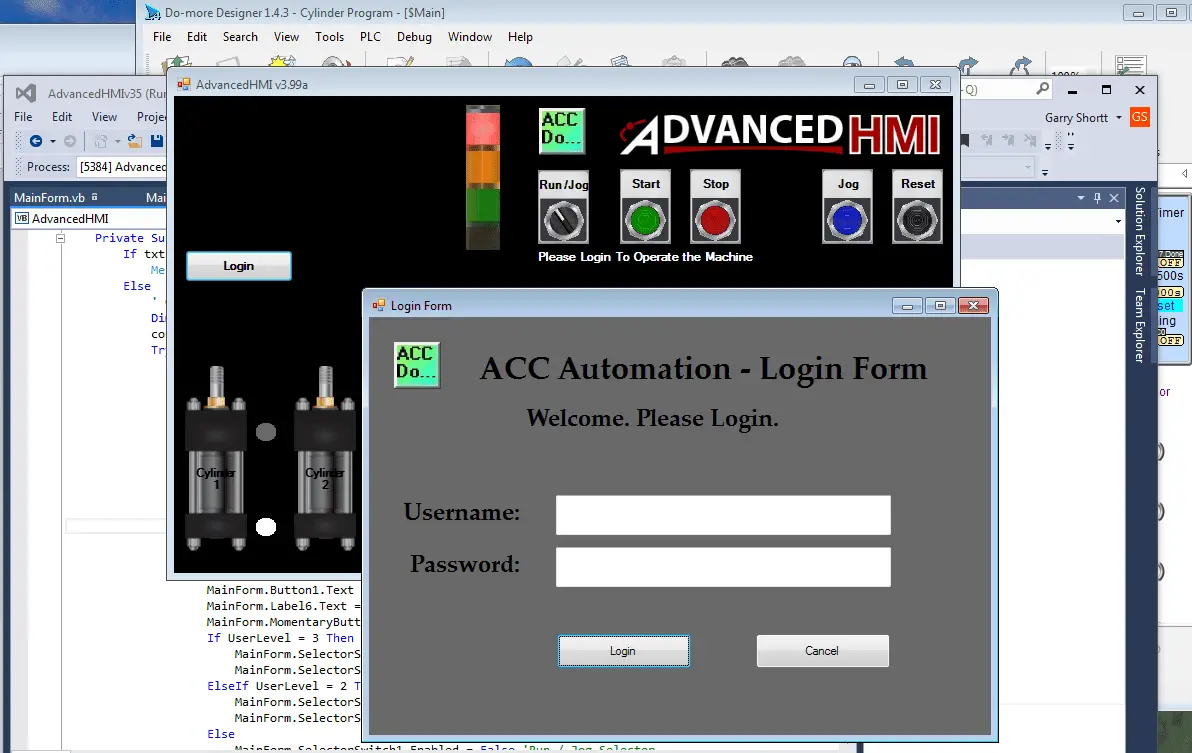

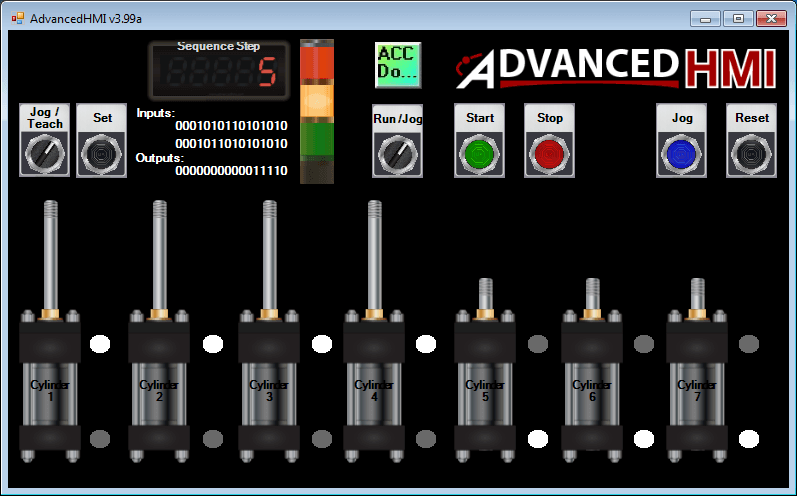

Acc Automation We would like to take a few minutes and reflect on the past, current and future of ACC Automation. You have help us succeed in our best year yet. Starting off we learned how to: Create a PLC with HMI Training and Learning Environment Free – Utilized the Do-More Designer Software and the … Read more