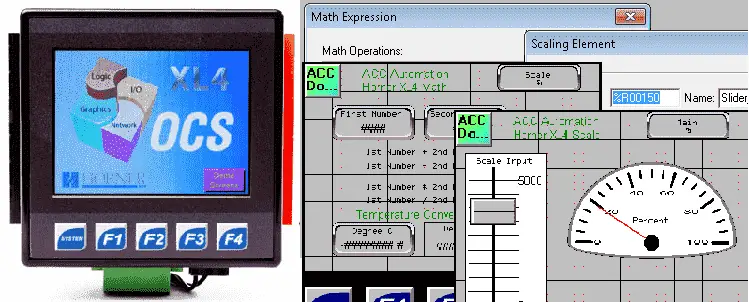

Master Advanced Math Operations in Horner XL4 PLCs Today!

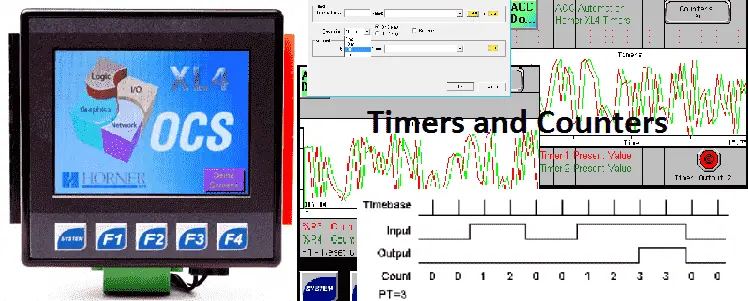

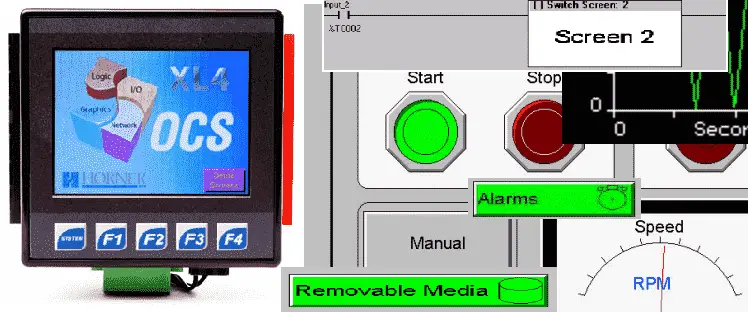

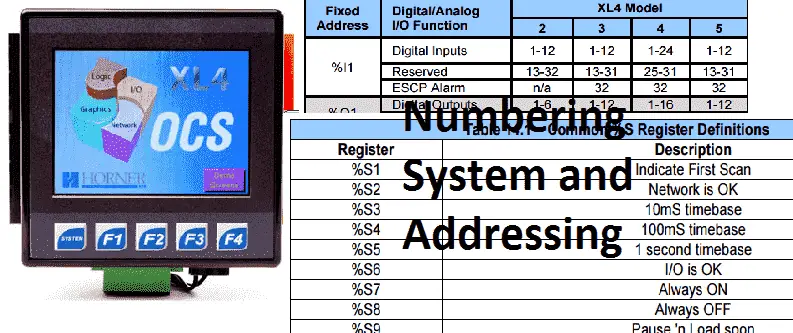

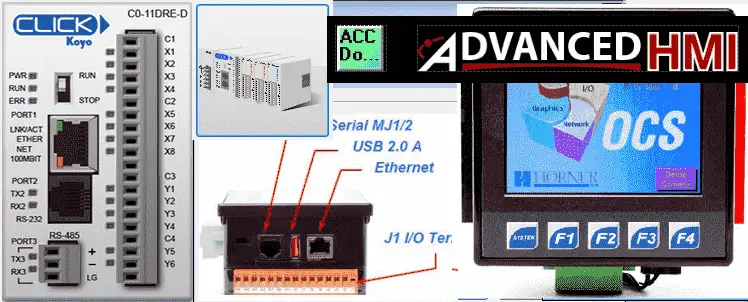

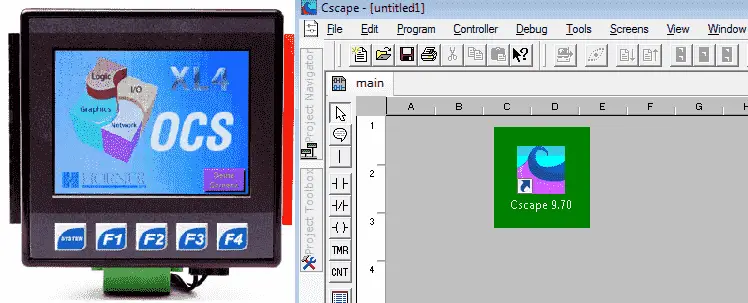

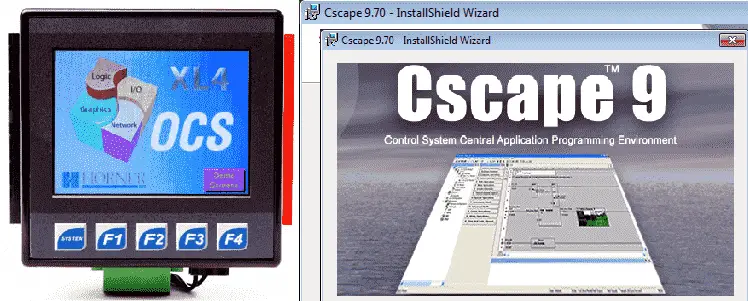

Math instructions in the Horner APG XL4 OCS all-in-one controller are broken down into Basic Math Operations and Advanced Math Operations. Basic Math Operations include the following: Math Equation Element, Add, Subtract, Multiply, Divide, Modulo, Square Root, Absolute Value Advanced Math Operations include the following: Power of X, Base 10 Logarithm, Power of e, Natural … Read more